Deutz-Fahr was at the forefront when it came to developing better visibility with its sloping ‘snoopy’ bonnet tractors in the late 1980s. We take a look at the two large AgroXtra models from the original steep nose bonnet range.

KEEPING IT BRIEF

- The idea of the sloping bonnet came from Deutz-Fahr’s Swedish importer Söderberg & Haak, which initially converted a 4.51 on its own.

- Signs of low hours include the wear on the clutch pedal, steering wheel, gear sticks and floor mat.

- If you want a turbo charged six-cylinder with a snoopy bonnet, you will need to search for one of the AgroStar models.

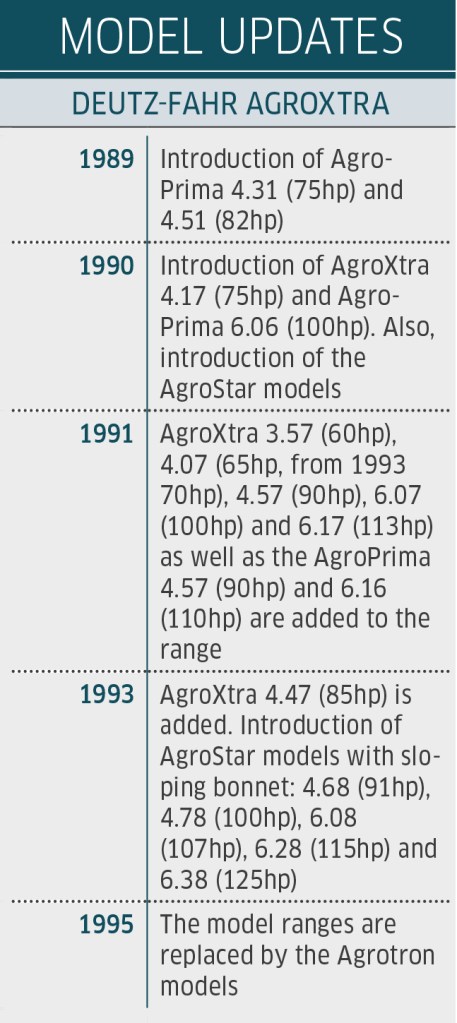

Deutz-Fahr introduced the AgroPrima series in 1989 with the new StarCab cab. Initially, the range comprised two four-cylinder models; then, a year later, another four-pot and two six-cylinder tractors followed suit (see ‘Model updates’ on page 85).

Also in 1990, Deutz-Fahr presented the AgroXtra, the first high-visibility tractor with a sloping bonnet, which was based on the AgroPrima. The series comprised the little AgroXtra 3.57 (60hp, three-cylinder), a quartet of four-pots with the AgroXtra 4.07 to 4.57 models (65hp to 90hp) and the AgroXtra 6.07 (100hp) and 6.17 (113hp), each with six cylinders. In 1993, the snoopy design was also adopted on Deutz’s lower horsepower AgroStar tractors.

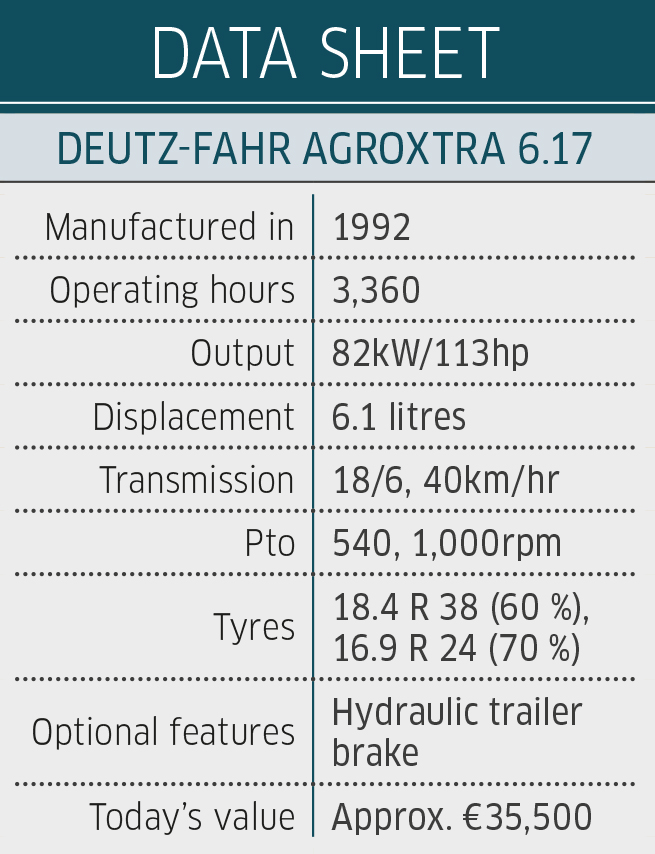

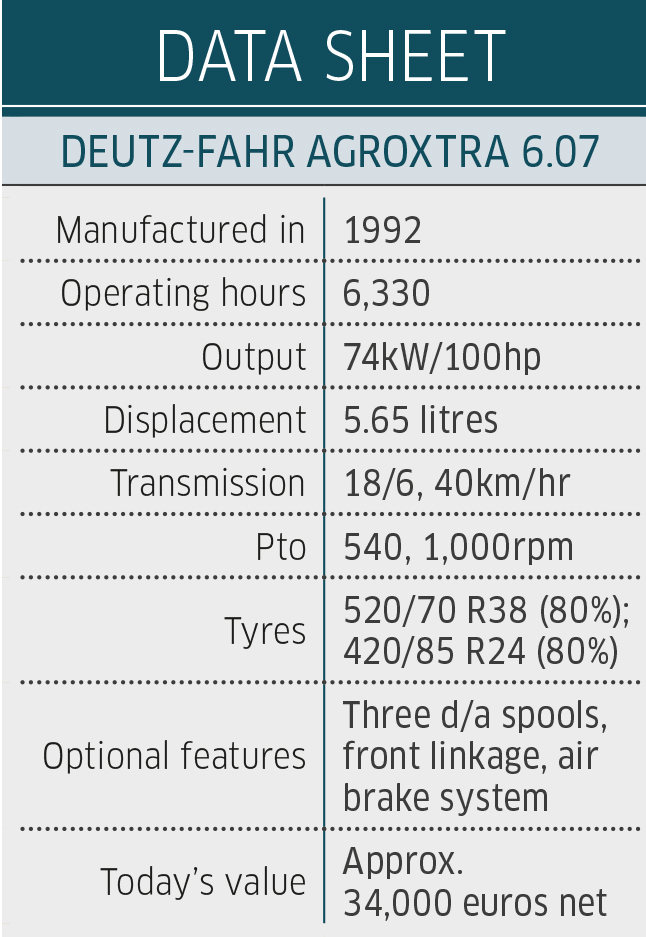

The AgroXtra 6.17 pictured here, with just 3,400 hours, was up for sale with farm kit dealer Benedikt Schulze Lammers in Borken on the German-Dutch border. Farmer Marcel Barenbrügge from Legden further west of Borken actually bought his AgroXtra 6.07 from the dealership only a few months ago.

“I was looking for a second tractor to back up my Agrotron M620,” he recalls. “The low number of hours, the level of specification and the very good visibility were the main reasons why I bought it,“ Marcel explains.

For this article we also spoke to Andre Venhoff, who runs a farm and construction machinery dealership in Borken. This dealer specialises in older Deutz tractors.

No major changes

The AgroXtra tractors are largely identical to the AgroPrima machines, which were initially still badged DX. As it doesn’t have a water cooler on the air-cooled engines, the main noticeable difference is the position of the air cleaner, which had to be moved for the sloping bonnet version. Another detail is that the battery relocated from being in front of the engine to a box under the right- hand side of the cab where it is much easier to get at. Another important change is the shortened partition in front of the engine and a downward-angled housing for the cab’s air filter in front of the cab. As with the AgroPrima, the side panels can be easily removed and the bonnet folded up.

Six-cylinder naturally aspirated engine

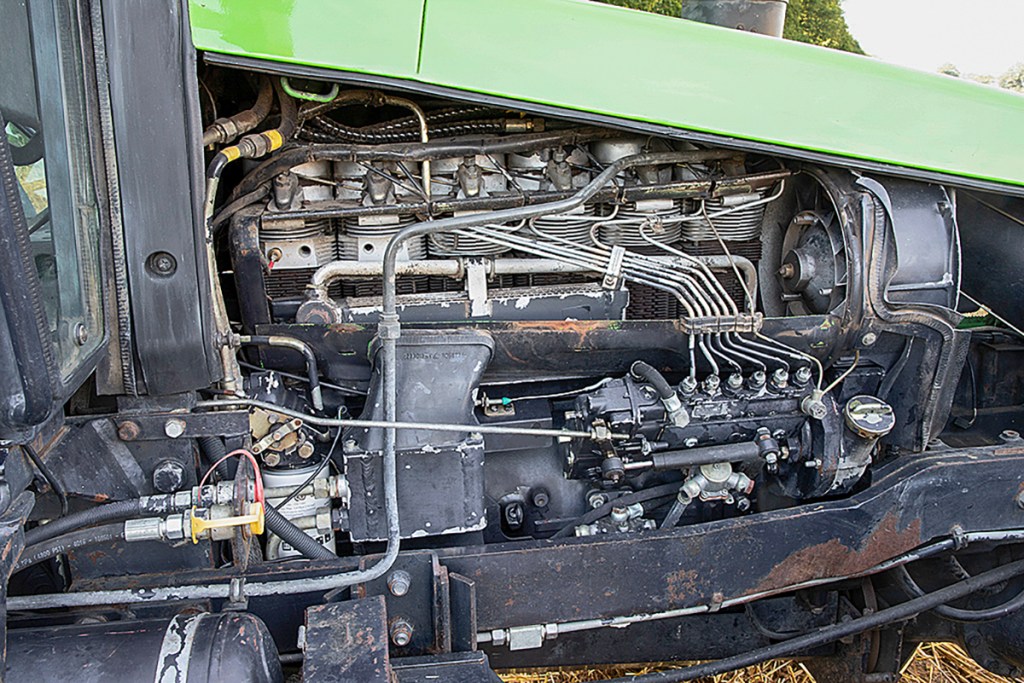

The 6.07 is powered by an F6L 912 with a displacement of about 5.6 litres and the 6.17 by the slightly larger 6.1-litre, six-potter F6L 913 motor.

The aspirated engines are considered robust as long as they get enough air to keep them cool. Check the area under the sheet metal of the air duct on the right-hand side of the engine. Are the fins around the cylinders dry and ideally clean? If, for example, a valve gasket leaks and the mix of oil and dirt runs down the ribs and dries there, it may cause overheating when the tractor is working hard.

“It’s usually cylinder one, the one that sits right in front of the cab, that has an issue with air supply. So, pay extra attention to the cooling fins here,” recommends Andre Venhoff. The ventilation grilles in the bonnet should be cleaned regularly, especially when operating a front mower.

Also, make sure the cylinder head gasket isn’t blown, which can easily be recognised by hissing noises in the engine compartment. Occasionally, unnoticed overheating causes some aluminium heads to warp slightly so compression escapes. The only fix is to grind down the head and replace the gasket.

“At worst, overheating can lead to piston seizure,” points out Andre.

Manual gearstick

You won’t find a powershift transmission on the AgroXtra. This is only used in the AgroStar, which has one powershift step as an option. The gearboxes with the names TW-902 (6.07) and TW-903.3 (6.17) are six-speed transmissions with three ranges when driving forwards. This results in 18 forward and six reverse speeds. A creeper box was an option and indicated by the letters LL on the gear knob.

In addition to a 540rpm pto at rated engine speed, there was a choice between 750 and 1,000rpm. The tractors we took a look at were equipped with the rather more common 1,000rpm shaft.

The gearboxes are generally considered to be largely OK. Handy signs of wear are more common on the gearshift linkages, especially on tractors that have clocked more than 8,000 hours. However, any issues here are usually solved after removing the gearbox cover and replacing the spring sets.

During the test drive, you should also listen out for noises when starting off, which could be caused by broken or loose bearings in the axles. By the way, the ‘6’ series AgroXtra models have larger axle trumpet housings with 275mm hubs than the four-cylinder models with 205mm. Also, carefully inspect the hollow drive shafts between the engine and gearbox. Another useful sign of wear is a distinctive running noise when you operate the clutch.

Front axle and brakes

The Sige front axle is equipped with the OptiTrac limited slip diff. If oil changes were neglected or the wrong oil was used, the diff clutch can become damaged. If it doesn’t disengage properly, you will notice the noise it makes when you travel at faster speeds on a road test. Make a point of looking at the vertical play on the front axle, especially on tractors equipped with a loader. Can you wobble the wheels back and forth? If ‘yes’, the bearing in the pivot housing is probably goosed.

You should also check the brakes. If there are vibrations in the front axle, this is often caused by a warped brake disc on the prop shaft brake. Brake disc replacement is the only remedy here. “It can happen, especially with tractors from abroad, where the brake has been completely disconnected. This ‘mod’ invalidates the operating licence of 40km/hr tractors here in Germany,” points out Andre.

The rear axle is also home to outboard disc brakes. These brakes are easy to access and maintain. Problems occur when the tractors are parked up for lengthy periods and the brakes are exposed to moisture and dirt. The brake cylinders then tend to rust, which in the worst case can result in the brakes overheating.

The ravages of time

And, speaking of rust, this is an important indicator of the condition of an AgroPrima or AgroXtra.

Weak points include the doors with single-piece windows and the mudguard frames. If water penetrates into the door frame or between the mudguard and the bars, it can lead to severe rusting.

You should also take a look at the three- point linkage. Especially on the four-cylinder range, there are models with either none, one or two assister rams. The six-pot models, on the other hand, are usually equipped with two and can lift about 6.5 tonnes. Otherwise, the AgroXtra’s hydraulics are pretty simple: a tandem gear pump supplies the steering system with oil and duly delivers around 55 litres/min of oil at 175 bar to the spools.

Electronic elements such as ‘Agrotronic’, which are the digital instrument cluster and electric lift controls, were available as an option, but none of the AgroXtras we viewed had them. If you want such electronic aids, you’ll have a better chance of finding them on AgroStar models in particular.

Summary and prices

AgroXtra are simple, robust tractors that offer excellent forward visibility. Which is why they are particularly popular for any applications that require the front linkage, front pto and front loader.

The bigger six-cylinder machines start at around €20,000 for examples with 10,000 hours or more. Well-maintained models with fewer hours can cost up to €35,000 if you go shopping in Germany.

Closer to home, you have dealers such as Devon-based S Cheers Agri Engineering or Parris Tractors who occasionally have this era of Deutz-Fahr. If you spot a good ‘un, go for it, because they tend to get snapped up.

CONTACTS FOR USED PARTS

- Stefan Booms, 46414 Rhede, Germany, stefan.booms@web.de

- Frick & Aurbacher GmbH, 87724 Ottobeuren, Germany, frick-aurbacher@t-online.de, frick-aurbacher.de

Alexander Bertling

For more up-to-date farming news click here and subscribe now to profi and save.