Krone has launched a new wholecrop direct-cut header — not only is it wider, but it also has integrated transport running gear. We had the opportunity to get an early first look.

KEEPING IT BRIEF

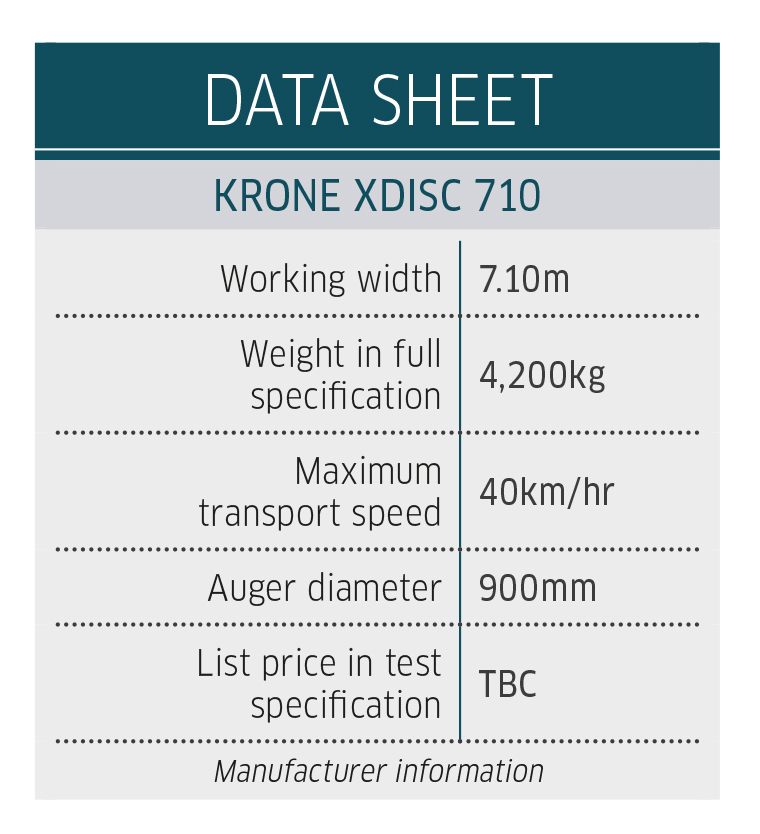

- Has its own integrated transport running gear; a separate header trailer is no longer needed.

- Changing from field to road can be done in a few minutes.

- The XDisc 710 weighs 4,200kg.

With the new XDisc 710, Krone is responding to market demands for a direct-cut header with a larger working width that can be better matched with the potential output of today’s higher-capacity foragers.

Yet there is more to the XDisc story than just increasing the working width up from the existing 6.20m version.

Some background. There’s now a bigger area of alternative crops being grown to feed the likes of anaerobic digesters, crops that for one reason or another are better harvested directly rather than with a separate mowing pass. So, the designers have looked at other ways they could improve on performance and efficiency rather than just relying on taking a bigger bite of crop with the new model’s 7.10m working width.

Powerful drive

Compared with the 620, the 710 also has a larger main gearbox to deal with the extra horsepower, and, because it is designed for more oomph, there is no overload protection here.

Drive is then split using pto gearboxes, the right transmitting power to the centre of the mower bed while the auger is driven from the left-hand side. Disc speed on the cutterbar is constant, with the only variation coming from the forager’s engine speed. The auger, on the other hand, can be swapped by moving the drive shaft to one of the three stubs on the gearbox allowing it to be better matched with the chopper’s intake speed. This will help optimise the crop flow, especially when looking for the shorter chop lengths that are often now required.

The auger is protected against overload by a star ratchet clutch. At the left-hand end of the header, a chain transmits the drive from the gearbox to the auger. This chain has an auto tensioner, and there is an oil reservoir and pump to keep the chain running sweet during work.

Crop flow

Krone has stuck to what it knows on the new XDisc using two of its familiar EasyCut beds. The floating 900mm diameter auger ensures the cut crop is always cleared away from the bed. The auger’s height can be manually adjusted in three stages.

To help tackle entangled crops, there is the option of side knives £6,795. The operator can swing these in/out of work hydraulically by using the multifunction buttons on the Big X’s joystick. Only the knife that is currently cutting through crop is in its vertical working position, whereas the other knife retreats to its horizontal position. The benefit of this, is that the mower’s full working width can be used without having to worry about the knife on the openside lopping off any overhanging ears that may have flopped over since the last pass. Headland turns are managed by pressing a button twice, but Krone plans to reduce this to one press.

Another feature is the crop press roller, which ensures a smooth crop flow in taller crops. A new feature on the XDisc 710 is the central adjustment for the skids. Two of the four skids can be adjusted to three different heights by operating a linkage with a supplied spanner.

Integral running gear

But the biggest innovation is the integrated transport chassis. You don’t need a separate trolley, and getting going is made significantly quicker. When changing from road to field, just lower the parking stand on the crank, disconnect the light plug and open the clevis hitch.

Line up the forager and then couple up the header to the intake unit and lock it in place (hydraulically as an option). The hydraulics and electrics are connected manually. Once this is done, the folding sequence is carried out hydraulically: the drawbar folds up, the transport axle swings to the side onto a frame and then this folds up and out of the way. All this is executed with the touch of a button. When folded, neither the drawbar or axle obstruct the view or contact the crop.

Because the XDisc running gear doesn’t have any brakes, it must be secured with a chain to the forager before the combination heads out onto the road. EU type approval considers the mower a trailed machine — similar to a square baler. As such, it is permitted to run at 40km/hr on public roads.

Quick changeovers

The new transport chassis makes a noticeable difference to the set-up times. In our case, the entire changeover took about four minutes, which can be reduced even further once the operator is familiar with the process. Another couple of plus points is that you don’t need to do as much shunting in the field, and there is no trailer that can be potentially left in the way.

Header attachment/removal and operation are simple. All the setting options are easily accessible. However, we would like to be able to make the changes without any tools. In its transport mode, the mower sits well on the road even at 40km/hr and follows the forage harvester nicely.

Field work

Our on-test mission was to cut triticale for a biodigester; this farm harvests around 100 hectares of the crop each year. The average yield was 35t/ha and we were chopping the crop to 4.5mm with the Big X 780 reaching its limit at around 5km/hr.

We opted to connect the auger’s pto to the medium speed shaft to match the short chop length; the auger-trough clearance was also set midway to gain more space and help to control the flow of the high-yielding forage. As a side note, we’d recommend the chute extension on the forager for improved trailer filling with the wider header.

Summary

Krone has come out with a new, wider XDisc wholecrop header to make the most of bigger foragers. Overall power requirement per metre working width has been reduced, thanks to the split mower bed as well as the speed and trough clearance adjustment on the auger.

According to Krone’s own measurements with their flagship Big X 1180 forager, throughput increased by about 20% and fuel consumption dropped by 10% compared to the XDisc 620. Changeovers are much faster, too, thanks to the integrated chassis and simplified setting options. In full spec, the new header weighs 4,200kg. List price for the XDisc 710 has yet to be finalised.

The farm we visited will use the XDisc to cut 100ha of triticale and 120ha of silage each season, as the farm manager no longer sees any downside compared to the maize header in terms of working width and set-up times.

Sebastian Rüther

For more up-to-date farming news click here and subscribe now to profi and save.