Simulation software can show how much the type of tyre can influence how pressure propagates down into the soil. This article looks at the software that was developed by TU Dresden; next month we’ll cover the simulation software from Terranimo in Switzerland.

KEEPING IT BRIEF

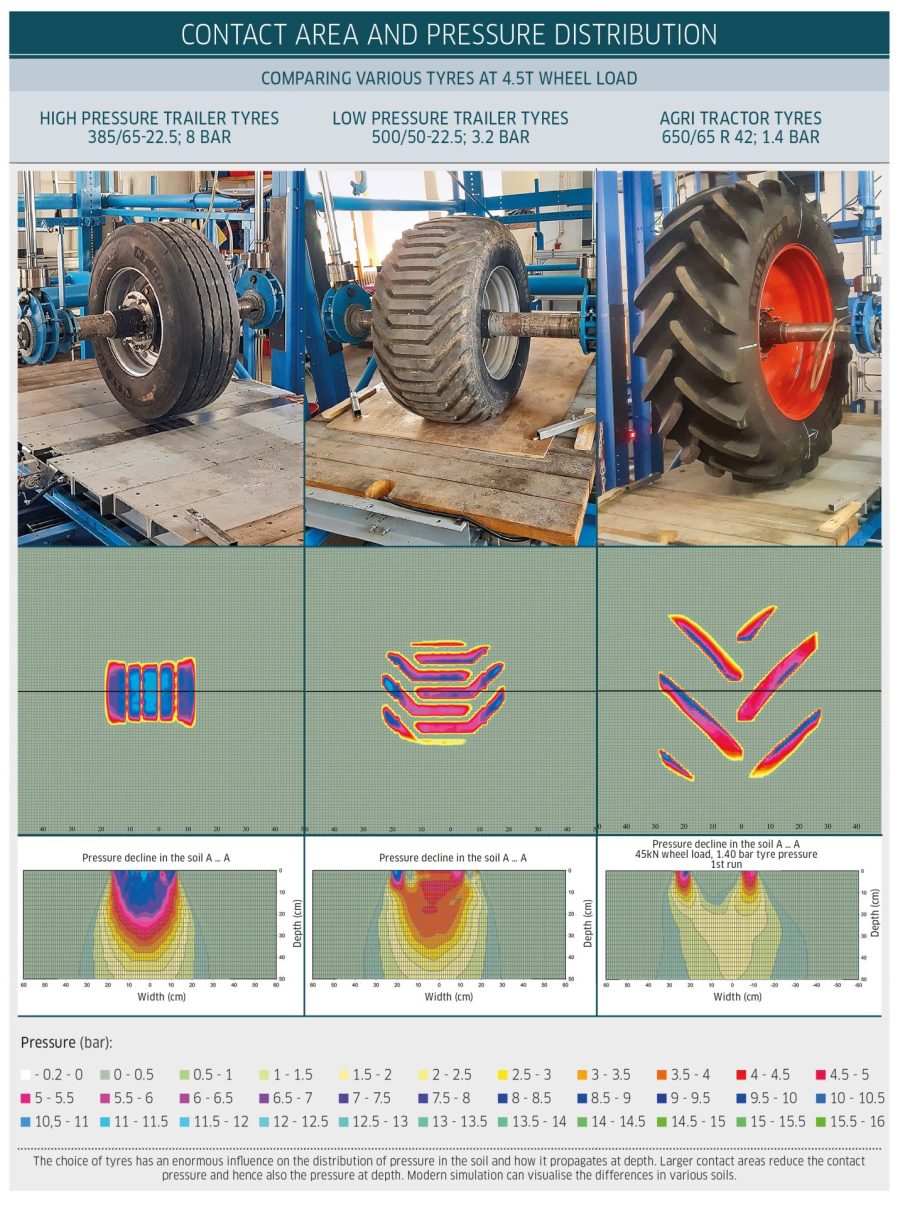

- Choosing the ‘right’ tyres has an enormous impact on how the pressure is propagated into the soil.

- Larger contact patches reduce the pressure per contact area and hence also at depth.

- Modern simulation software can visualise these effects across different soil types.

Capturing soil pressure distribution through measurement is a complex process. In addition, inserting any measurement tools into the soil may alter the soil’s condition, and results can vary significantly depending on the condition of the soil and the traffic history of the field.

For these reasons, insights and experience from hundreds of field and lab tests have been integrated into various simulation programs. Check out the ‘Two simulation programs’ panel below.

Simulation shows the difference

To show the differences among tyres, this comparison uses the software tool from the Technical University of Dresden to simulate soil compaction effects at depth. This simulation effectively reveals the potential compaction damage and its long-term impacts on soil structure.

Increased fuel consumption, due to higher rolling resistance, is just one outcome of incorrect tyre choice. Another is the risk of reduced crop yields.

For the comparison, we tested a high-pressure and a low-pressure trailer tyre as well as a tractor tyre with a suitably adjusted tyre pressure and a wheel load of 4.5t on the TU Dresden test bench. After that, the pressure at depth was then simulated and visualised.

It’s all down to tread depth

The drawback of the system, though, is that it considers a tyre’s ‘cross section’ at a single point.

Therefore, simulation results may vary significantly depending on the position the tyre was in when the measurement was made. This applies especially to ag tyres and for any measurements taken near to the surface. Apart from that, the measurements are made on paved ground where the areas between the lugs cannot be represented. However, when sinking into the soil, these inter-lug areas also contribute to the overall footprint.

TWO SIMULATION TOOLS

The model presented above was developed by the Agricultural Systems Technology department at the Technical University of Dresden, which also hosted our comprehensive tyre comparison test (profi 9/2024). Another simulation tool, Terranimo (terranimo.ch), originates from international research spearheaded by the Bern University of Applied Sciences in Switzerland.

These two models differ in their approaches. Additionally, the measurement data used to ‘parameterise’ each simulation were collected through distinct methods.

This diversity is reason enough for us to showcase the Swiss research in an upcoming issue of profi. The two research institutes also aim to increase collaboration in the future.

Hubert Wilmer

For more up-to-date farming news click here and subscribe now to profi and save.