The Walterscheid Counter can be used to keep track of operating hours and maintenance intervals on pto shafts. We fitted the small sensor to a machine to try it out.

KEEPING IT BRIEF

- A study conducted by the Technical University of Munich found that machine owners can save up to 94% of the cost of lubricant and up to 82% in labour, just by following the service and maintenance instructions.

- The Walterscheid Connected Service Assistant app can also be used without the maintenance log counter.

When it comes to diligent pto shaft maintenance there are generally two camps — its either neglected or over-indulged. The grease nipples are often difficult to reach or simply forgotten. However, regular maintenance can almost double the service life of a drive shaft, which saves money, especially when it comes to more costly wide-angle units with slip clutches.

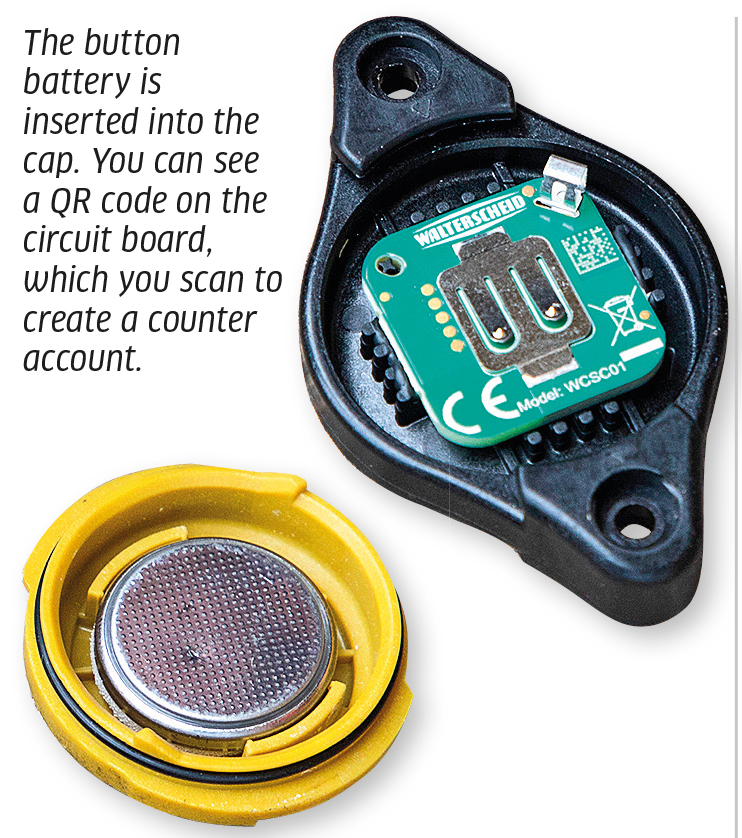

The Walterscheid Connected Service Counter uses an app that alerts the machine operator that the shaft needs greasing by counting the operating hours of the driveshaft. The novel technology consists of an acceleration sensor, which detects the vibrations of the moving machine, and a magnetic field sensor that recognises a rotating drive shaft, all in one neat little device. The data is transmitted via Bluetooth Low Energy 4.0 within a radius of up to 10 metres at max. 1mW, and the necessary power is supplied by an IEC-CR 2032 lithium battery, which, according to the maker, lasts up to 12 months.

The app

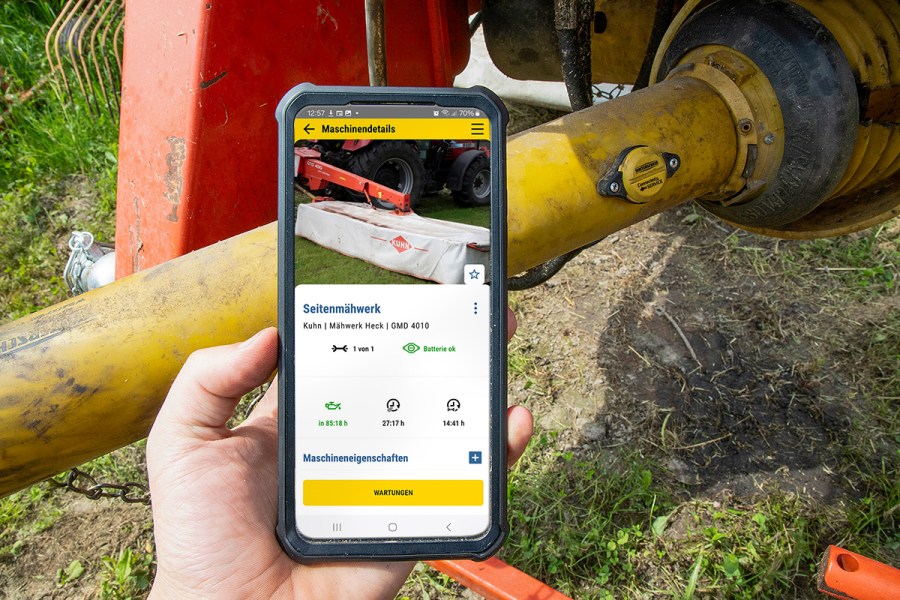

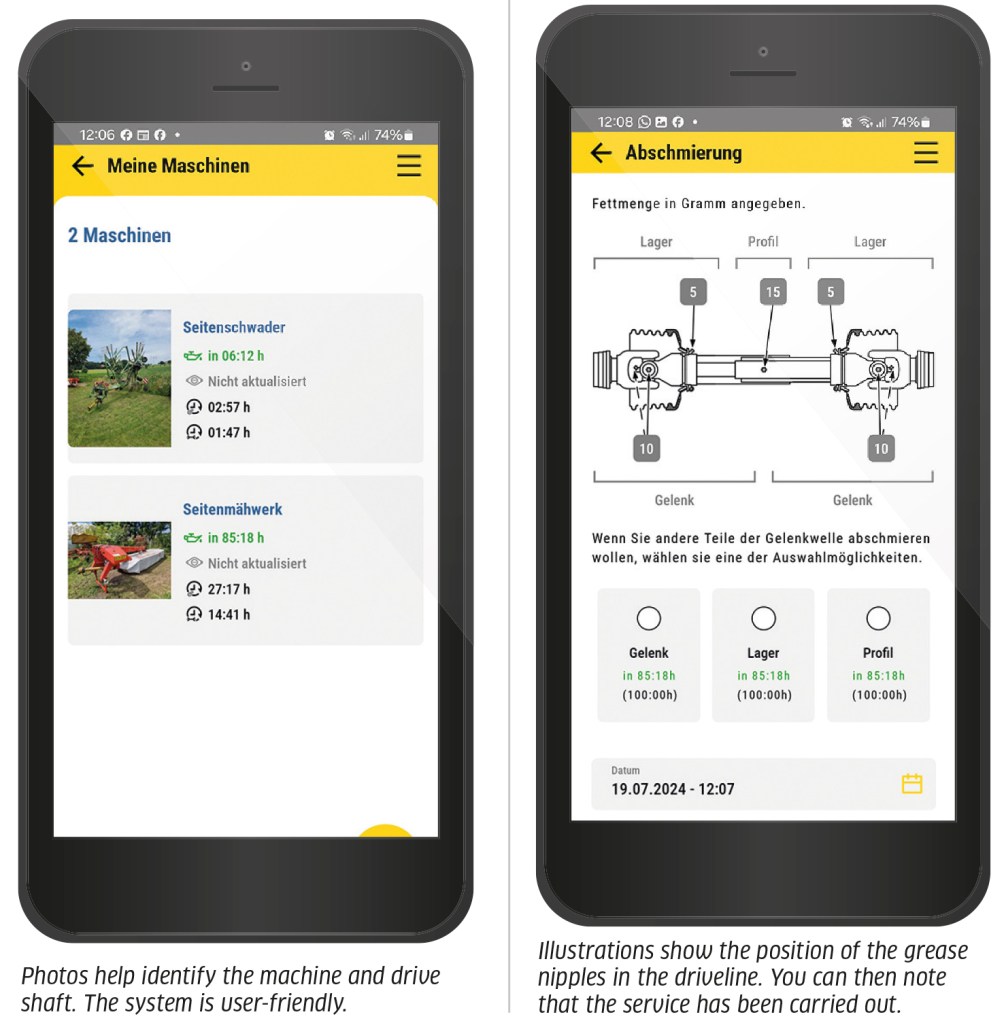

To receive the data on your smartphone, users need the free Walterscheid Connected Service Assistant app, which can be down- loaded for Android or Apple devices at www.walterscheid.app. Once you create a user account within the app, you can enter the machine, the pto shaft and the counter, which is straightforward to do.

Walterscheid’s more recent driveshafts have a QR code printed on the guard tube, which you simply scan instead of selecting the driveshaft series etc. The sensor also has a QR code that is printed on the circuit board; just twist off the cap and you can see it. If the pto shaft happens to be used on two different machines, its identifying data can also be stored on another machine profile in the app.

Likewise, it is also possible to assign several pto shafts or other components to a specific machine, and a notification is sent to the operator when it’s time to grease it. To make this easier, the app contains the standard lubrication intervals for all Walterscheid pto shafts programmed into it. There are also illustrations that indicate the grease points on the various shafts.

Once the servicing has been carried out, you then tap the appropriate button on the app which logs the date, time, and you can also include a brief comment.

Recording operating hours

In addition to the digital log book function, the app also records the number of operating hours of the implement. This makes it easier to keep track of hours when contracting or hiring a machine. App users can grant access rights either as a manager or a staff member to the app using email to ensure staff know when the machine was last serviced. You either have unrestricted access to all of the functions or view just the operating hours and log a service.

Price and first impression

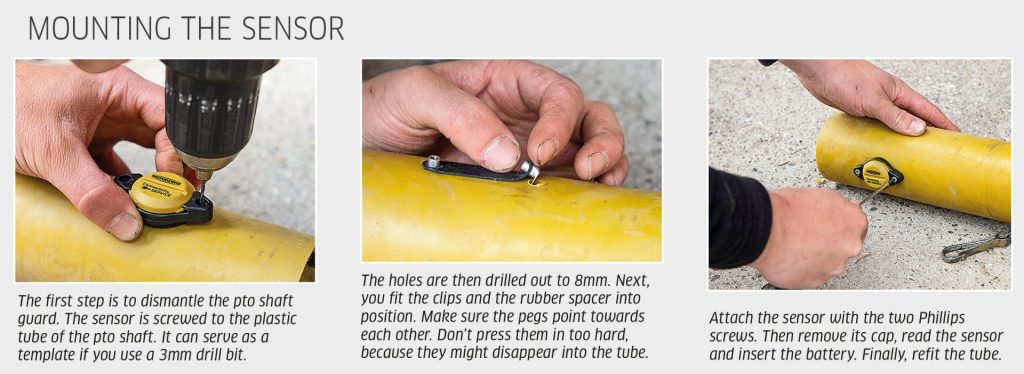

Each sensor costs about €50. The app is free to use, which keeps the overall costs within limits. The counter and the app can be helpful, especially if you’re managing a fleet. We really liked the hour counter, which we used on both a rake and a mower. The hour counter proved to be very accurate. You do need to ensure that the guard is intact and that the chain is in place to stop it turning.

Alexander Bertling

For more up-to-date farming news click here and subscribe now to profi and save.