Looking to fight its way into the already busy diet feeder market is Euromilk, a relative newcomer from Poland. We’ve been operating the single-auger 12m3 feeder to see what it is like to live with.

KEEPING IT BRIEF

- Euromilk is based in north east Poland. UK importer is H F Evans and Son from Shropshire.

- The Rino 1200 HD+ is the beefed-up version of the single-auger 12m³ feeder.

- The mixing effect was good. Small things like the very short drawbar let the machine down.

A diet feeder should be able to do one thing above everything else — mix. And this is where Euromilk’s Rino FX1200 HD+ scored top marks, quickly mixing a variety of ingredients.

Before we talk shop, let’s introduce you to Euromilk. The Polish Gama Group was formed in 1996, making milking systems from its factory in north-eastern Poland, situated 150km from Warsaw. The Euromilk name was introduced in 2007, and it built its first mixer in 2011. Today, the firm’s product line comprises horizontal mixers, tub feeders, manure spreaders and slurry tankers.

Back to why we are here, our test machine was a single-auger Rino FX1200 HD+, though British distributor H F Evans and Son says 18 to 24m³ twin-auger machines are proving to be its bread and butter … or, at least, that is where the current demand is.

The drawbar is too short

Starting with tractor/mixer attachment, the drawbar has a selection of height setting hole options to match tractors with different size tyres and hitch heights, so the tub can sit as level as possible during mixing — good. Downside, though, is that the drawbar is too short, so the tractor tyres fouled with either the lowered ladder on the left or the crank for the stand on the right. British importer H F Evans adds that it can supply different lengths of drawbar from the factory in the same way as it can bespoke other features.

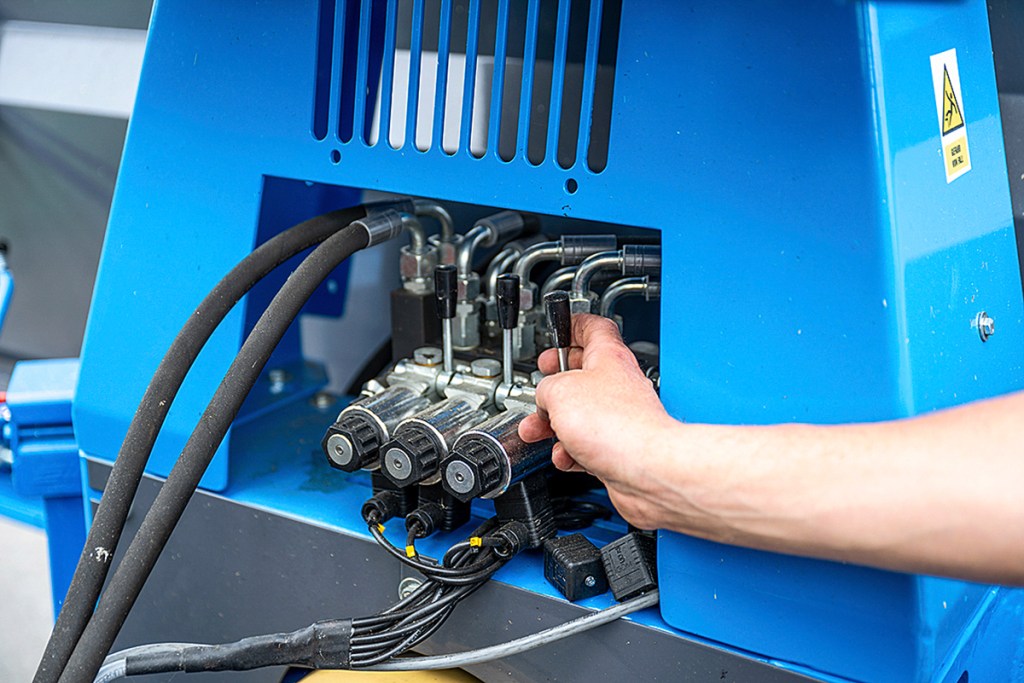

You only need one single-acting spool plus a free return line. Couple the wide-angle pto and the three-pin power plug … and you’re ready to go.

No auto filling

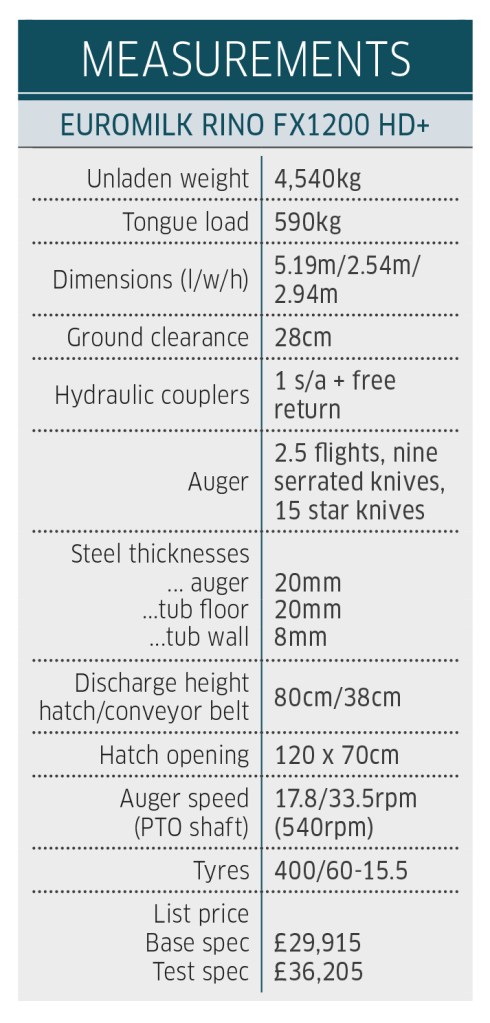

The 12m³ tub has a loading height of 2.94m, which is right at the upper limit for smaller wheeled and front loaders. Incidentally, HD+ stands for Heavy Duty, which for Euromilk means that the auger and the tub floor are made from 20mm steel rather than the usual 15mm. The tub walls on the HD+ are 8mm thick using S355J2+N steel.

Our tested feeder didn’t have the stainless steel lining, but this is available as an option, covering the lower 40cm and costs £1,625. Twin-auger Rino models can have the lower 100cm lined with stainless.

Auger with 24 knives

Feed is mixed by a 2.5-flight auger that sits on a Comer gearbox. Nine curved serrated knives (five long, two short) along with 15 smaller star knives are bolted to the auger; the latter are reversible when worn and only recommended for handling bale silage to prevent over-processing. Replacements cost £43/£56 for the short/large knife and £25 for each star.

The chunky scraper that is fastened to the bottom of the auger has a slotted hole so you can adjust for wear as it happens over the years. A heavy magnet is also on the list of option extras.

In this configuration, the Rino mixer was able to break up a round bale very quickly, the overflow hay ring doing its job of preventing material from being thrown over the top of the tub.

With the two-speed gearbox, the mixer auger operates either at just under 18rpm in the low speed setting or 33.5rpm in high. In the low speed the power requirement was about 30kW/40hp to mix our ration.

It took less than 15 minutes to mix the straw, grass silage, maize silage and compound into a homogenous feed. We set the post-mixing time to about five minutes, which was plenty of time for the straw to be well chopped and mixed in.

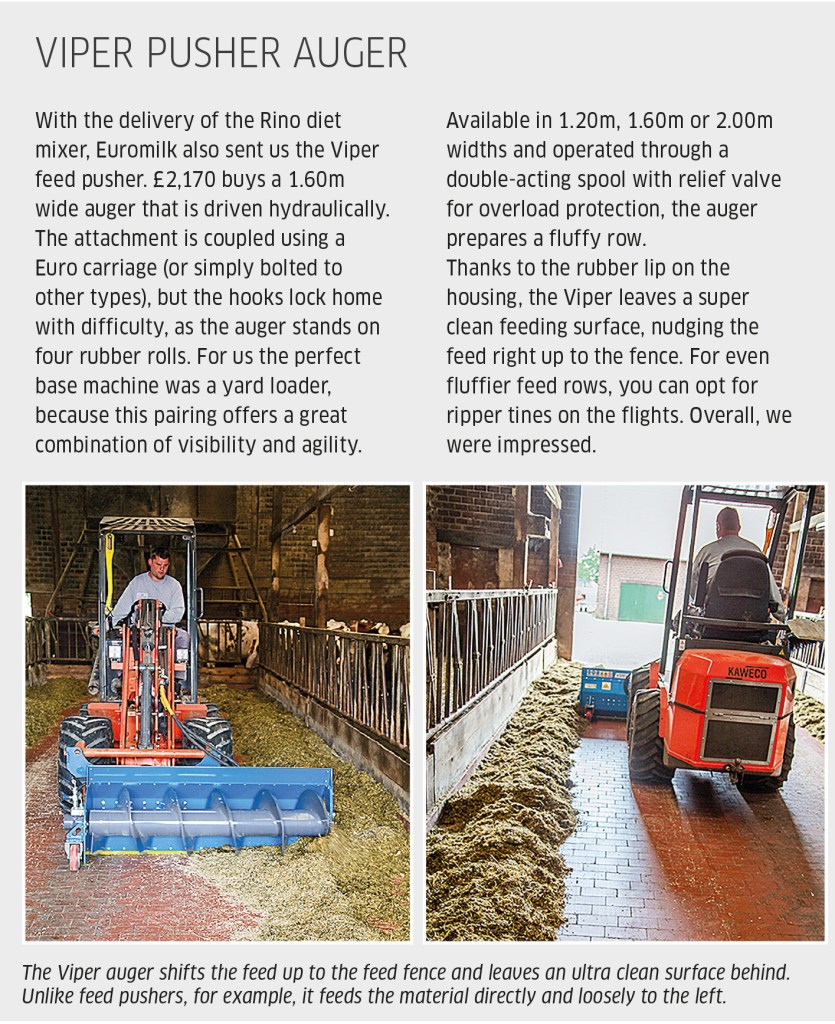

Door or belt

On our Rino we could feed out using either the front-mounted cross conveyor or direct through a door on the rear left. The door’s chute can be adjusted by refitting a chain so feed is dropped closer to the feed fence. Downside is that it doesn’t always feed out evenly like the cross conveyor does. The belt speed for the wide conveyor is set using a restrictor valve.

How far you open the door sets the feed-out rate for both discharge options. Once the tub is half empty, you can change over to the high speed. Our feeder had an optional Bowden cable for this. If you also select the 1,000rpm pto on the tractor, the mixer will completely empty itself, with little in the way of feed remnants.

We placed the two counter knives in their halfway position, as this not only improved mixing but it also reduced the overall width in some of our narrow feed passages. When fully out they risked catching on gates and doors. When the counter blades are fully in and the feed-out chute lowered, the overall width is 2.53m. The length of our FX1200 was 5.19m.

Italian scales

Euromilk sources its weighing system from well-known Italian maker Dinamica Generale in Italy. There are four weigh cells beneath the tub that worked both very reliably and accurately. Our test machine also came with the DG500 terminal (£400) over the base DG400 unit. Tech-savvy livestock farmers can program up to 24 mixes consisting of up to 18 constituents. And it is also possible to calculate the amount of feed per cow so that the recipe automatically changes when the animal weight or numbers vary. The screen was clear and readable, even in very bright sunlight. Sadly, work lights and a reversing camera are not offered.

Summary

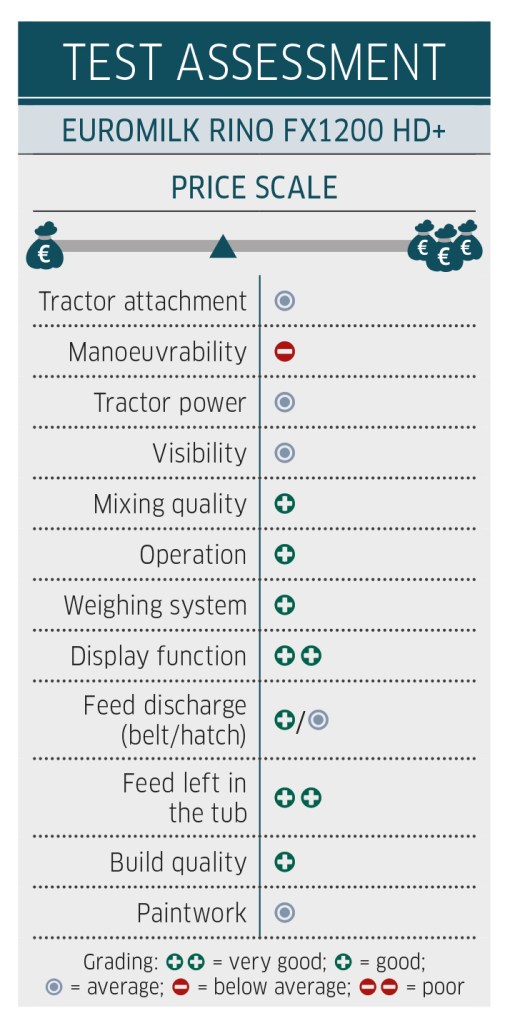

With the Rino FX1200 HD+ model, the Polish company offers a simple but practical diet mixer. The functions of the mixer, the scales and operation are good. However, the short drawbar was a constant issue for us. In the tested configuration, our particular mixer costs £36,205.

Tobias Bensing

For more up-to-date farming news click here and subscribe now to profi and save.