In the UK, the trailed 6.0m Köckerling Jockey drill has a strong following. Based around the company’s Allrounder cultivator, this simple tine drill is well suited to working into min-til and cultivated ground. The rigid toolbar does have one weakness, however, and that is contour following. On less level land, seed depth control can vary. Which is where the subject Ultima drills come in.

KEEPING IT BRIEF

- Versatile tine drills can direct drill or work into cultivated ground.

- Key used tip is to cost in new wearing metal.

- As with any drill, heavy trash can cause problems.

- Said to produce even crop emergence thanks to even depth control.

A bit of a spoiler from the outset. Köckerling Ultima drills will not be the easiest of used finds in the UK or Ireland for that matter. So why cover them? Simple. These drills are decent sellers on the continent, especially in the their German homeland, their ability to sow at an even sowing depths at higher speeds making them a popular design. They are versatile too as they can work from ploughed ground and min-til right through to direct into stubble. Good UK parts support can make a ‘foreign’ sourced used buy viable too, the more so as new alternatives can come with eye watering retail prices.

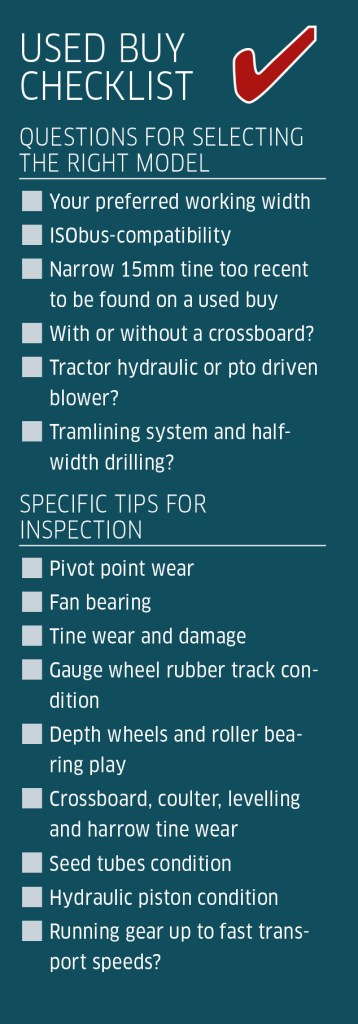

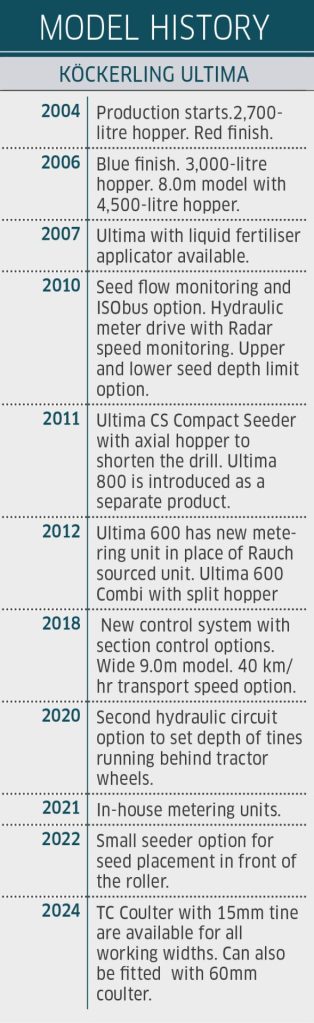

Now to the drills. Köckerling introduced the Ultima some 20 years ago as a successor to the earlier AT series. The second-generation CS Compact Seeder models arrived some seven years later, these drills having a shorter and more compact design. Common to all Ultima variants is the coulter system, each having individual gauge wheels for independent depth control. A combination of leaf springs and individual hydraulic cylinders set the drilling depth, with ability to apply coulter pressures of up to 230kg. The latter is key to the ability of these drills to work with different cultivation regimes or even go direct.

Seed is dropped behind the coulter tines, typically fitted with 60mm points, into rows consolidated by and STS roller , this comprising 530mm diameter channel-steel rings. Although tine spacing is 187mm, seed is dispersed within a 60mm band to give an effective row spacing of around 127mm. Other point sizes are available to include the more recent addition of 15mm items. These could well suit those seeking to direct drill into hard ground although ‘retrofitting’ such narrow points to an existing buy could be costly. Seek advice before taking the used buying plunge.

Generation 1 and 2

It is the second-generation CS drills that are now the more likely used find, but older first-generation Ultima drills are out there and these could prove a viable buy for those wanting to see if these drills will work for them. Features to consider on pre-CS Ultima drills built between 2004-2010 include the following:

- Working widths of 3.00m, 4.00m, 4.50m and 6.00m.

- Hopper mounted across the drill width, CS changing to lengthwise to ease filling.

- Near symmetrical four-row tine arrangement. Current CS has staggered two-row toolbar.

- Hopper loading auger was available. Not offered on current CS.

- Ground wheel driven metering unit. Hydraulic drive became an option that was then made standard on CS.

- Distributor head inside the hopper. CS models have it positioned underneath.

- No choice of attachments ahead of the toolbar. CS may be fitted with wavy discs, track eradicators or a crossboard.

Limitations and plusses

Although Ultima drills have proven versatility, the design can struggle in excess trash or coping with lodged straw in the stubble. In other words, just like other tine drills. A pass or two with a straw rake ahead of drilling is typically a good call. An Ultima plus is good depth control across the drill’s working width with consistent seed placement in varied conditions.

Basic starting point

Job one is to of course to find a suitable used candidate. If you are considering a used buy from abroad, it pays to do some extra homework. It is also worth getting in contact Köckerling’s UK importers Samagri for advice.

Initially establish the drill’s general condition and establish if there is wear in the key pivot points as this is a good pointer to past care. From 2010 onwards, the latter were fitted with conical locking pins that are less prone to wear. On the continent 3.0m and 4.0m drills are common, with 4.0m and 6.0m selling more strongly in the UK, with 8.0m variants available. The working width, incidentally, is shown by the model number; an Ultima 400 is a 4.00m unit . The 6.0m Ultima 600 is offered with a Combi split hopper for seed and fertiliser.

Getting down to details

The pneumatic fan can be driven from the tractor’s hydraulics or via a pto driven pump. The latter was more common, but modern tractor hydraulics are typically well up to powering the fan with the result this system is now more common. If a fan drive pump is fitted, ensure it is securely mounted between the headstock in work. If the chain securing it to the pto shaft fails, the pump will be at best damaged or more typically destroyed.

Both 540rpm and 1,000rpm pumps can be fitted, the latter offering the extra ‘blow’ needed for high seed rates and are the most common find on 4.0m and 6.0m models but check. The blower’s suction or pressure filters can be overlooked, a point to note if the drill needs working upon.

Hydraulic metering units on CS drills is powered by the same oil flow as the blower, so it follows that fan needs to be running for calibration. Electric drive is not available.

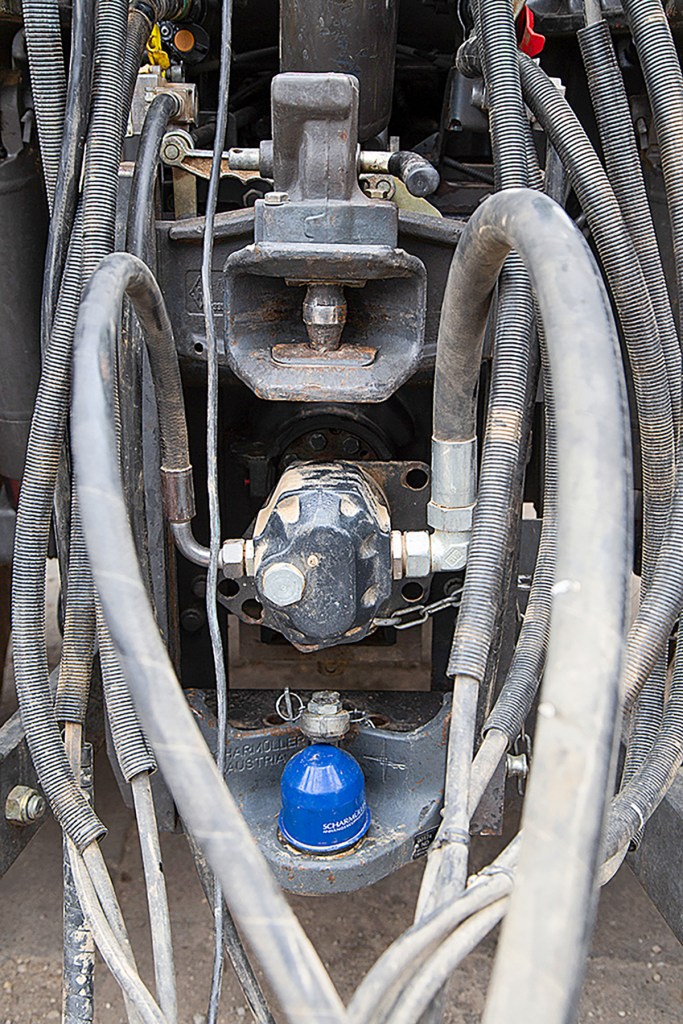

Hydraulics for the folding mechanism, levelling crossboard or markers are operated through separate single-acting or double-acting spools. Prior to 2007, all drills were fitted with Rauch controllers, Köckerling offering an ISObus-compatible WTK control system from 2009. Rauch continue to supply the fan and the hopper, with most metering units also sourced from Rauch until 2021. So do not assume a drill will be ISObus or variable seed rate ready.

From 2022, Müller-Elektronik control software was introduced and offers features to include half-side shut-off and full Section Control for individual rows. Models from 2009 may be upgraded to the current software version but this will require a new wiring harness, and possibly an ISObus terminal, the distribution head will need shut-off flaps for section control. An upgrade is, in other words, likely to be expensive. Again, seek advice.

Pay Attention to the metal

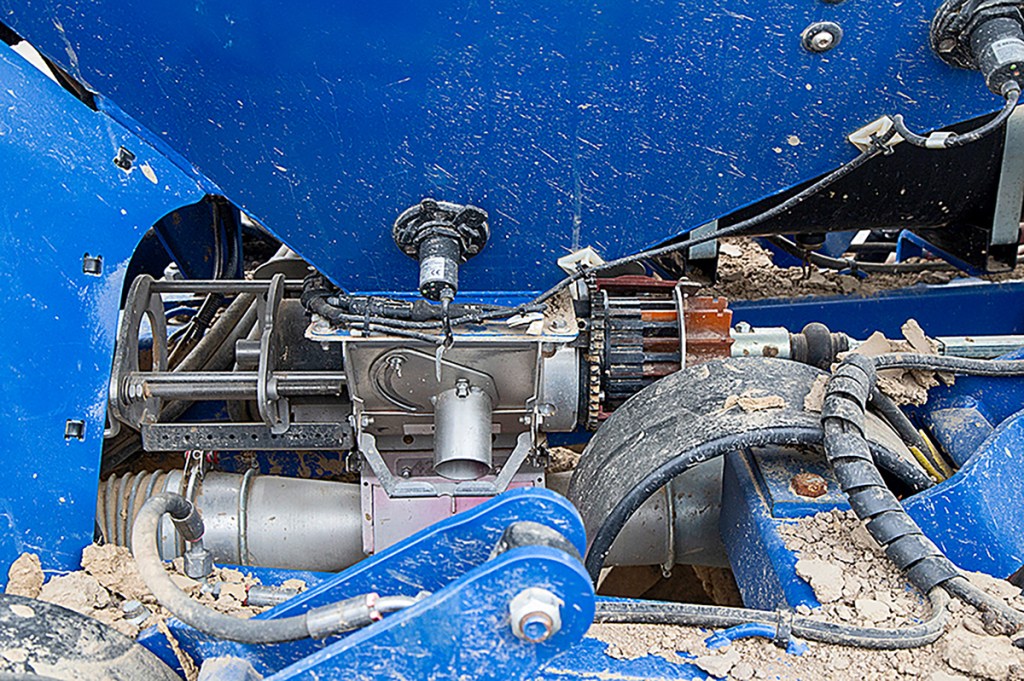

These trailed drills can be turned tightly on the headland, with the later CS version benefitting from its more compact design. This can mean the telescopic drawbar gets clobbered in too tight a turn so ensure it is in good shape at full extension, checking for damage and weld repairs. The lower link couplers and bushed pivots are wearing points. Easy to overlook.

Inspect the Individual Rows

Next, we look over each tine row in turn. Key wear or damage points to consider are the springs, hydraulic cylinders, the coulters and the gauge wheels rubber tread. If the hydraulic cylinders need to be replaced, these list at €226 each. The 500mm by 180mm depth wheels typically last well, but their rubber tracks are wearing items that cost €179 apiece. A point to note is renewing these treads is eased by the depth wheels having a two-part wheel construction.

Depth wheel bearing wear can be detected buy listening out for noises as a wheel is turned and checking for play. These items are long lived but if you find one has failed check the others. Renewing the bearings is not difficult, but you will need a puller to remove them from the stub axle.

Wearing parts

With luck, worn reversible coulters may be flipped around to fresh metal or be refitted in a different position to optimise their working life. Always take a good look at the tine leg itself as the hydraulic depth control system enables the holder to be lowered so it will touch the ground and so be subject to wear too. The levelling tines are fitted with replaceable wear plates. The harrow tines holders can be repositioned under the box section to extend their service life, a point to note if this has already been done.

The STS trailing roller operates as a single item and unlike on the firm’s cultivators it is not used for providing depth control. This means its weight is used for consolidation and not supporting the drill. It is possible to use these drills as just a cultivator, incidentally, with some on the continent using them to prepare ground ahead of drilling maize or sugar beet.

Inside the hopper

The hopper holds 2,800-litres on 3.0m and 4.0m models and 3,300-litres for the wider working widths. All will have two fill-level sensors with a low-level alarm inside the metering unit.

Both Rauch and Köckerling metering units are of a cell-wheel design, a manual spindle adjusting the opening aperture to suit different seed types. When switching between ‘standard’ and fine seed, the Rauch system has two lock bars to alter the setting. With the Köckerling, internal screws are adjusted to do the same job.

The polyurethane rotors on any drill do not like being stored with seed remaining in the hopper as it makes them more liable to rodent damage. Typically, not a problem area but still check everything and ensure all the cell wheels you may need for different crops are provided. The roll-up tarp covering the hopper should be in good shape and seal well.

All the seed tubes are subject to normal wear and may become perforated or brittle over time. You need to check all of them. Replacing these tubes isn’t particularly expensive but it can take time so factor this in if you need the drill in a hurry.

Other details:

- Users suggest access to the distributor head under the hopper of CS models is not the best but manageable.

- On earlier CS models, the working speed is accessed via a GPS signal.

- Start and stop the blower fan slowly to help detect any audible bearing wear.

- A 4.0m drill will need a tractor of 200hp plus.

- Check running gear tyres and look for sidewall damage.

- Popular options include stabilising discs for slope operation, bout markers, seed flow monitoring, and tramline markers.

- Müller control electronics do not have a sensor check on the terminal. This was possible with the previous WTK system, but check.

- For road transport, hopper capacity should be reduced to no more than half full and preferably empty.

- From 2020 the tines running in tractor wheel tracks can pressurised separately.

- Machines used in stony regions will need extra checks to include paying close attention to the hydraulic hoses and harnesses.

Summary

Ultima drill users tend to hang on to their machines, swapping them out only when they want upgrade to a larger working width or as part of a regular replacement cycle. Overall, these machines are considered robust and economical to maintain, with maintenance demands restricted mainly to renewing wearing parts. The hydraulic cylinder seals may fail, but otherwise there should be little to go wrong and cause concern on a used buy. As these drills are based on a relatively robust tined cultivator, they can be used across most cultivation regimes.

With additional thanks to Nigel Long, Samagri.

Sönke Schulz, James de Havilland

For more up-to-date farming news click here and subscribe now to profi and save.