Weycor has upgraded its proven 15t-class shovel for farm work. We took the agri-spec loader on to a maize clamp.

KEEPING IT BRIEF

- Diesel consumption was 14l/hr when we were on clamp work.

- Its pushing power impressed us.

- Behind the Weycor name is the more familiar Atlas brand, which has been building loading shovels in Wildeshausen for over 50 years..

- Vaughan & Sons is the distributor in Ireland. There is no importer for the UK as of yet.

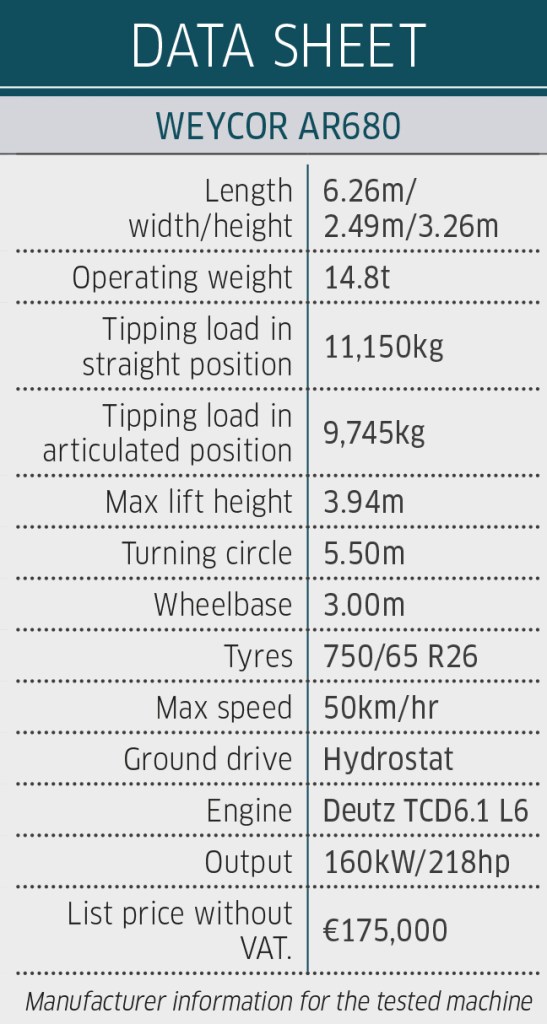

The industrial version of Weycor’s AR680 wheeled loader has been kicking around on construction sites and quarries since 2016. Now it is gearing up for a bigger push into the silage clamp sector with a custom package just for the job. The demo AR680 surprised us, and not just with its maize pushing ability.

Engine, transmission

Under the bonnet is a six-cylinder, 6.0-litre, Deutz engine that develops 160kW/218hp. It ticks the box for Stage IV emissions with the help of SCR and a diesel particulate filter. A large radiator with a reversible fan is part of the agricultural package.

Drive is hydrostatic up to 50km/hr with two drive motors. Both work up to 14km/hr, at which point one motor swings out enabling stepless driving up to maximum speed. For €1,400 extra, you can have three selectable operating modes: loading mode for heavy materials handling tasks, pallet mode for gentler driving and eco mode where the engine revs are capped at 1,650rpm.

The articulated chassis uses a pivoting rear axle. We have to say the articulated joint is very tidy with neat hose routing, and there is little opportunity for dirt and crop debris to collect here. The underbody is protected with steel plates.

Auto-greasing is a standard feature. The diesel and AdBlue filler necks are protected under the electrically opening bonnet.

Hydraulics and boom

The 190-litre variable displacement pump for the loading/steering hydraulics operates at 280 bar, while a priority valve ensures that the steering system always gets first dibs on oil flow.

The fill level of the 202-litre hydraulic oil tank can be easily checked through a sight glass, and all hydraulic functions can be mixed. Usefully, there is a lockable floating position for the boom.

The maximum lifting height is specified at 3.94m, but there’s an option of a long reach boom to increase this to 4.45m. Weycor only offers Z-kinematics for bucket guidance. A quick-attach headstock with Volvo couplers is an option. View of the fork was good in all positions.

Incidentally, the thorough final checks at the factory deserve a mention: Each loader is not only test-driven on the road for one hour, but also extensively worked on a test bench.

Easy to operate

Despite the comprehensive setting options, the controls are relatively easy to fathom and use. The central display also acts as the speedometer, and there is a clearly laid out keypad for altering the drive and hydraulic settings. The direction of travel, third and fourth services, diff lock and the kick-down function can be controlled from the joystick. There are simple toggle switches for further functions including quick-attach locking, lights or reversible fan.

Traction and speed limits, cruise control and a hand throttle help to increase operator comfort. A separate brake pedal is designed to prevent driving against the service brake when using the inching pedal. The tilt and height of the steering wheel, including the display, can be adjusted using a foot switch, and there is enough space next to the seat for a cool box.

In work

We used the AR680 with a 6.0m folding silage fork on the maize clamp. The powerful thrust was impressive. The easily engageable diff lock also proved to be useful. However, the inching pedal is a weakness when rolling the edges of the clamp, because the loader continued rolling on for another 50cm after pressing the pedal. This is when you need to press the separate brake pedal. Another point of criticism is the particularly vocal fan noise, which is annoying both when the cab window is open and closed.

Back to some positive news, the hydraulics enable precise operation and mixing of all functions.

Although the cab appears large from the outside, tall operators will feel somewhat cramped inside; and storage cubby holes are few and far between. All-round visibility is excellent and complemented by a reversing camera, with its screen positioned next to the rear-view mirror. Ergonomic steps and sturdy handles make it easy to get in/out.

Further adjustments

Based on last season’s experience, Weycor is planning a few tweaks to the 680 which it will present at Bauma in April. These will include improvements to the inch function, an LED light package and joystick steering … along with a few other things, too.

Sebastian Rüther

For more up-to-date farming news click here and subscribe now to profi and save.