TECHNICAL: Last year, Claas presented a semi-electric drive system for its combines. Could this really work, and exactly how does it improve efficiency? We find out a little more.

The engineering department at Claas is considering new battery-powered electric drives as a possible solution for smaller tractors and yard loaders as well as medium-sized tractors and wheel loaders. And these machines with a higher power requirement, and that possibly have to travel longer distances between the field and charging station, could also use a gas engine or hydrogen drive system.

However, developers currently see no real alternative for high-powered draft tractors, combine harvesters and forage harvesters to the combustion engine and liquid fuel. A lithium-ion battery that could provide the equivalent energy you get from 1,000 litres of diesel, would ultimately weigh 25 tonnes. Equally unfathomable is a hydrogen drive, because 1kg of hydrogen has about eight times the volume of 1kg of diesel. In addition, the storage and cooling infrastructure is complex and expensive.

Semi-electric drive

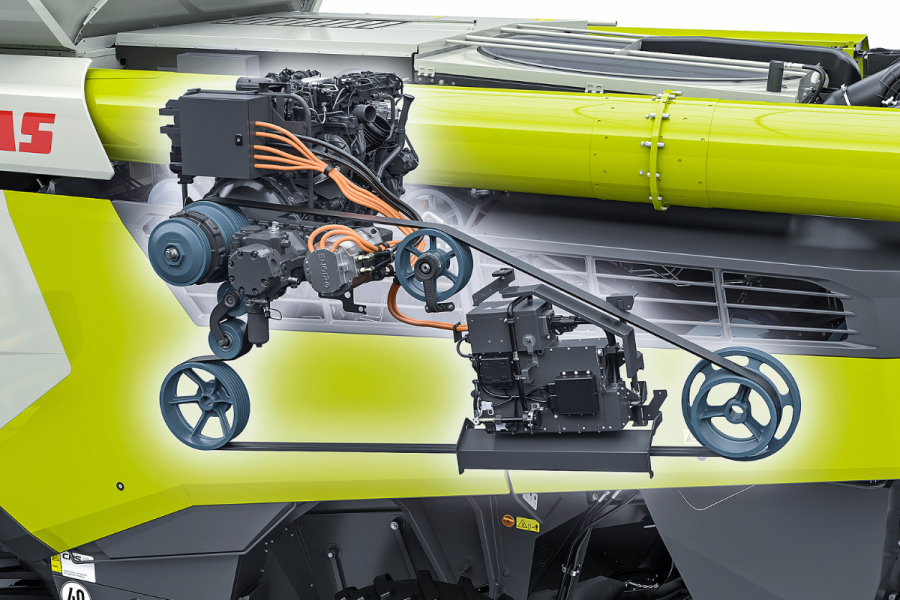

Searching for other new ways that increase the efficiency of combine harvesters, Claas developed a semi-electric drive. To do this, they added an electric motor with an output of 55kW/75hp to the 340kW/462hp diesel engine in a Lexion 7500 and installed it on the central gearbox. Together with a 48-volt inverter, this electric unit can switch between two functions in a fraction of a second — as either a motor or as an alternator, charging or discharging the on-board 2.7kWh battery. Tests by Claas show the electric motor is able to absorb temporary peak loads (< 10 secs). Also, the alternator recharges the lithium ion phosphate battery in those applications that require less input.

For more up-to-date farming news click here and subscribe now to profi and save.