This latest update not only gave the S series a new cab, but John Deere has also taken automation of its single-rotor combine range to a new level. Our driving impression explains how it all works.

KEEPING IT BRIEF

- New generation S7 gains the styling from the X9 as well as the cab and 13.6-litre JD14X engine.

- Predictive Groundspeed Automation control is also completely new.

- Overall, Deere states up to 20% more performance largely thanks to increased automation.

The first thing that catches the eye about the S Series is its styling, which was co-designed by BMW designers … and that also includes the cab. This familiar piece of harvest office space comes from the X9, which we are now familiar with (see profi Harvest Special 2020).

One key reason for this is the CommandPro controller and the G5Plus terminal, which is complemented by a new corner post display. Another is that amenities such as the leather- clad seat that boasts heating, ventilation and a massage function can now be enjoyed on the S7, too. The whole package is rounded off by LED all round lighting, and, last but not least, the electric door closer — you only have to lean it close, and the door will automatically shut the rest of the way on its own.

But where things get really exciting is when it comes to automation. First up, there is the Terrain Settings Automation (previously known as Active Terrain Adjustment). This feature controls the sieves and fans relative to the combine’s position, uphill or downhill. Then there is Active Slope Automation. This refers to a conveyor belt, mounted behind the grain pan at right angles to the direction of travel, that feeds the crop uphill to ensure that the sieves are evenly loaded. The belt speed and sense of rotation are controlled depending on the steepness of the slope.

Automation levels

Ground Speed Automation, which was part of Harvest Smart, controls the forward speed by using information such as the thickness of the mat in the rotor, the engine load and the biomass maps and loss measurements.

Harvest Settings Automation builds on this. This clever feature relies on cameras that are installed in the returns system and the grain elevator and allows operators to set up limits for losses, crop purity and damaged grain percentage.

The only thing that is somewhat confusing here is that the target values are not shown as percentages but on a scale either from 1 to 10 or from 1 to 100. The operator slides the point to a position on the scale where the grain quality, chaff/straw percentage and losses meet the requirements. As pretty as this is, we would still appreciate a system that integrates the use of trays in the evaluation of these losses.

Stereo cameras on the roof

Predictive Ground Speed Automation, which is essentially the predictive and automatic control of the forward speed, is completely new.

To achieve this, the system employs two stereo cameras, left and right of the cab roof, to predict the volume and condition of the crop before automatically altering forward speed to match e.g. reducing the speed when approaching a patch of lodged crop or upping the pace when driving in a tramline.

And since this predictive control means there is no need to keep some extra engine power back in reserve, the system allows you to work the combine at its full engine load. This is why John Deere is suggesting 20% higher throughput and seasonal performance gains. That’s an impressive claim.

However, the information from the cameras is not being used (yet) to automatically tweak the header functions such as reel height and speed.

All other functions, like the forward speed, opening the sieves, concave clearance, rotor and fan speeds are controlled automatically by Harvest Settings Automation. The grain quality is monitored via the cameras in the grain and returns elevator.

This level of automation naturally comes at a price. For example, the Predictive Ground Speed Control package complete with the two stereo cameras on the cab roof costs around £13,500. The complete harvesting automation system with cameras in the elevators etc., costs around £20,891.. Add to this an annual license fee of £2,841 for updating software and enhancing the auto functions.

Further details in a nutshell

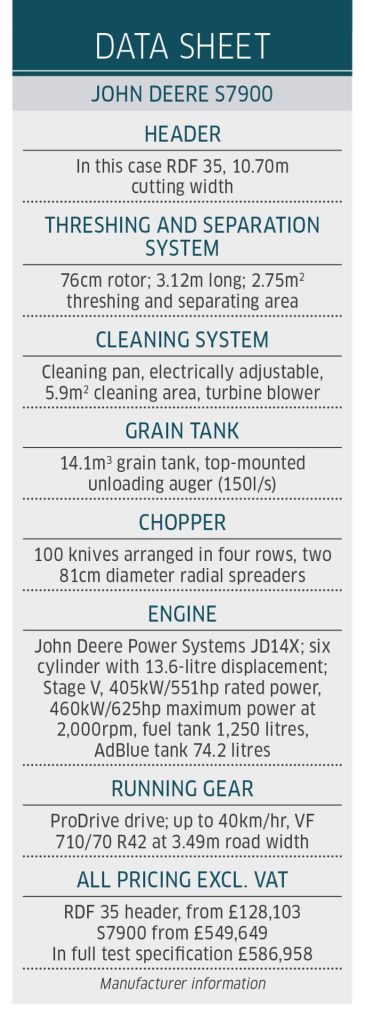

- There’s a total of 4 models, from the S7700 (max 467hp) to the S7800 (547hp), S7850 (579hp) and the S7900 (625hp). The S7850 will be the most popular in the UK.

- The S7700 has the 9.0-litre engine; all other models get the 13.6-litre JDX14.

- Like the X, the S has a permanently installed mussel sieve at the end of the top sieve and loss sensors behind the four sieve lines underneath it.

- Also new are the two additional side scoops at the end of the cleaning pan that stabilise the air flow.

- There is a new humidity sensor. And the optional HarvestLab NIR sensor is available for all models.

- The unloading rate of the X9 sourced auger is 150 litres/sec. There is also an adjustable spout. Seed producers will be pleased with the new quick-cleaning caps on the grain tank.

- The chopper unit, too, is sourced from the X9, whereas the mechanically driven radial spreaders have been retained but have been modified for the new generation of Deere harvesters.

T5 AND T6 WITH NEW CAB

In addition to the new cab and new styling, there are also some new features for the 5- and 6-walker machines. The grain tank volume increases to 13.5 and 11.5m3 and the larger discharge auger with 150l/s and adjustable spout are fitted. There is also a new straw chopper for the T5/T6 and electrically adjustable counter-blade. Also new are the automatic adjustment of the fan/sieves on the move and ‘Ground Speed Automation’.

Summary

As automation is making rapid progress, it achieves great leaps in boosting the efficiency of combine harvesters.

Even though a motivated operator may be able to push the combine to achieve higher throughput, most users will struggle to do this consistently over a full working day, and the new technology will never tire. Whether this justifies the additional investment of no less than £20,891 for the full package depends on the individual farming operation.

Should it indeed be possible to boost your output by 20% every season, you should be able to cope with the additional annual licence fee of £2,841 for predictive combining.

Hubert Wilmer

For more up-to-date farming news click here and subscribe now to profi and save.