John Deere’s 9RX has made its way to European fields, where we had the chance to drive the top model, the 9RX830. Will it find a home on this side of the Atlantic?

KEEPING IT BRIEF

- The 9RX710 (781hp max) and 9RX830 (913hp max) have identical hardware.

- Only available with a powershift transmission, and only offered with tracks.

- The base model carries a price tag in the region of £870k.

With the launch of the new 9RX, John Deere has undoubtedly made quite a splash. The big tracked tractor has not only been redesigned from scratch, but it also pushes the limits of performance. Until now, the 9RX640 (with a maximum output of 691hp) was the largest tractor to come out of Waterloo for many years. However, the new 9RX830 brings an extra 222hp to the power party — a colossal leap!

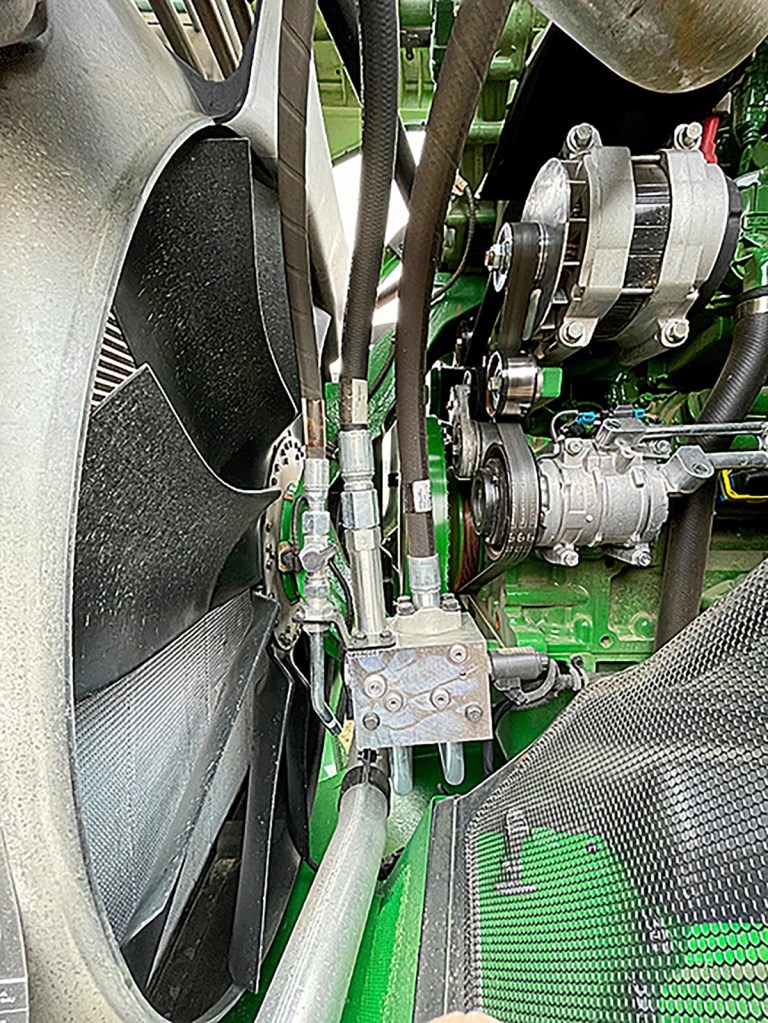

The fact that all of this power needs space becomes clear when you stand in front of the enormous bonnet. To our surprise, it can be opened quite comfortably compared to the bonnet of the well-known ‘old’ 9RX. The easy-to-access radiators are then exposed, but you probably won’t have to clean them very often, because the new Deere has a hydraulically driven fan that can optionally blow out the radiators, too … by changing the direction it rotates.

Service and maintenance are deliberately simple. All service points on the 9RX can be checked from the ground, and there are sight gauges for inspecting the coolant, fuel, transmission and hydraulic oil levels. The engine air filter can also be reached from the ground, and the engine oil can be checked via a dipstick behind a flap.

While the engine needs attending every 500 hours, the hydraulic oil only needs changing every 4,000 hours. The separate transmission oil drop is carried out every 2,000 hours.

4,234Nm torque, 2,000-litre fuel-tank

Back to the monster motor. Behind the radiator pack resides John Deere’s inhouse-developed JD18 unit — a six-cylinder engine with a capacity of 18 litres that’s already used in the 9000 series foragers.

The powerhouse is rated up at 830hp at 1,900rpm, and this then climbs to a maximum output of 913hp at 1,700 revs. And the engine delivers its highest torque, a massive 4,234Nm, to the crankshaft at 1,400rpm. This is a new level of power.

Yet this level of performance also asks for an appropriate supply of diesel. To make sure the titan won’t run thirsty, it can store 2,000 litres in its tank, which is positioned centrally under the cab and no longer at the rear for better weight distribution. However, in markets where you’re not allowed to carry this volume of fuel on public roads without a dangerous goods certificate, there’s a riser pipe in the tank nozzle that limits capacity to 1,500 litres.

On the positive side, there is no AdBlue and no DPF (there is just cooled exhaust gas recirculation), due to exhaust emission rules being less strict above 560kW/760hp.

Manual gearbox, 636l/min oil flow

John Deere has designed a completely new 21/11 powershift box for its new flagship. In terms of construction, this has less to do with the 18/6 in the well-known 9R than with the E23 from the 8R. Here, too, there are various shifting modes and a top speed of 40km/hr. There’s also an optional pto shaft that can transmit around 250kW/335hp to the likes of a chaser bin.

Rear lift arms are not available for the 9RX, not even as an option. To deal with the extra pulling power, the floating drawbar at the rear is larger. The drawbar pin on the Cat. V measures 70mm in diameter. So, pulling is not an issue. More on that in a moment.

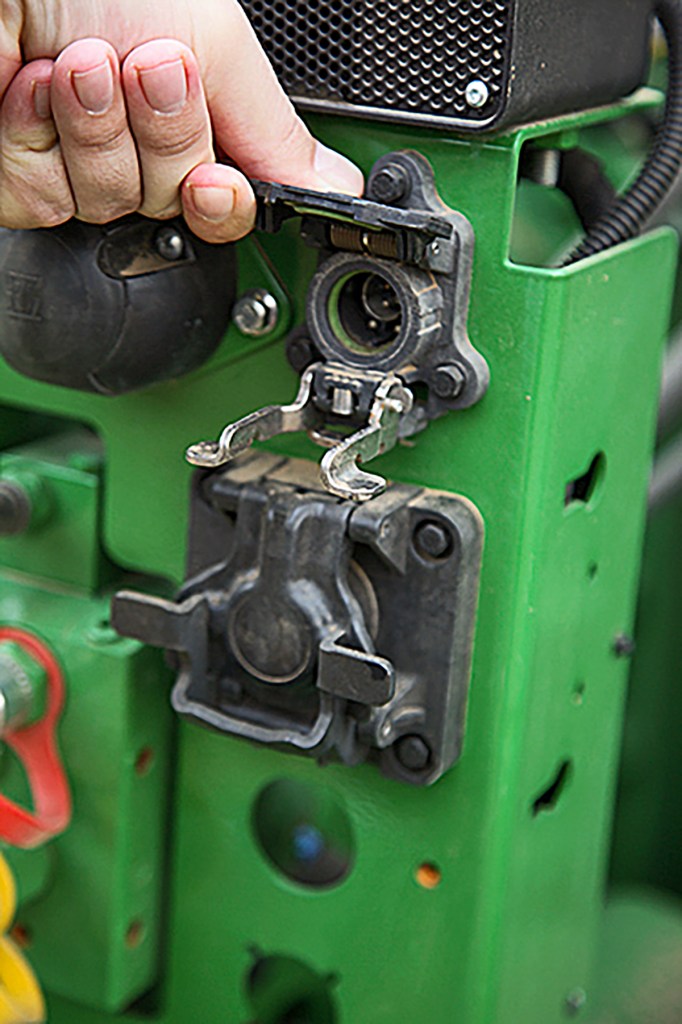

First up, let’s take a look at the hydraulics. The standard axial piston pump has a flow rate of 212l/min, with up to three pumps (total flow rate of 636l/min) as an option. This will then supply up to six double-acting spool valves and two separate load-sensing systems. It’s no surprise that you can order an optional 40hp hydraulic boost!

Larger tracks

The main task of these bigger 9RX models will be pulling huge kit. In order to put all the power on the ground, John Deere has designed larger tracks. The drive wheel has a diameter of 1.20m (1.00m on the smaller-frame 9RX) with a wrap angle of 110°, ensuring positive drive on the 76cm wide tracks. This allows the 9RX to sit bang on 3.0m wide with a track width of 2.24m.

John Deere states an unladen weight of 32.8 tonnes. Ballasted at the front and rear, we were on the road with an operating weight of more than 35.5 tonnes. Pulling a 9.0m wide Köckerling Vector, the 9RX830 gave a taste of just what it’s capable of. On the flat field the articulated tractor reached up to 12km/hr cultivating more than 30cm deep. This translates into a work rate of almost 11ha/hr! This also puts the fuel consumption of 165l/hr into perspective: 15 litres/ha is actually OK for this type of work. At this 12km/hr speed, the tractor had no problem with converting the more than 900hp into tractive power with less than 3% wheel slip.

This becomes more exciting at less than 10km/hr when traction is so high that the wheel slip quickly rises to over 6%. The max ‘fighting weight’ of up to 42.2 tonnes would help a little here. But depending on the soil conditions, the limits of physics are reached sooner or later.

Fully suspended cab, ISObus of tomorrow

John Deere is clearly trying to push the old boundaries of cab physics a little with the 9RX cab. Not only has it a 20% larger glass surface, almost all of the entire right-hand console has now disappeared. Floor space has also increased by another 15%.

In addition, there is a specially developed four-point cab suspension with an insulated subframe, which is designed to protect the driver from the vibrations of the unsprung running gear. The desired effect was still to be achieved on our pre-production machine, but it should improve on full production tractors, as will the transmission once the final tweaks have been made to its software.At the moment, the box still likes to switch back and forth several times in automatic mode when the load changes.

As far as the armrest, the G5 Plus terminals and the steering system, etc. are concerned, there is already nothing more to complain about. A new ‘Implement Ethernet’ is also making its debut, which is, in effect, the next generation of ISObus. Instead of a data transfer rate of just 150kB per second, John Deere says that the new system can handle 1GB/sec.

Summary

With the big 9RX, John Deere is opening the door to a new dimension of performance — almost 1,000hp and over 4,200Nm are huge stats. Yet it does beg the question of who needs this amount of power.

Deere must see some potential in Europe; otherwise why do all of the engineering to make sure it sits below 3.00m wide for road travel? No doubt there will be some farms in the UK that will want the bragging rights to having this powerhouse working across their land.

Hubert Wilmer

For more up-to-date farming news click here and subscribe now to profi and save.