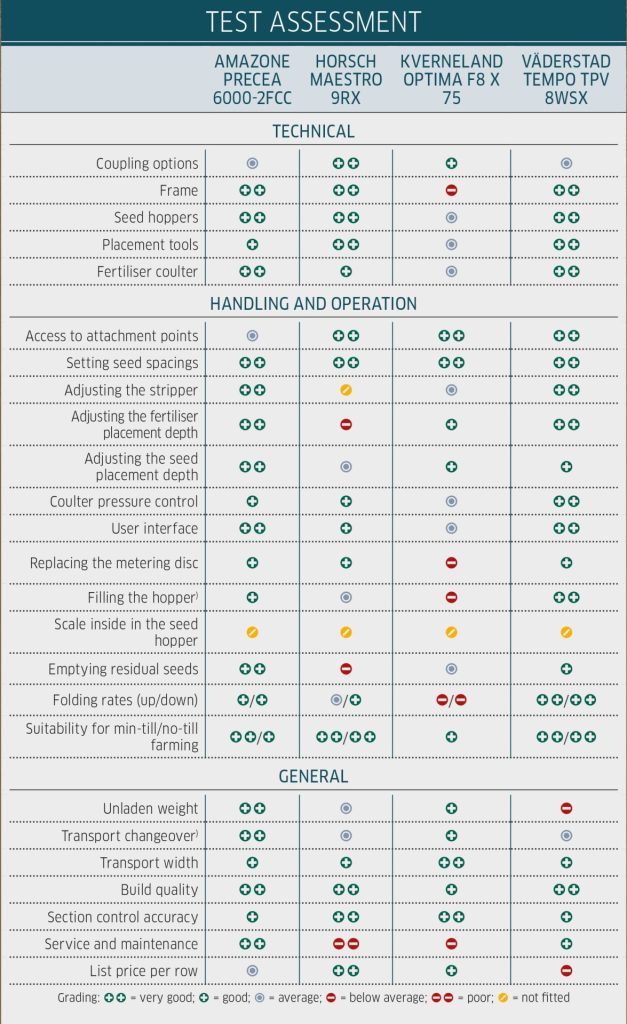

Following on from last month’s front hopper and fertiliser accuracy test, here our attention is on the planters as we assess their seed singling and placement accuracy along with their technical differences and any special features. The contenders are from Amazone, Horsch, Kverneland and Väderstad.

KEEPING IT BRIEF

- Horsch excelled in many parts of the lab and field tests.

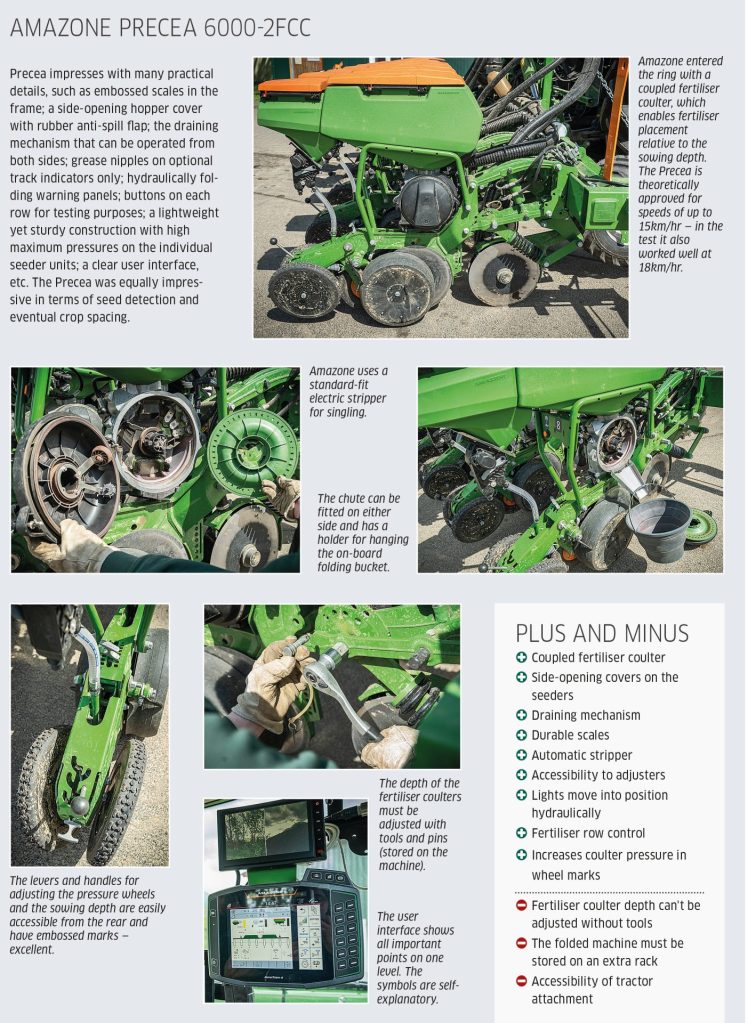

- Amazone has some good ideas for operator comfort.

- The Väderstad is the most expensive, but is a good and very robust

machine. - Kverneland struggled in the test conditions, but the price is attractive.

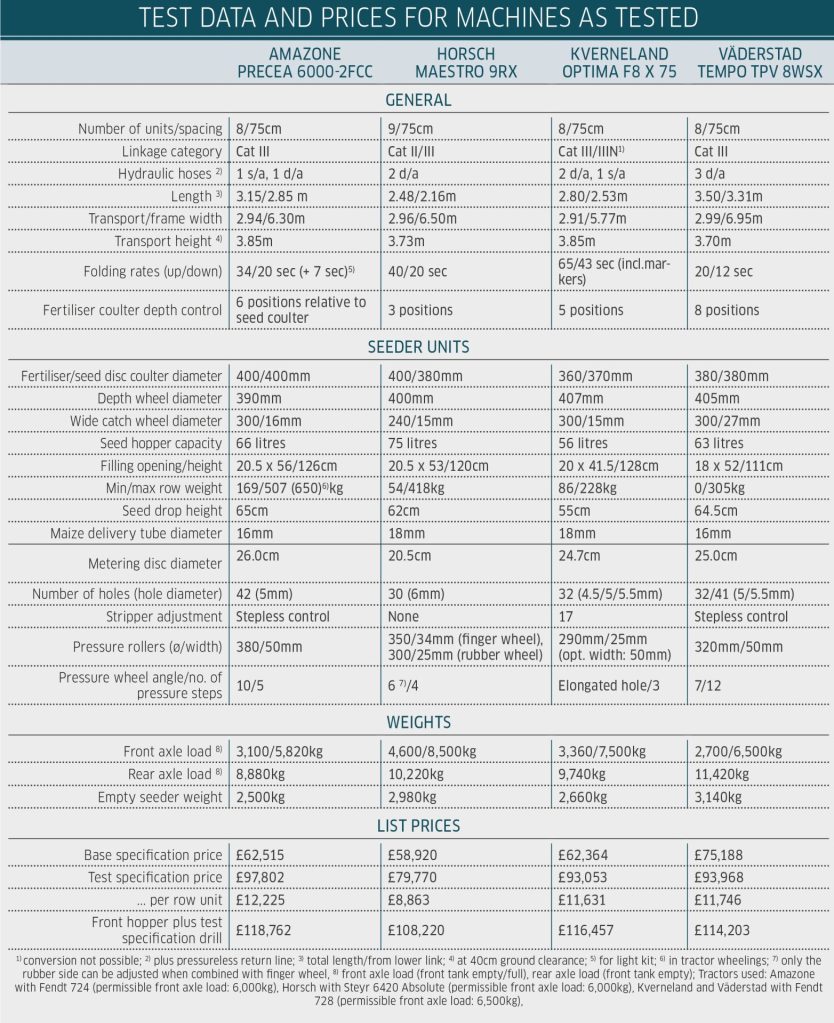

Firstly, a few technical differences between the Precea 6000-2FCC (Amazone), Maestro 9RX (Horsch), Optima F8 X 75 (Kverneland) and TPV 8WSX (Väderstad). Kverneland, for example, is the only one here to use parallel folding, so the seeder units remain horizontal when in their transport position; the other three machines fold vertically.

This has pros and cons, as the Optima never has any seeds stuck in the hopper lids and it can be stored in its folded position — without the need for a separate frame as with Amazone. But the frame designs of the Maestro, Precea and Tempo are better suited to different row widths — Amazone and Väderstad, for instance, also offer nine-row models with 75cm row widths, just like the Horsch submitted for this comparison test.

The transport dimensions are comparable. With 40cm of ground clearance, all sit well under the key height of 4.0m. There is a bit more to talk about when it comes to length and axle loads — measured while hooked to the tractors that were brought along: Horsch (without micro-granule hoppers) measures 2.16m and Väderstad 3.31m. Kverneland (2.53m) and Amazone (2.85m) occupy a middle ground position. With empty hopper weights from 2.5 tonnes (Amazone) to 3.14 tonnes (Väderstad), the rear axle load was 8.8 to 11.4 tonnes with an empty front hopper. The Precea mounts closest to the tractor, which is good for load distribution but bad for accessibility when hitching on/off.

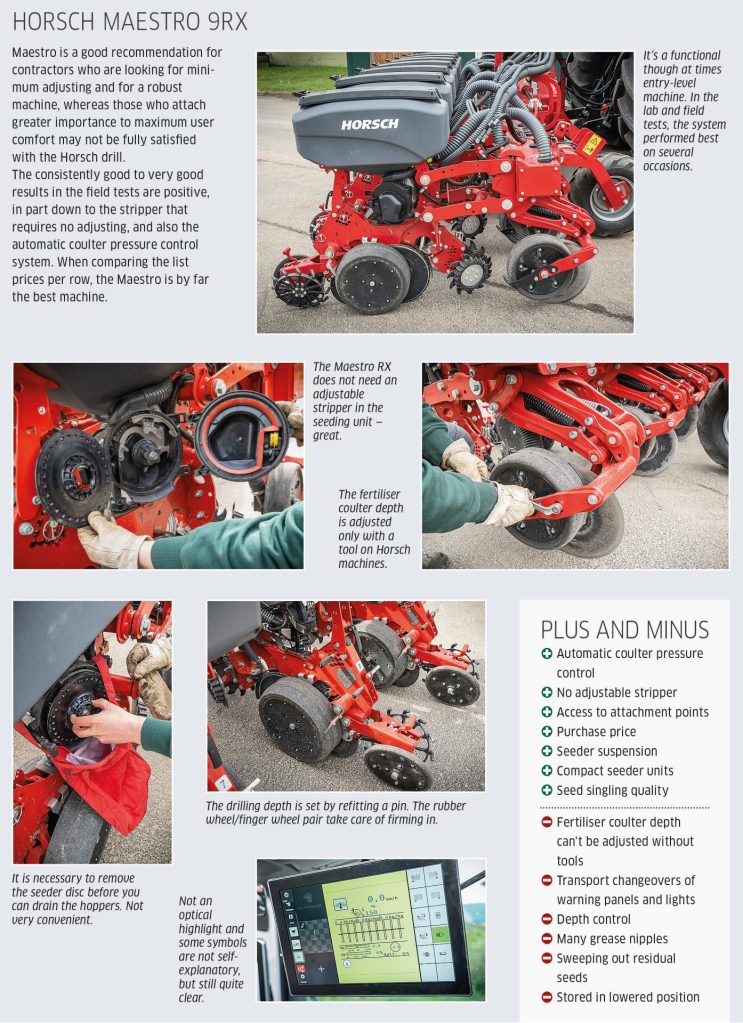

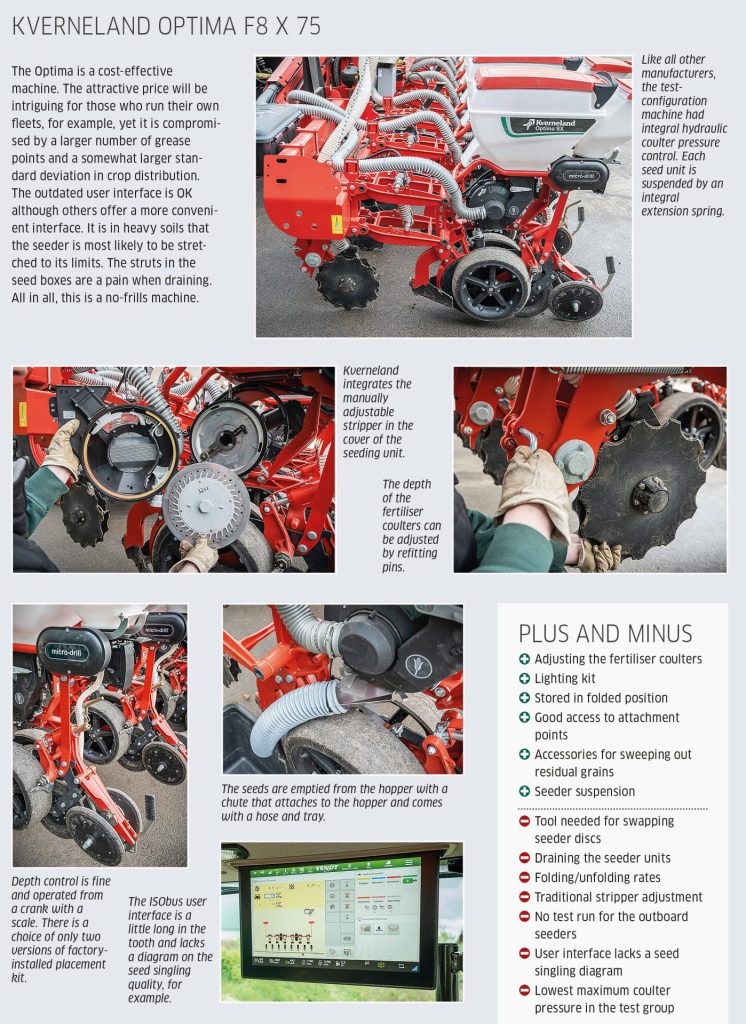

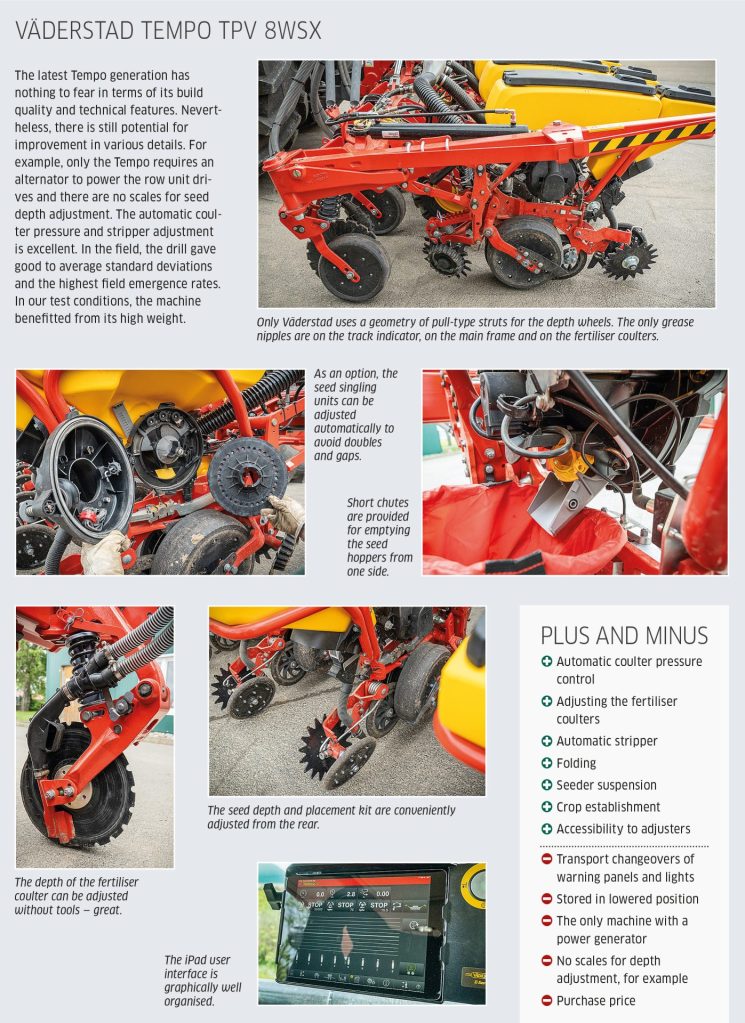

The individual row units and sowing elements share a similar design ethos: maintenance-free parallelograms, double disc coulters with a pair of catch wheels and depth control wheels followed by the placement kit. Seeds are pressed against the electrically driven rotating cell wheel with overpressure, and strippers prevent any doubles and misses. Both Amazone and Väderstad adjust these automatically (depending on the level of specification). Horsch doesn’t need adjustable strippers; Kverneland adjusts them by hand.

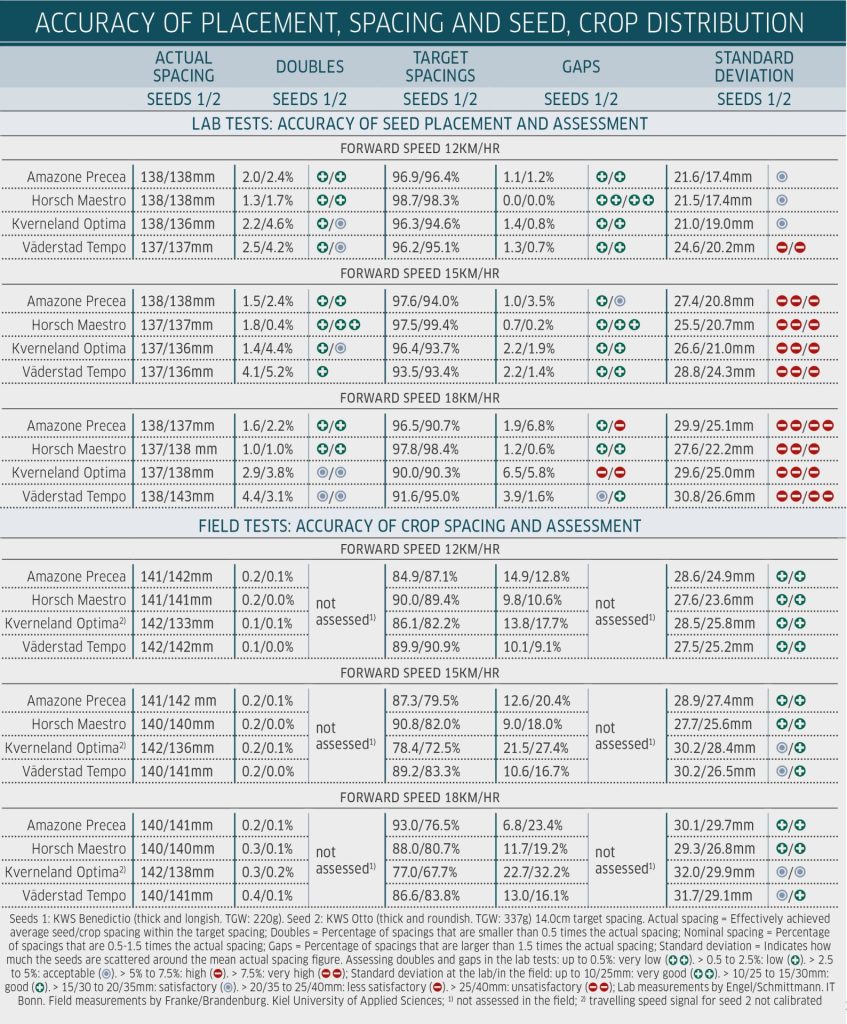

Lab test results…

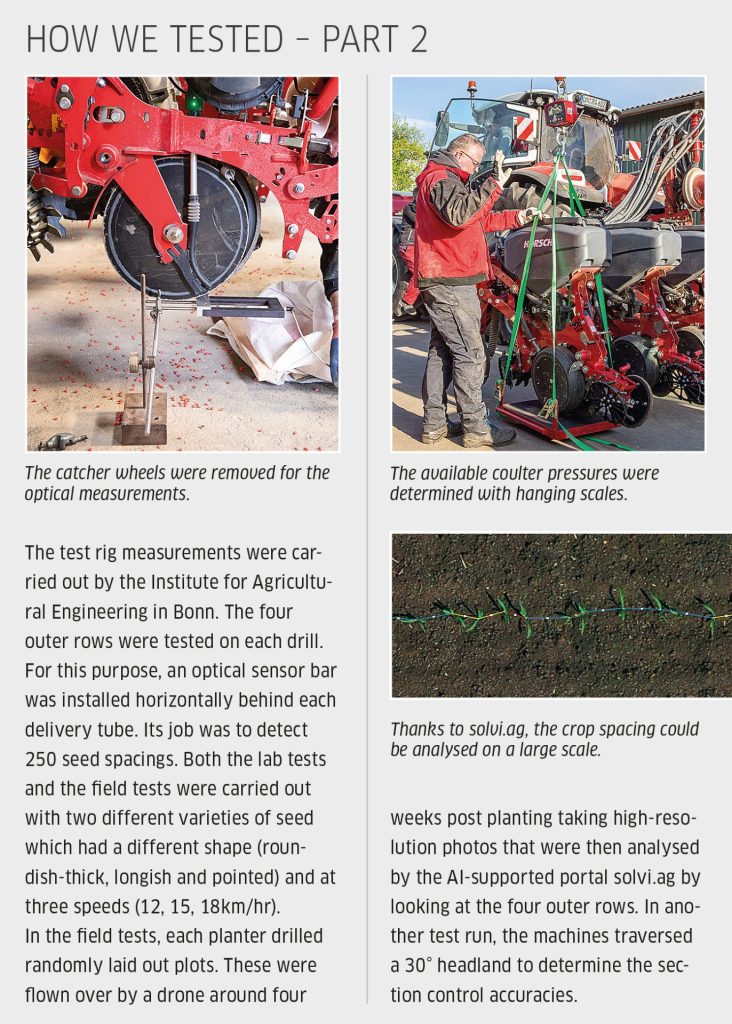

In terms of misses and doubles, Horsch delivered the best results in the lab at all three ground speeds and for the two types of seeds drilled, though seed metering tended to be more accurate for the lighter type of seed. At 12 and 15km/hr, all four makes often produced similar results, while at 18km/hr Horsch stood out positively and Kverneland negatively.

When analysing the standard deviation (seed spacing scattered around the mean actual spacing) and evaluating it using the DLG test framework, we notice the strikingly large scatter. In particular, the trajectory or drop-off point from the delivery tubes varies to a significant extent.

…then out to the field

Following the lab measurements, we wanted to see how the machines would perform in the field. To put it into perspective, the test field proved challenging due to the wet spring — ploughing and then a power harrow pass and two runs of a spring tine cultivator still saw the drills struggling with a rough surface, dry topsoil and stiff clay in the heavy clayey loam test plot.

There was no issue with doubles, which we classed as a seed spacing smaller than the 50% of the actual spacing, in the field test. Yet misses, seeds that were either not drilled or failed to emerge, were a problem: 9.1% (Väderstad) to 17.7% (Kverneland) of the plants were missing at 12km/hr. At 15km/hr, the level was between 9% (Horsch) and 27.4% (Kverneland). And at 18km/hr, the gap ranged from 6.8% (Amazone) to 32.2% (KV).

The reasons for Kverneland’s much higher percentage of missed seeds may be down to several factors: perhaps the coulter pressure was not high enough despite our machine having the handy weight transfer system that presses against the underside of the tractor’s lift arms (this feature is also available on the Amazone machines); or perhaps the frame ballasting was not set correctly.

The higher the ground speed, the greater the standard deviation in the field. Amazone and Horsch achieved good to very good results. Kverneland and Väderstad achieved good results at 12km/hr, and good to average results at 15km/hr and 18km/hr.

Speed demands coulter pressure

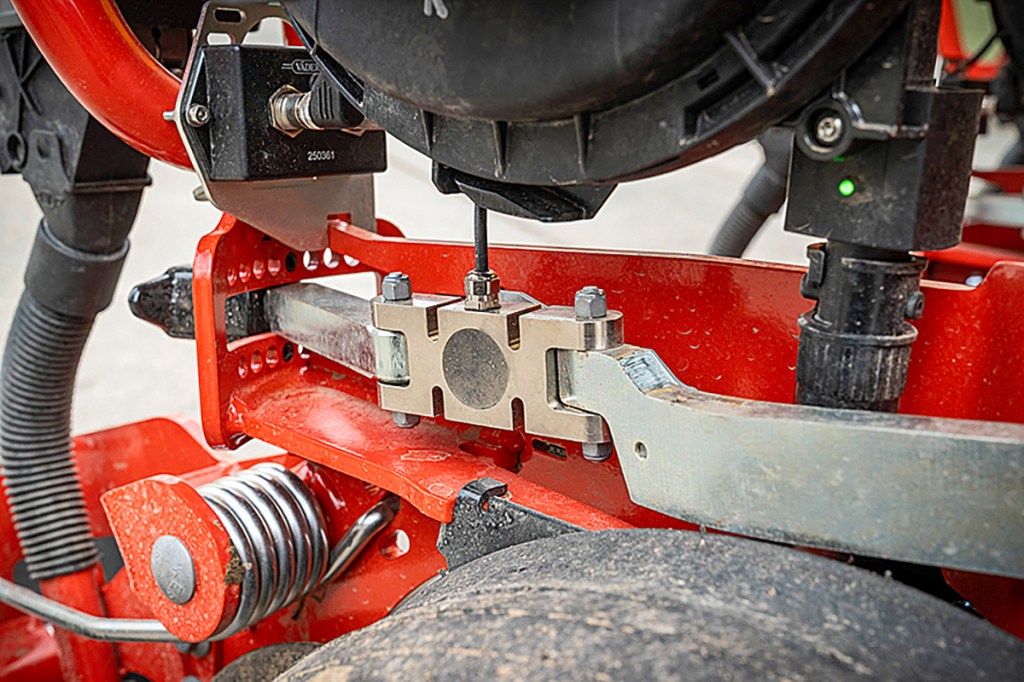

All of our machines were equipped with hydraulically adjustable coulter pressure; in fact Amazone, Horsch and Väderstad even had an automatic coulter pressure system fitted. The Precea and Maestro measure the contact force on two depth control wheels and then derive the coulter pressure for all of the seeder units from these results.

Väderstad has the option of controlling the coulter pressure individually on each row unit, which is particularly useful for drilling in wheel marks. Kverneland tells us that it too will be offering a similar system in the future.

Amazone applies more pressure to the rows behind the tractor wheels, although it needs a second service for this feature. However, it is necessary to consider the machine weight and how much weight is transferred from the tractor. Horsch and Kverneland can reduce the weight on the rows to 54kg and 86kg; Väderstad can reduce the load to the point that the unit loses contact with the ground.

56-75-litre seed hoppers

All four came with the largest available seed hoppers. Although the Kverneland hopper is the smallest, the filling height is the highest. We liked the lid on the Amazone hopper, which opens to the side and is therefore easier to access from the rear. A chute for easier emptying left-over seed is stowed in one of the lids, which is very practical. Kverneland also provides a chute for emptying each hopper from one side. And on the Väderstad seed hoppers a chute folds out to one side. Horsch opts for integrated mini chutes that empty into collection bags, but these are the least convenient to use.

Convenient setting options

On the Precea and Tempo, the seed depth can be set more easily with their spring-loaded stops and hole pattens than the Maestro solution of a pin and split pin. However, at least Horsch marks the holes with laser-cut plate. Kverneland uses a crank with a scale. On the subject of scales, Väderstad relies on you counting the holes to adjust the depth, but Amazone uses durable embossed marks everywhere — exemplary!

For fertiliser placement, both Amazone and Kverneland use double disc coulters, while Horsch and Väderstad use single disc coulters. The best depth control for the coulters comes from Väderstad with a tool-free eccentric adjuster. On the Kverneland you have to refit a pin and secure it with a lynch pin; on the Horsch you refit the bolt to one of three positions.

The Amazone test drill had the optional coupled coulter, which maintains fertiliser placement depth relative to the seed depth. The distance between seed and fertiliser is adjusted using a ratchet with a locking pin. Fertiliser coulter pressure cannot be adjusted on the Amazone and Kverneland machines, whereas on the Horsch you refit springs and Väderstad by picking a different hole from the multiple options.

Other details

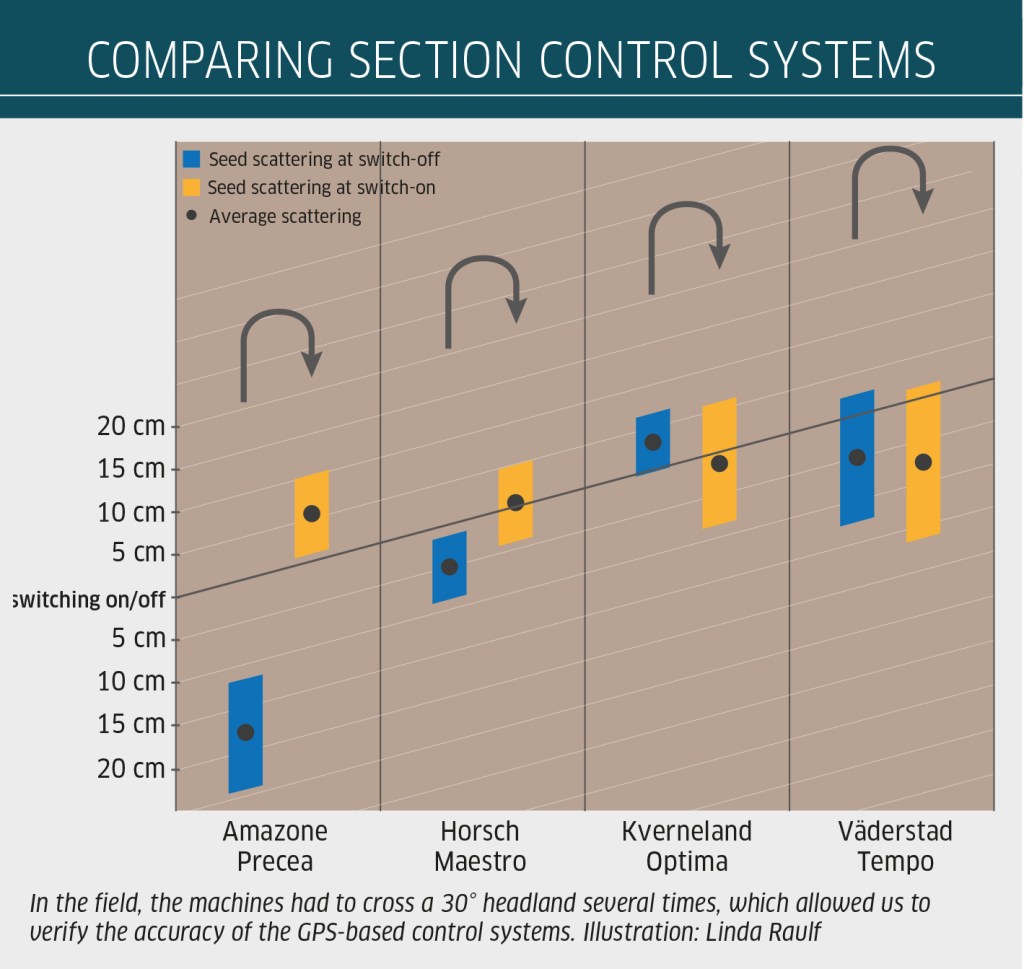

- In the section control comparison Horsch and Kverneland were the more precise of the machines on test.

- In the field test, we liked the rubber/steel firming rollers from Horsch and Väderstad.

- Horsch has 40 grease points that require daily attention, Kverneland only four and about 40 with weekly intervals. Amazone has only two grease nipples on the optional markers (every 50 hours); Väderstad has 18 (150 to 200 hours).

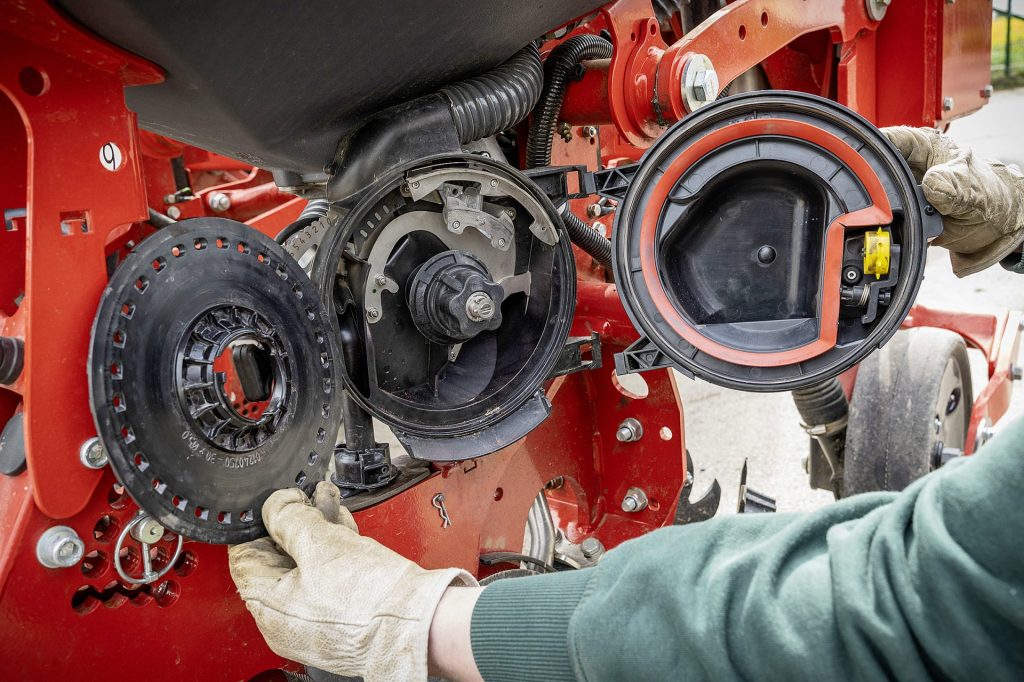

- There are different philosophies for the catch wheel designs: flexible, air-filled, spring-loaded or rigid, open or closed spokes — what works best depends on the sowing conditions.

- The following crop densities (9.5 seeds/m² sowed area) were found on each 2.4km measured section: 7.7 plants/m² (Amazone), 7.6 plants/m² (Horsch), 6.7 plants/m² (KV) and 8.4 plants/m² (Väderstad).

- We would recommend clearing tools when precision drilling direct or into a rough min-till seedbed. Amazone uses a spring-loaded star wheel in front the fertiliser coulter; Horsch and Väderstad opt for a spring-loaded star wheel sited ahead of the seed coulter, while Kverneland does the same but mounts it rigidly.

- In standard spec guise, the machines cost between just shy of £59k and top out at over £75k, whereas, In test configuration, Kverneland is priced at £93,053 (eight rows), Horsch is the cheapest at £79,770 (nine rows, without markers but with lots of special features), and Amazone is asking £97,802 for its well-equipped machine. Just behind the Amazone is Väderstad, which comes in at £93,968.

Summary

When it comes to precise seed placement, Horsch deserves particular praise. Väderstad and Amazone occupied a middle ground position, whereas Kverneland fared less well in the challenging field conditions. Amazone leads this group in terms of seeder handling, followed by Väderstad.

We recommend the machines from Amazone, Horsch and Väderstad for large-scale farmers and contractors, mainly down to their spec, build and level of operator convenience. We consider the Kverneland combination to be suitable for farms who run their own fleets and smaller contracting businesses who don’t have to work the heaviest ground, because the KV drill gets penalty points for coulter pressure, hopper volume and emptying. On the other hand, the Optima’s list price is very appealing, and it did well in last month’s front hopper/fertiliser tests.

Further details are given on the following pages and also appear online at profi.de/einzelkorndrillen24.

Sönke Schulz

For more up-to-date farming news click here and subscribe now to profi and save.