Thanks to their faster work rates, precision planters with overpressure singling are becoming the go-to for maize sowing work. We compared front-rear combinations from Amazone, Horsch, Kverneland and Väderstad. In part one, our attention is on the fertiliser systems, whereas next month we look at seeding precision and machine quirks.

KEEPING IT BRIEF

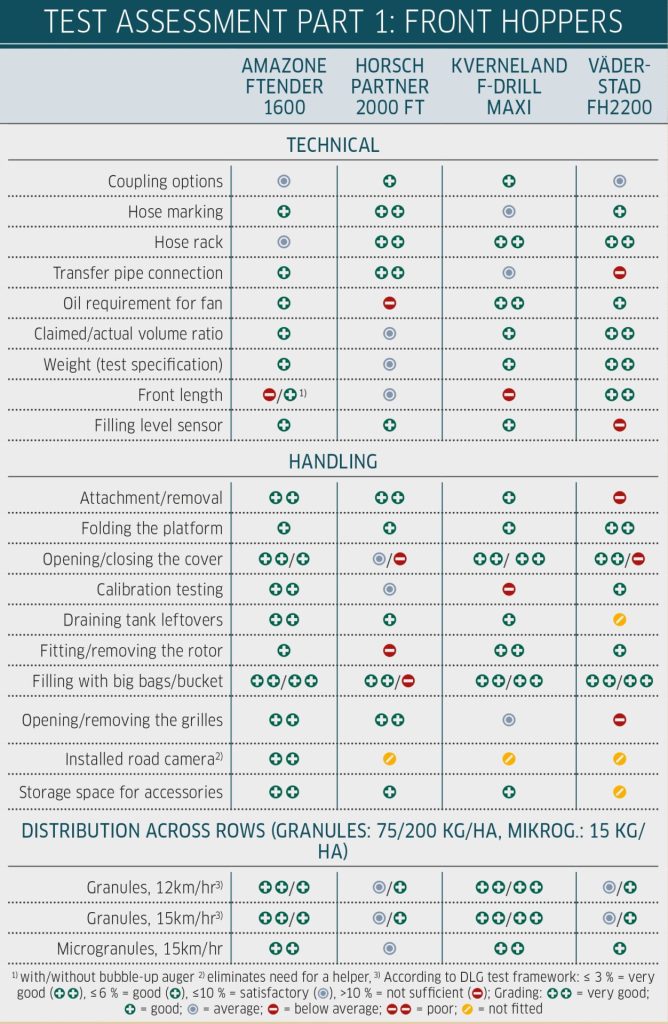

- There are numerous differences between the four hoppers — both in how they work and how they perform.

- Fertiliser distribution across the row varied between 1.5 and 8.0%.

- Hitching up and taking off the front hoppers ranges from clever to outdated solutions.

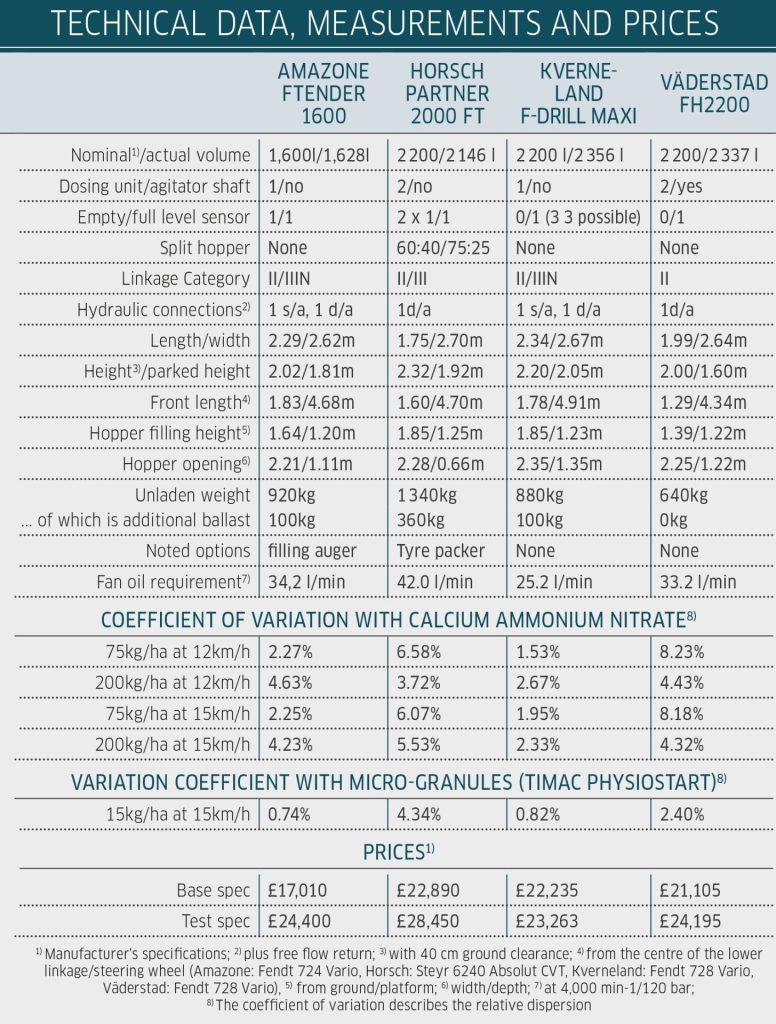

Which drill is best at distributing fertiliser evenly between the crop rows? Which is the nicest machine to use and who offers worthwhile features? These and many more aspects were explored in our comparison test using the four following combinations:

- Eight-row Precea drill with the 1,600-litre FTender from Amazone

- Nine-row Maestro RX with the 2,200-litre Partner FT from Horsch

- Eight-row Optima F from Kverneland with the 2,200-litre front hopper F-drill maxi

- Eight-row Väderstad Tempo V model with 2,200-litre FH front hopper.

In line with the front hopper size, we let the manufacturers decide on the exact spec so they could be best matched with the tractors they came with. Amazone, for example, had installed a filling auger, while Horsch showed up with a double tank, a tyre packer and 360kg of weights.

Here in part one of our test, we focus on the hopper design and the fertiliser systems. In the April issue, we’ll evaluate performance and discuss the details of the planters when used on a row width of 75cm.

Fertiliser distribution across rows

To properly assess the individual machines’ fertiliser distribution systems, we repeatedly collected and weighed the granules from each coulter. The results of this test, at two rates and two travel speeds, are shown within the graphs for each machine from page 26.

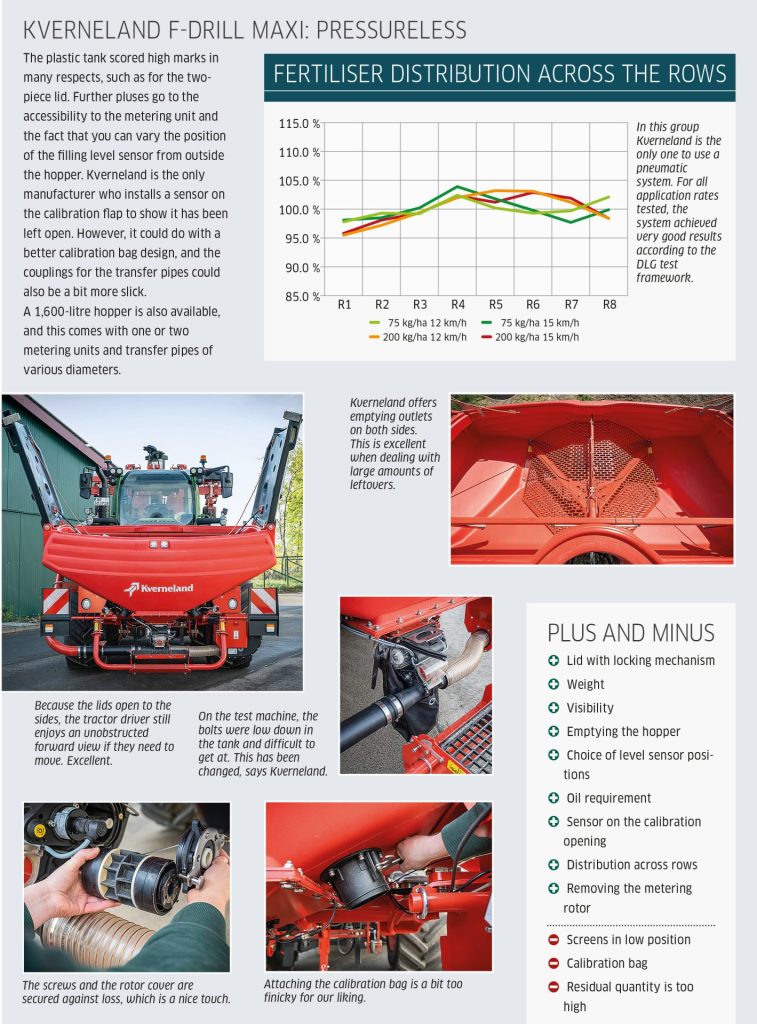

Kverneland is the only one to use an injector system, while all of the others operate a pressurised system. Amazone, Horsch and Väderstad suggest that these latter systems increase the operational reliability at faster forward speeds and result in more effective emptying.

For the test we set the fertiliser target rate at 75kg/ha at 12km/hr and 200kg/ha at 15km/hr. Despite its different approach, the Kverneland achieved the best coefficient of variation (CV) results of between 1.5 and 2.7% respectively. The others were not as consistent.

Amazone achieved a very good CV of 2.3% with the 75kg rate and a good 4.4% for the 200kg/ha. Horsch and Väderstad coped well with the higher application rate (4.6 and 4.4% respectively) dropping to satisfactory for the 75kg target (6.3% and 8.2% CVs).

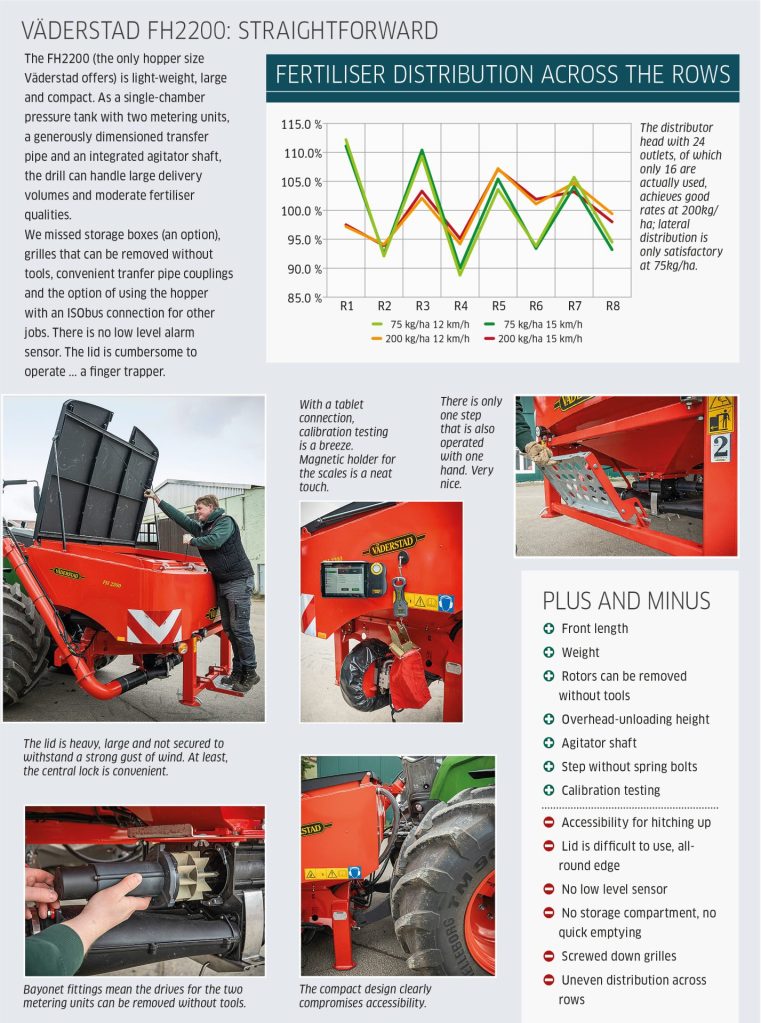

Väderstad produced the most significant fluctuations. This result was attributed to the distributor head, which on our model had 24 outlets: 16 of these went to the eight fertiliser coulters, while the others were blanked off with air-permeable plugs, which resulted in issues with the granule flow.

There were no surprises when we examined the lateral distribution of the micro-granular systems. The various mini hoppers with their electrically powered metering units employed by Amazone, Kverneland and Väderstad delivered relatively uniform rates (CV ranging from 0.7% to 2.4%). Horsch on the other hand continues to use the front hopper for micro-fert, which is delivered pneumatically to the rear, achieving a CV of 4.3% — good.

Specs not the same

Even in their standard spec there are lots of differences between our four test machines, but, with the added extras, there are even more. For instance, on the transfer pipe that connects the hopper and planter, Horsch and Amazone both use quick-fitting over-centre clamps, while Vaderstad and Kverneland rely on a glorified jubilee clip.

Similarly, the sensors used to show the level and when empty are done in different ways. Amazone and Horsch have integrated both sensors whereas Kverneland and Väderstad don’t have a separate sensor in the metering unit — a pity. Kverneland offers some nice flexibility by allowing you to move the level sensor to one of three different positions from outside the hopper. We like the optional castor wheels on the Amazone hopper so you can wheel it into a smaller parking spot when being stored.

Grilles in the tank

Amazone and Horsch stand out for the grilles in their front hoppers; both have basket-shaped grilles that can be opened without any tools. Kverneland’s roof-shaped grille has quick-release fasteners, but it’s down in the tank so access is awkward and doesn’t suit storing spare bags; its design didn’t convince us. Kverneland took our criticism on board and has modified its design since last September. The Väderstad grilles are bolted down, which it explains is a safety measure because of the optional agitator in the hopper’s sump.

With regards to road safety, Amazone has a transverse camera as a factory-fit solution. The other three can supply approved camera systems, either as factory-installed or dealer purchased versions. The reason we mention this is because European legislation states that the maximum distance from the steering wheel to the front of the combination should not be greater than 3.50m. If it is, then you need assistance be it a person or technology such as a camera.

Even on the Väderstad Tempo drill with its extremely short hopper in front of the Fendt 728, we measured 4.34m so it too needs some visual assistance.

Drawback to the compact Tempo design is that you need to be slim to slip between the tractor wheel and hopper when hitching up. Horsch offers far more space for those of us with a slower metabolism and a penchant for cake.

Openings and covers

All models benefit from a good seal between the hopper lid and tank. However, there are major differences with the lid design and operation as well as filling with a bucket or big bags. The split hopper from Horsch has a small, divided opening. All of the other hoppers are at least 2.20m wide on the inside and 1.11m to 1.35m deep, which is fine.

The steel lid on Väderstad’s FH came in for extra criticism as it cannot be safely secured when open, a complaint that also applies to Amazone and Horsch, too. But Väderstad only uses strong gas struts to prevent the cover from closing if there is a gust of wind, and these also make it tricky for shorter operators to pull the lid close. There’s also a flat steel lip that runs around the tank, which you tend to use to support yourself when closing the lid and catch your fingers at the same time — ouch.

The Amazone lid is easier to operate and, like the Horsch, also opens wider than 90°. We would have liked to see rubber strips between the lid and tank on the Amazone, Horsch and Väderstad. We liked the two-part lid on the Kverneland. Even when open, it doesn’t obstruct the operator’s forward view, and we also liked the lever operation on the lids. By comparison, the Horsch lid is secured with four hooked eyelets, one after the other — which is not practical, as they tend to jam. Horsch intends to revise this in the near future on the next generation of Partner FTs — great.

Metering and calibration

The electrically driven metering units are more or less identical, although Väderstad boasts a special feature: two metering units with rubber cell wheels are standard-fit under the hopper, which the company says can achieve rates of 75kg to 300kg without any having to put a hand on it. Calibration testing, too, is straightforward, as only one unit needs testing; the other switches on when required. For lower rates, the metering units alternate when the headland turn is made to reduce deposits.

Amazone, Horsch and Kverneland have the more traditional calibration flaps. Again, Väderstad differs here — you have to take off an inlet from the fertiliser delivery pipe when calibrating. Kverneland is the only one to fit a sensor to warn you if the calibration flap has been left open.

All four test machines have external controls for starting and stopping, and some are supplemented by an external terminal (Amazone), a smartphone app (Horsch) or tablet (Väderstad). There are also hooks, holes and eyelets everywhere for attaching the scales. Väderstad’s powerful magnetic holder for the scales is practical, because it also protects from wind gusts, for example. Attaching the calibration bag to the metering unit is particularly good on the Amazone and good on Horsch and Väderstad, whereas there is still some room for improvement at Kverneland.

Rotor replacement

Swapping the rotor is easiest with Kverneland and Amazone. In fact, Kverneland even secures the removable components so they don’t get lost — neat. Horsch recommends removing the rotor from the rear, because the motor is attached at the front … but it’s cumbersome.

On the Väderstad, the electric motor and metering shaft are removed quickly without tools, though removing the cell wheel does require a tool, which is thankfully stored on the machine. All of the front hoppers bar the Väderstad FH have quick-emptying outlets that are opened without tools. On these machines, you don’t have to operate the rotor for emptying. Brilliant.

Other details

- Amazone and Kverneland have Cat. II and IIIN couplers. Väderstad is Cat. II and Horsch Cat. II or III.

- To hold a fan speed of 4,000rpm, the oil requirement is between 25 (Kverneland) and 42l/min (Horsch, two delivery pipes).

- As a nifty option, the metering units on Amazone, Kverneland and Väderstad can be operated hydraulically as an integral feature within the headland management system and without requiring Section Control.

Summary

Amazone was the standout firm in terms of the front hopper. Many of the details are convenient and quick to use. Kverneland also put in a convincing performance on technology and its even distribution but received criticism for the grilles, which have now been modified, and the awkward solution for attaching the calibration bag.

The main focus of the Väderstad hopper is on functionality. The large tank is compact and lightweight, but it has no fast-emptying mechanism or main delivery pipes that are easy to split without tools, for example. We would also welcome better distribution accuracy across the rows.

The test scores for Horsch were good and average for hardware and handling. These delivery pipes offer the best solution for easy hitching and removal.

Sönke Schulz

For more up-to-date farming news click here and subscribe now to profi and save.