TECHNICAL: There are various solutions for precisely spreading granular fertiliser along field boundaries. Ulrich Lossie, from Deula Nienburg, gives this low-down.

KEEPING IT BRIEF

When spreading next to a watercourse, no fertiliser granules must land outside the permitted area.

Boundary deflectors are controlled hydraulically or electrically.

The deflectors alter the throw and speed of the granules.

Spreading right up to the boundary is possible with central deflectors, but not without an additional tramline.

Spreading fertiliser products along field boundaries demands precision, even more so where there is a watercourse or public path or road. But achieving this with a broadcaster can be tricky: not only is each type of fertiliser different, but there can also even be variations in each batch of fertiliser that impact its flight characteristics. Granule size, hardness, surface roughness and number of smaller granules in the batch are some of the physical parameters that have a strong influence on distribution — especially along field edges.

Bear in mind that nitrogen and phosphorus are much more relevant for the environment and legislators when compared to fertilisers containing sulphur, potassium and lime, for example … although it is obviously in every farmer’s interest to apply these costly inputs in the fields and not beyond.

Field margins differ

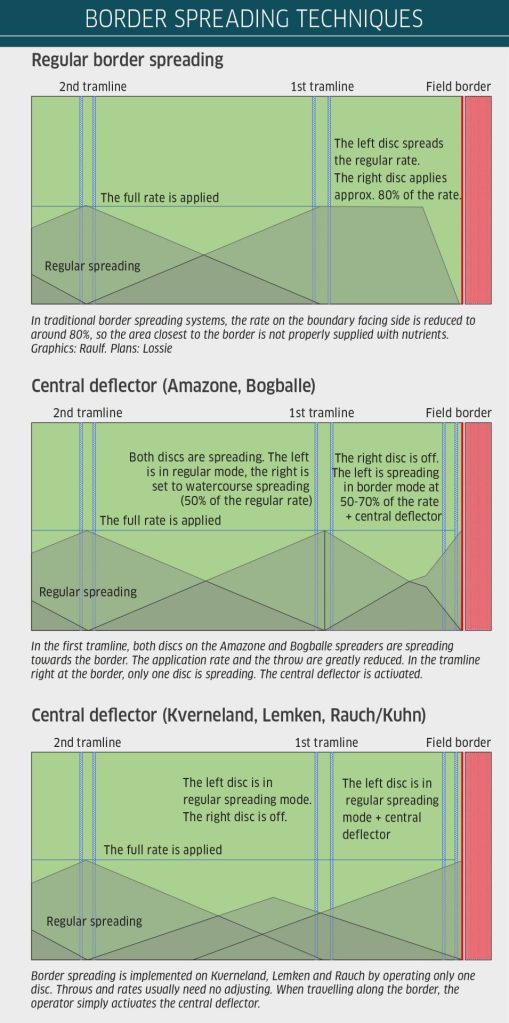

The rules are not as strict for spreading along fields and verges where a few granules are tolerated just beyond the perimeter. However, this is clearly taken much more seriously when spreading along watercourses, when not a single granule is tolerated outside your field, not even if a gust of wind carries it beyond the targeted crop.

Some broadcaster companies offer spreading charts with just two border scenarios, namely yield-oriented boundary spreading work and environmentally optimized border spreading. For stricter spreading along watercourses, users often have to re-measure and adapt the supplied settings.

We will describe how you can best achieve this in next month’s profi when our team will be testing various border spreading systems.

There are several ways of striking the best balance between environmental protection and optimizing yield potential. The border spreading discs on older broadcasters can be adjusted to match different fertilisers with good results as long as you put the time in to make the necessary adjustments. But this is not always practical for many farmers.

Limitations of the side screen

A hydraulically engaged deflector is a much more popular option for many users and is generally not that expensive an option if not part of the standard machine. Indeed, on most makes it is possible to retrofit such headland deflectors on the left or right.

However, this type of system can clearly reach its limits on fertiliser spreaders with large working widths, because the granules continue to be thrown at full force, smacking against the deflector plates, which can lead to wear, dust formation and drift. In addition, it is has been observed that as individual granules fly in an arc as they leave the vane, they can miss the deflector and land several metres outside of the field.

But arguably the main disadvantage of using side-mounted boundary screens is that not all operators will make the necessary changes to the deflectors to match the fertiliser or type of boundary. This is why newer systems offer better solutions.

An electric deflector

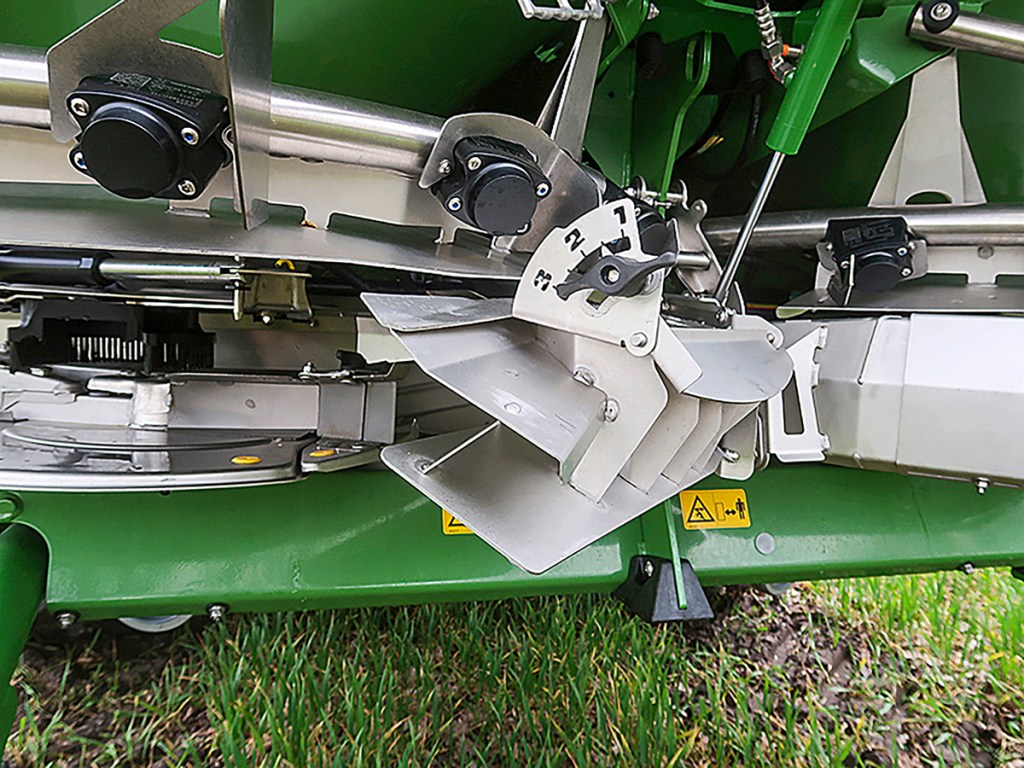

Amazone markets its second generation of deflector screens as Limiter V+, this newer version replacing the hydraulic ram with an electric linear motor. This set-up allows users to conveniently switch between spreading along field margins, borders and watercourses without having to leave the tractor seat thanks to the linear motor adjusting the height of the screen almost continuously.

Secondly, the adjustable vanes differ in length and geometry to produce the desired patterns. The initial set-up of the headland unit is straightforward. The operator simply slides the screen to the side by operating an easy-to-use locking lever; there is no need for tedious spannering.

On its TS spreaders, Amazone uses additional short wings on the spreading discs, the so-called TS wings. When spreading along field margins, the long vanes direct the granules to the short TS wings. This standard boundary spreading system works in much the same way as using boundary spreading discs — the big difference being that the TS operator selects boundary spreading from the cab. This engages an electric motor installed on each of the disc gearboxes, and the motor can be switched on at full disc speed.

One of the two TS wings on each disc can be telescoped to one of three positions, adapting the throw to the flight characteristics of the fertiliser. Amazone offers these telescopes in four different lengths to suit different types of fertiliser and working widths.

A handy design feature that’s not available on the TS spreaders is the option of adjusting the granule feed system or the drop-on point separately on the side that is travelling along the boundary. Switching between border and watercourse spreading is done by adjusting the disc speed. This is always a compromise on machines with mechanical drives, because this changes the speeds of both discs, the one that faces the border and the one that faces the inside of the field.

Alter the impact point

Fert spreaders that have hydraulic drives (e.g. Kuhn/Rauch Axis, Bredal F series) offer a simpler solution of reducing the speed of the outer disc independently of the inner disc. This means that the granules are dropped off with less energy. A change in speed always has two key effects: it influences how far the granule will travel and the take-off position.

Reducing the disc speed causes the vanes to carry the granules over a longer distance. Therefore, most spreaders throw them more towards the edge of the field. If on a hydraulic drive broadcaster it is possible to adjust the impact point at the same time, the spread pattern is even more controllable.

Change the direction of rotation

Bogballe has been doing its own design thing for many years when it comes to the task of border spreading. In contrast to most of the centrifugal spreaders from other companies, the spreading discs on Bogballe (and Bredal) machines rotate from the outside inwards. This allows both the left and right spreading discs to spread over almost the entire throw width, creating a double overlap.

When spreading along the boundary, though, the main issue is that it is not sufficient to just reduce the spread width on one side only. This explains why Bogballe has relied on a double-sided vane and alters the direction of rotation for spreading along borders. But this solution has three minor drawbacks.

Firstly, boundary spreading is only possible on the right-hand side of the machine.

Secondly, the operator must switch off the pto to change the direction of rotation of the gearbox.

Thirdly, when spreading at larger widths the system has an impact on the spreading pattern on the inside of the field.

At the last Agritechnica, Bogballe presented a free software update for its 27m to 42m broadcasters that have section control. This approach to border spreading allows users to alter the feeding point and disc speed without changing the direction of rotation.

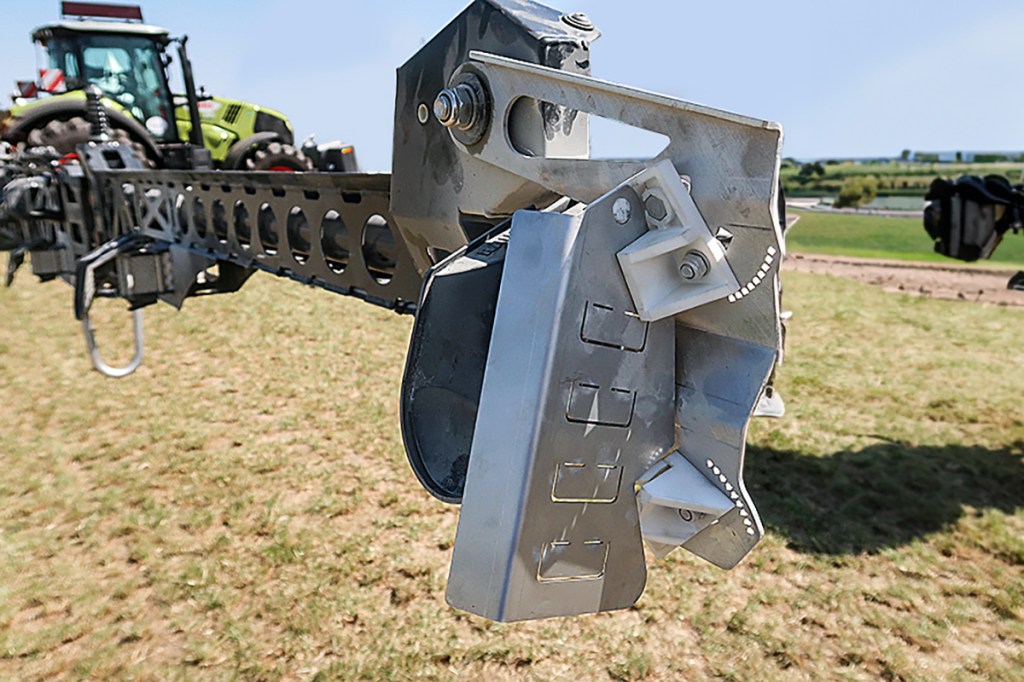

A mid-mounted deflector for sharp edges

Anyone who plays ball sports knows that the shorter the distance, the higher the hit rate. Consequently, any fertiliser application along field boundaries will be more accurate if the granules are spread right along the border. To achieve this, many manufacturers such as Amazone, Bogballe, Kverneland, Sky and Kuhn offer systems with additional deflector plates mounted in the middle. These deflector plates supplement the standard headland spreading system. The extra plates not only make for an accurate application along the border, but, unlike systems with side plates, they do without operators having to adjust the discs to field margin, border or watercourse spreading.

The drawback of using central deflectors is that they increase wheelings, because you have to make one extra pass directly along the field boundary. This is obviously time consuming, and, perhaps more critically, can cause compaction in a wet spring.

Moreover, as early as the second nitrogen application, especially in oilseed rape, many farm managers opt against such soil damage and using the mid-mounted deflectors. And even if the spreading charts do not give any corresponding recommendations, it is worth considering increasing the nitrogen application by approx. 20 to 35% for the first border run using a machine with a central deflector.

Other details

Sky (which makes spreaders for Lemken) utilises a third vane on the spreading disc. The centre piece of this so-called Tribord system is an electrically operated actuator. In border applications that focus on yield optimisation, this vane redirects material in such a way that some product is thrown from the regular long vane into the border spreading vane. In environmental boundary spreading, all granules are spread by the boundary spreading vane and the regular short vane.

Pneumatic spreaders have factory-fitted border spreading plates that apply the fertiliser precisely along the border after the plates are appropriately adjusted.

For another type of fertilising, i.e. for the application of liquid fertilisers, the special border spreading nozzles are still rare. As the typical FD nozzles apply liquid about 50-80cm beyond the field margin, a special border spreading nozzle control system is absolutely necessary. The only company that offers a nozzle that’s suitable for border application is Lechler.

Summary

The wider a machine’s working width, the more difficult it is to apply the desired amount of fertiliser up to the edge of the field but not beyond it. In reality, this can leave plants in the last third of the tramline width lacking the required nutrients, which inevitably leads to yield loss and potential profit.

Unfortunately, in recent years, many firms have focused on convenience rather than precision when it comes to border spreading. All the well-known spreader manufacturers now offer good solutions that combine both requirements: an even distribution inside the field and a sharp application line along the border.

We’ve recently tested a selection of the most important systems for you, and we’ll present the exciting results in our next issue (profi 12/2024).

Ulrich Lossie, Anja Böhrnsen

For more up-to-date farming news click here and subscribe now to profi and save.