Could growing more pulses and legumes help UK farming reduce its carbon footprint and become self-sufficient when it comes to animal-fed protein? This is part of the NCS study, and last year we took part in a trial looking at ways on how to most efficiently harvest the crop. Here are the findings.

KEEPING IT BRIEF

- A DEFRA-funded project, the Nitrogen Climate Smart initiative is examining ways to grow native protein sources among other things.

- Field beans harvested for wholecrop could play a big part.

- Reducing field losses and the most efficient way of harvesting the crop were parts of a trial carried out for the second year running in 2024.

- Increasing the area of legumes and pulses grown in the UK could also reduce the nation’s fertiliser usage.

Each year the UK imports around 2.4 million tonnes of soya for use as animal feed. For health reasons we wouldn’t advise delving too deeply into the maths, but scarily that equates to some £1.1bn going out of livestock farmers’ pockets each year and generally landing in South America.

So what if we could cut that figure in half? A project funded by DEFRA through Innovate UK is looking to do just that. Set up in 2022, the Nitrogen Climate Smart (NCS) initiative is looking at ways of reducing our reliance on bought-in protein and artificial fertilisers. On paper the scheme’s aim is primarily to cut farming’s carbon emissions, but in doing so it is hoped it can also help underpin UK agriculture’s bottom line.

Part of that is a programme to investigate ways of making more of home-grown crops of beans and pulses, aiding both arable growers and livestock producers in slashing their carbon footprint as well as their inputs costs. The project’s aim of increasing the area of legume crops grown from just 6.3% of the UK’s total cropped area to over 20% could have a huge impact on margins for arable farmers.

It is estimated that it will not only reduce dependence on fertilisers but also has the potential to cut fuel use by 8%. According to Farm Carbon Toolkit, currently the tasks involved in growing each hectare of cereals consume an average of 91 litres of diesel. Beans and pulses require only 84 litres/ha.

But when it comes to fertiliser reliance there is not only the reduction in applications to the cropped area but also a reduction through the rotation thanks to the residual nitrogen fixed by these leguminous crops and harboured in the soil for the following years. Pulse residues can enhance nitrogen availability for subsequent crops by 35- 70kg/N/ha, so there’s clearly the potential for some big savings when you consider Britain has 4.3million hectares of cropping.

However, it’s the potential for reductions in artificial fertiliser applications that is even more startling. According to NCS figures there was an average of 125kg/N/ha applied across the UK in 2023 putting the total at 546,266 tonnes. By expanding pulses to cover a fifth of arable cropping, it is said UK farmers could reduce their applications by a total 75,000 tonnes. With ammonium nitrate hovering around the £340/tonne mark, that’s a big chunk of wonga to be saved.

The reality

But how practical is the idea of expanding pulse acreages to a fifth of the UK’s total cropped area? Can beans be grown on a widespread scale across the UK, not just for combines to gobble up but also to be chopped and clamped as wholecrop silage?

These are some of the questions the NCS project aims to address. One of the elements of the programme is to look into ways of making bean and pulse cropping accessible to growers across the UK. Recognising that it’s not always possible to get crops in the ground pre-winter and therefore to a stage of maturity at harvest for combining, the initiative has ring-fenced a sum of money for research into the feasibility of beans as an ensiled crop to be included in ruminant rations.

As one of the industry partners involved in the NCS scheme, feed preservation and processing specialist Kelvin Cave set up on-farm pilots to look at ways of producing decent home-grown bean silage.

“Traditionally as an industry we’ve focused on starch-heavy crops for rolling/crimping,” says Michael Carpenter, technical director at Kelvin Cave.

“But if we’re to move away from imported soya we need to focus on home-grown protein. We didn’t want to reinvent the wheel. Faba beans are a well-proven crop in the UK so we decided it was sensible to focus on them as the best potential replacement for soya.

“With funding secured from Innovate UK for the NCS project, in 2023 we set up an initial trial in Lancashire to look at the best ways of harvesting/clamping beans. We already had a number of farmers whole-cropping beans but needed to put proper data in place to back-up their gut feelings,” he explains.

Kelvin Cave has some background in the inclusion of pulses in cattle rations and has worked on a number of options for green-crop silage over the past ten years. While dry-harvested beans can be rolled, tempered and crimped, combining isn’t always a reality where it’s tricky to reliably establish winter crops and cut them at full maturity. A good number of farms lack suitable storage, and an earlier harvest in some marginal growing areas makes wholecrop the most attractive option.

Often ensiled beans can also be popular when extra bulk is required, especially as an alternative to straw as a base for a high cereal diet.

One of the key objectives of the NCS project is to find ways of overcoming obstacles on-farm. Anecdotal findings from those already growing wholecrop beans suggested that in-field harvest losses were a big issue both in terms of lost yield and with volunteers in the following crop. The initial Lancashire pilot in 2023 suggested shedding at the header was the biggest source of problems.

To that end the 2024 trial would look at the impact of forager header choice on in-field losses as well as preservation of the crop in the clamp. We were privileged to be invited to participate in those harvest trials last autumn.

Field trials

Last spring 44ha of field beans were sown on a farm in Dumfriesshire with the ultimate aim of eliminating any bought-in feed for the unit’s 400-head of beef cattle. The crop established evenly and grew to a decent height suggesting the potential for good yields.

By the beginning of October the crop was still very green — not a bad thing given what ends up in the clamp should ideally be between 55-70% dry matter. One of the critical things noted from previous trials was that the crop should remain standing at harvest to avoid the risk of soil contamination in the clamp. Also, dry, stemmy beans don’t tend to consolidate well so green material is no bad thing.

While the obvious choice for harvesting any wholecrop might logically be a wholecrop header, crop losses in the 2023 pilot trial suggested that other alternatives ought to be sought. At relatively short notice we approached the usual suspects to lend us a forage harvester equipped with a choice of front-end weaponry.

Krone UK kindly came up with the goods in the form of a Big X 630 with an XDisc 620 whole-crop header, an XCollect 7.5-3 10-row maize header and a standard 3.0m EasyFlow grass pick-up. In addition, we had a Krone Big M 450 self-propelled mower in the mix to spice things up a bit.

Alongside that kit arsenal we had a local contractor’s Claas Jaguar 950 equipped with a DirectDisc whole-crop header to clear the headlands and act as a comparator.

The 10ha trial field was divided into three by initially striking out with the Krone maize header. Although not included in the trial’s clamped element, each trailer load was weighed and used to calibrate the forager’s yield recording package. Every subsequent load also went over the weighbridge.

The plan was for each plot then to be cut with a different approach. The first was a bit of an experiment employing the Big M’s grouper to create a swath of beans to be picked up with the standard grass pick-up. Just 20m into the first run it became clear that this was a no go. The SP mowers’ auger groupers proved particularly efficient in mulching and pre-chopping the bean haulm at the same time as shelling out the beans. The result was a row of mangled, rapidly browning mulch, sitting tightly on the deck. All across the soil surface, pale green beans glistened in the autumn sun — disc mowers and conditioners clearly do a very good job of threshing even the greenest crops.

But that wasn’t all. With pods growing right down low on the bean stems, an effort was made to wind down the mower beds as low as possible to ensure nothing was missed. Leaving virtually no stubble whatsoever to hold the crop off the ground, it quickly became apparent that this was not the way to go. Sometimes you’ve just got to hold your hands up and admit defeat…

The next attempt was made with the XDisc wholecrop header hitched on the nose of the Big X. Initially beans were pinging in all directions but, with the serrated paddles on the centre section of the header auger reversed, the stripping effect appeared to be under control. The forager cruised up and down nicely, seemingly feeding in crop with minimal effort.

Next up it was the turn of the XCollect maize header. With spinning sickle discs on the underside and endless collector chains drawing crop to the feed rollers, this header immediately appeared to be doing a better job of clearing the crop without shelling out the pods prematurely. With teams of people counting losses on the floor following each machine, that would soon prove to be the case.

Here comes the science bit…

With the trailers loaded, weighed and tipped up, Dr Dave Davies took over grabbing 2.5kg samples and stuffing them into glass Kilner jars to mimic the process of being packed into a silage clamp. After 90 days in the jar, they would then be analysed.

In addition smaller bagged samples were immediately put on ice ready for wet chemistry analysis in the lab, while others were mixed with water to synthesise what happens in the rumen.

Summary

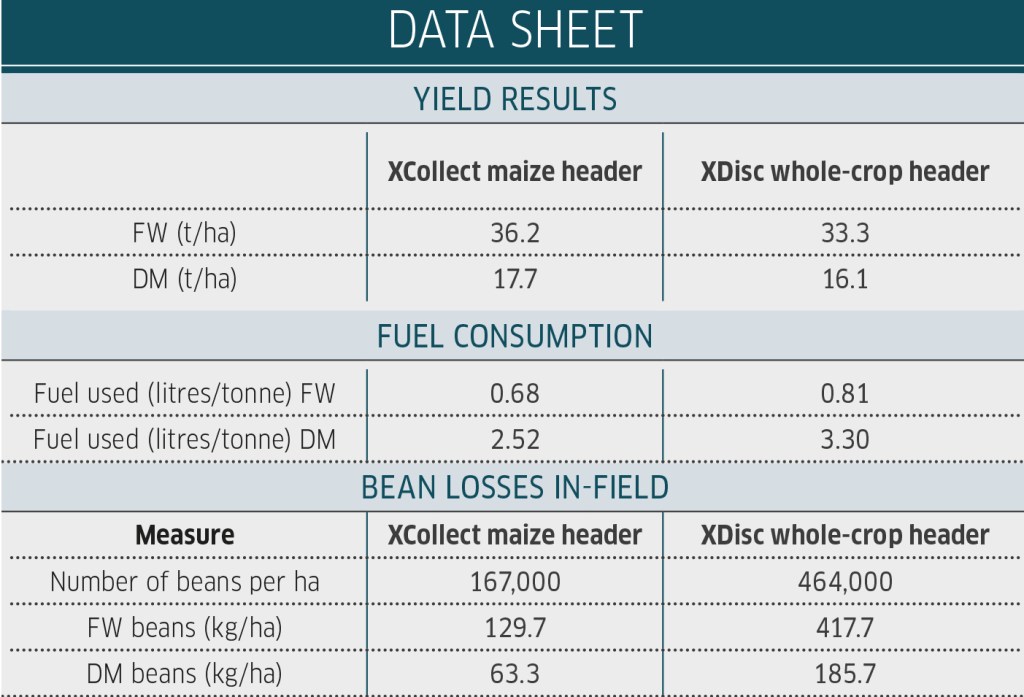

The maize header was more efficient than the whole-crop header in all respects: 14% more DM yield per ha; 24% less fuel used per tonne of dry matter harvested; losses on the ground reduced by 66%.

Krone’s on-board yield recording package was also more accurate at estimating fresh weight yield with the maize header than it was with the whole-crop header. It’s thought that this is down to the fact that crop yield measurements are made based on deflection of the feed rollers — i.e. the deeper the mat of crop, the greater the feed rollers are forced apart.

The system was calibrated with the crop cut by the XCollect maize header. Not having a cross-auger to convey crop to the feed rollers, material is not pre-compressed and broken up passing through and is therefore more bulky. Measurements made with the XDisc whole-crop header therefore under-estimate the volume of crop, material having been pre-chopped by the header’s auger. Take home message: always recalibrate any crop yield recording system when swapping headers/pick-ups, not just when changing between crops.

As to fuel use, it’s not entirely clear why the forager would be using between 20-30% more fuel with the disc-type header. The data suggests the mower bed takes more muscle to drive it than XCollect’s spinning sickle discs and gathering chains. With the maize header being 1.5m wider, parasitic power losses are spread over a greater working width, taking more crop with each run. It’s also likely that when drawing in heavy, green crops, the XDisc whole-crop header’s cross auger saps a lot of power.

The end result is pretty clear-cut — when harvesting whole-crop beans, use a row-independent maize header rather than a disc-mower-based whole-crop header. You’ll burn less diesel, lose less on the floor and ultimately end up with more in the clamp.

THANKS TO…

Dr George Fisher, the team at Krone UK, Dr David Davies and his team at Silage Solutions, Michael Carpenter, the Birkbeck family at H & K Farms and farm manager James Marshall.

For more up-to-date farming news click here and subscribe now to profi and save.