The auger-based Direct Swather allows the plain Claas triple mower to merge three rows of crop into a single row without the weight or power penalty of the merging belts on the conditioner-equipped Disco. We were intrigued.

KEEPING IT BRIEF

- A minimum of 180hp is recommended for the 9.10m triple.

- Conical augers merge the outer two rows.

- Sensors warn the operator of overloading.

Another Disco has joined the Claas mowing party. Where the plain mower triple 9300 Direct Swather is different from the rest, is that it uses augers on the back units for merging crop into a central row. This new addition is primarily targeted at farms that like to do their own work and operate smaller tractors.

Tipping the scales at 3,000kg for the back mowers, it is around 400kg lighter than the conditioner model with a belt-based grouper. Yet another advantage of the DS is that the compact design moves the centre of gravity much closer to the tractor.

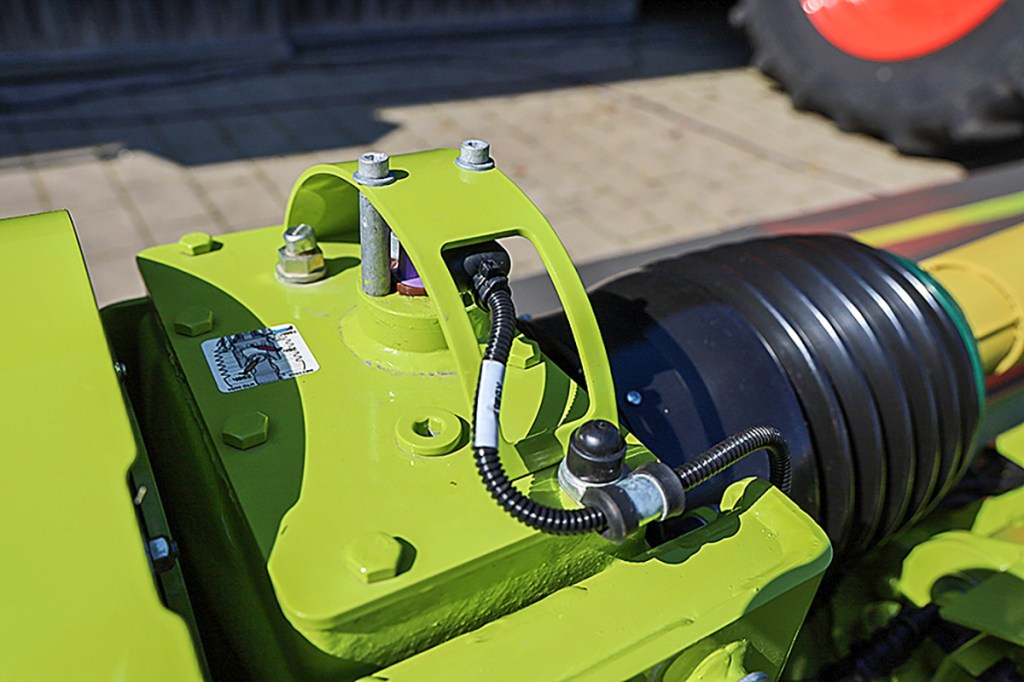

The Max-Cut beds are familiar Disco mowing hardware. Spare blades are usefully stored in a portable toolbox. The two mowers are suspended by load-sensing hydraulics, with a gauge located by the headstock indicating the current pressure.

There is the option of a slope sensor that controls the bed pressure differently on the right and left sides to prevent crabbing. Two visible arrows mark the correct height of the lift arms, and cutting height is adjusted by altering the length of the top link.

Conical augers

The main feature of the 9300 Direct Swather is the new auger-based merging system. Crop flows from the cutterbar to the augers without the need for a conditioner to aid forage on its journey.

The chunky auger flights in the middle are twice as high as those on the outside, and the distance between the rear wall and the auger also increases as the crop exits — a conical design. To ensure the auger keeps a consistent distance from the bed, so it keeps moving the crop away from the cutterbar, the auger is mounted at a slight angle.

A knife with a counter blade is attached to the end of the auger, preventing crop from catching and then causing a plug. Drive to the auger is from an externally mounted V-belt working at a fixed speed. There is a separate swath deflector on either side that can be raised/lowered hydraulically to give some control over the row shape.

If you don’t want to merge, then the entire auger unit lifts up for wide spreading; this can be done on the move, and you can also control the left and right augers separately. This not only lowers the power demand and reduces wear, but it also protects delicate crops. Speaking of power, the 9.10m wide set of triples can be operated with 180hp or more.

Drive and overload sensor

The 9300 DS mower is controlled via ISObus. Various sensors are integrated in the central gearbox and in those on the mowers for overload protection. If a speed difference occurs, a message warns the operator of the impending overload. This gives them the chance to react before the friction clutches are triggered, saving time and wear.

It’s driven by a 1,000rpm pto shaft, but, like the other Disco models, this can be reduced to 850rpm, depending on conditions. Doing so can save up to 22% in fuel use, according to Claas.

To reduce the amount of wear, the driveline runs in a straight line. The mid-mounted gearbox splits the power to both sides and on to driveshafts on the mowers, where the gearboxes distribute the power out to the direct-drive cutterbar and the pulleys that drive the augers.

The swathing experience

We were able to use the 9300 to mow triticale for wholecrop silage and then went on to drop some second-cut grass. Both were heavy and wet crops. In the grass, the augers formed a uniform swath, but when harvesting the triticale the augers produce a much more uneven row that will challenge the forager. By comparison, the mower outfit working alongside with a belt grouper left a more uniform swath.

Operation of the mower is convenient and clear. Contouring also works well in uneven terrain. Claas’s overload protection system reliably protects against friction clutch wear, and the hydraulic break-away system is designed to protect against impact damage. All good there.

Who are the customers?

The 9300 DS is particularly suitable for farmers who don’t want to condition but do want to merge three rows into one. It can also be used on smaller tractors. For high-yielding wholecrop, however, we still believe the AutoSwather belt merger is the better choice.

At a list price of around £85,100, the machine is a good £14,750 less than the Disco 9300C Auto Swather.

Sebastian Rüther

For more up-to-date farming news click here and subscribe now to profi and save.