With its nominal volume of 5,000 litres, the Amazone ZA-TS 5000 is a big lump of a mounted spreader. This makes it perfect for spreading light urea, although heavy fertilisers also fall within its remit.

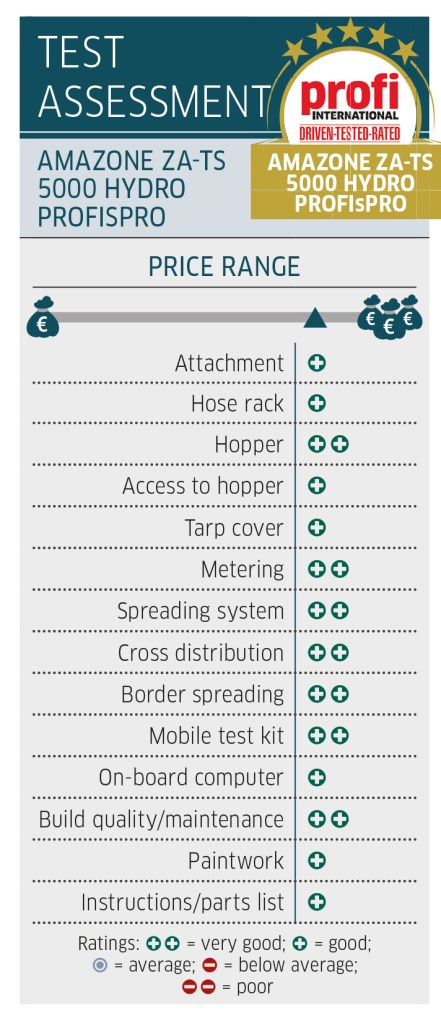

KEEPING IT BRIEF

- The ZA-TS in this configuration can really cover ground quickly.

- Extensive options help to optimise spreading, but every option may not be essential for your needs.

- Amazone has made some noticeable improvements to its paintwork which we found to be very good on the test machine.

Amazone has increased the hopper capacity of its well proven ZA-TS mounted spreader models, which can now hold up to 5,000 litres.

However, this applies only to lightweight fertilisers such as urea, because the max payload is still 4,500kg — something to be aware of. To be certain of this, Amazone has included an automatic warning into the software that sounds when overloaded by more than 5%.

The complete name is ZA-TS 5000 Hydro ProfisPro. Which means the following:

- ZA: Centrifugal broadcaster, mounted

- TS: AutoTS boundary spreading system

- 5000: Volume in litres

- Hydro: ISObus with hydraulic drive

- ProfisPro: Weighing technology and torque measurement.

Straightforward attachment

The fertiliser spreader couples via Cat. III linkage spacing. Next, there are the hydraulic connectors for the load-sensing system, which on this machine were in charge of the hydraulic drive of the spreading discs, a £4,550 option.

Then couple a double-acting spool for the hydraulic cover (£1,730) and the BorderTS boundary system. Both of these couplings have exemplary plus/minus decals, though unfortunately there is no decal to explain which colour marks which function. The light and ISObus plugs have to be connected — and that’s it.

Generous dimensions

The ZA-TS 5000 hopper is 2.85m wide. The front end where the ladder is (which has already been improved) measures 2.87m; the rear end where the lights are is 2.97m. As for height, it’s 2.47m when you include the parking stand, 1.98m when the wheels are folded. At 2.80m wide and 1.38m deep, there is sufficient room for filling bulk fert with a loader bucket.

When it comes to paint, Amazone uses both cathodic dip painting and powder coating for the finish, the factory now including a seven-year warranty against rust.

Spreading system doing a proper job

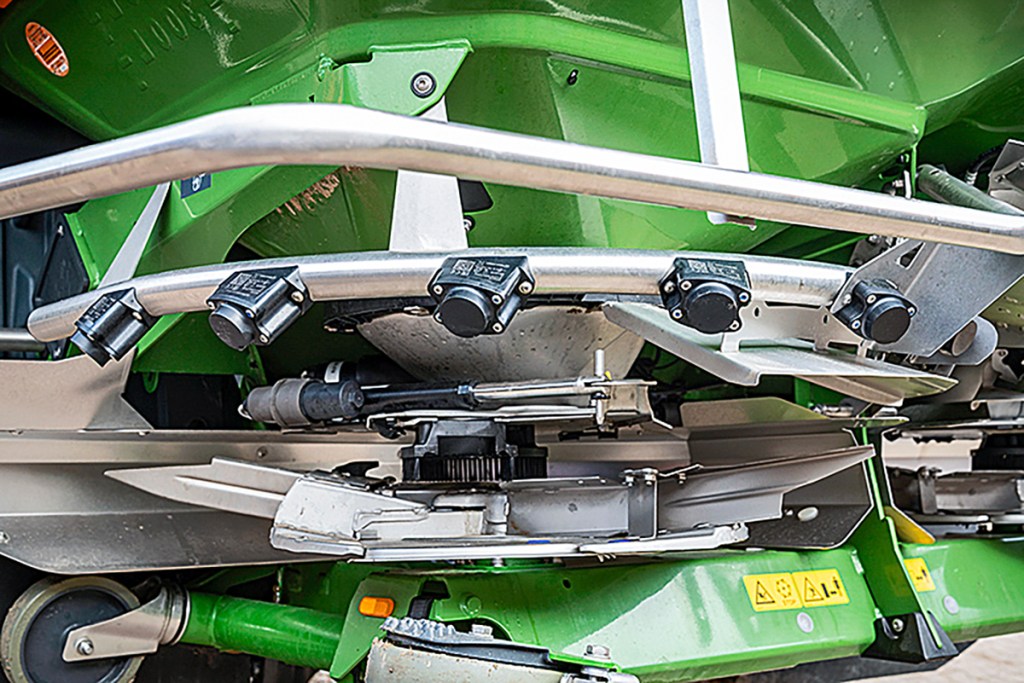

The stainless steel TS spreading unit consists of the following components: hopper outlet agitator, electric motors for adjusting the rate and drop-on point plus the spreading discs with regular and border spreading vanes.

The boundary spreading vanes are activated electrically. The agitator in the feed hopper is driven by a motor at up to 60rpm and is switched on only when required, which means that it’s in action when the shutter is open, and out of action when the shutter is closed. And if there’s a blockage, the agitator reverses.

If the spreading pattern changes when the application rate increases, this is referred to as a rate effect. For this, Amazone designed the metering aperture in such a way that the contour of the outlet matches exactly the path of the slider. In our experience, this means the spreading pattern is maintained even when rates vary.

The brush under the hopper ensures the granules land safely on the disc. The impact point is controlled by a servomotor that rotates the brush above the disc. Depending on the impact point, the spreading width can be varied between 15m and 54m along with swapping the vanes and altering the disc speed.

Easy spreading width control

If you often deal with different throwing distances, you can easily swap the vanes — which is faster than refitting the whole disc. For normal spreading, the ZA-TS overlaps twice. This applies to a working width of up to 36m, which makes the spreading pattern relatively resistant to crosswinds or varying fertiliser qualities.

We checked the lateral distribution with the EasyCheck mats (£325). We positioned the plastic mats across the working width, did one spreading pass and then took a picture of the result on our smartphone. Amazone’s app then calculates the optimum settings for the spreader. We didn’t have to make any adjustments to the initial settings, which were correct first time.

Always right on the border

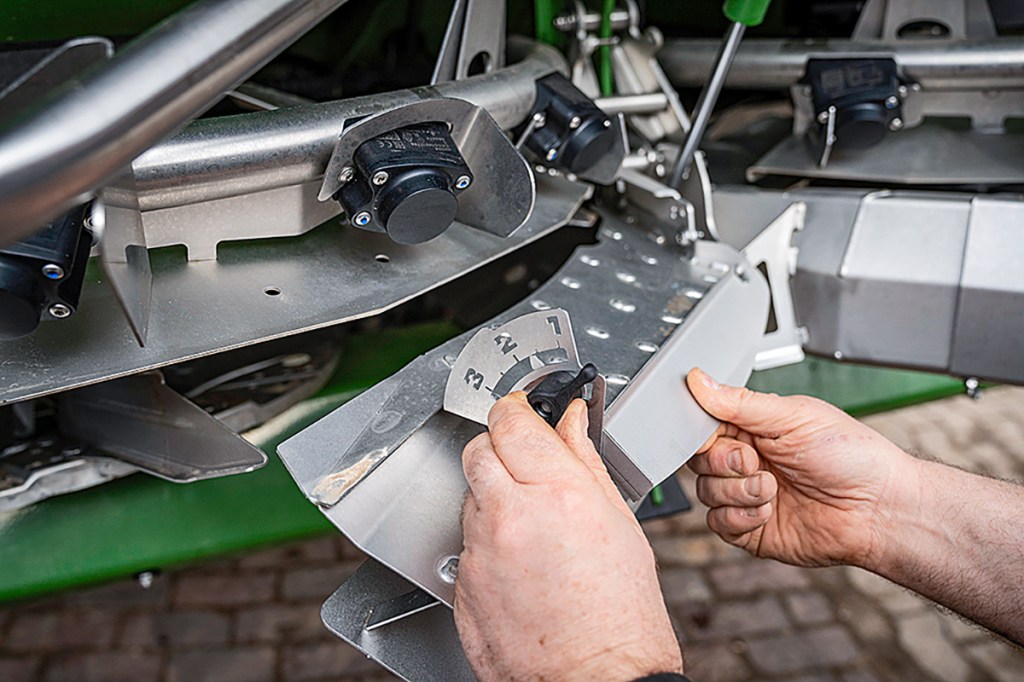

For boundary spreading, Amazone utilises its AutoTS boundary spreading system on the ZA-TS. Here, an electric motor swivels the feeding vane on the spreading disc by around 10° so that the granules are spread by the short border spreading vanes. These vanes have to be adjusted, but there is a laser-cut scale (nice and durable).

For border spreading, Amazone offers three variations for the firm’s AutoTS vanes: edge, border and watercourse spreading. The edge spreading vanes do throw some fertilisers beyond the border. That said, we should mention that the rate is not reduced for this application. Border spreading is for spreading along roadways. Here, not a single granule flies beyond the field boundary; however the application rate is reduced slightly. The last option is ditch spreading. Here, a clear distance is maintained from the watercourse and the application rate is reduced.

The optional BorderTS system on our tested machine was operated from a separate double-acting spool (£1,295). This swings a deflector plate behind the left-hand disc. This ensures that the entire rate is applied along the boundary. To do this, you drive directly along the border and have the left disc throw the material into the field. Then you follow the first tramline with AutoTS enabled, topping up the missing quantity to give the full rate. The BorderTS is brilliant: it allows the exact amount of fertiliser to be applied right up to the edge of the field — it couldn’t be better. When the deflector is swivelled into place, the software recognises the process and initiates all the subsequent steps automatically.

Practical weighing technology

While the weighing technology comes as standard equipment, the FlowControl torque measurement system costs £810 extra. The two systems together are called ProfisPro: this software compares the theoretical and actual application rates using the results from the weighing frame and then makes any corrections as necessary. A tilt sensor supports the technology.

FlowControl opens and closes the machine’s shutters automatically. Each application rate generates a different level of torque on the spreading disc. If this torque changes due to irregular granules, idling or a blockage, the system can automatically adjust the shutter position, regardless on which side.

Amazone’s weighing technology constantly monitors the application rate applied, which, in turn, means FlowControl is continuously calibrating and adjusting for each machine side separately. This system worked perfectly for us and seems to make sense.

In conjunction with the weighing system, the LED work lights (£660) turn into a filling aid, because one light flashes or stays on to show that you’re approaching or have reached the previously defined target weight — great.

Monitoring the distribution

The ArgusTwin option was also installed on our test machine to further optimise the lateral distribution and thus the application (almost £7,335). 14 radar sensors monitor the spread pattern and adjust it automatically. Anyone who works with heterogeneous fertiliser batches or has to spread in very humid conditions will appreciate the system. On the other hand, those who rely on big bags or invest in uniform, quality fertiliser product, can in our opinion do without this system.

WindControl is always a recommended option (£3,555). When starting work, an anemometer goes up to measure the wind direction and speed. With this data, it is possible to constantly adjust the spread pattern and thus the lateral distribution. It also uses the traffic light concept to indicate whether it makes sense to continue spreading in the prevailing conditions.

The hopper requires discipline

For anyone spreading a lot of urea, the bigger hopper is worth going for. Otherwise, the smaller hopper should be sufficient. If you utilise those 5,000 litres by filling 5 tonnes of calcium ammonium nitrate into the hopper, the whole thing weighs 5.8t and is overloaded, for example, on a Fendt 724.

We liked the ladder and the inside of the hopper. The hopper grids are made of plastic and are gentler on the paintwork than the previous steel-type grids. The good interior lighting (included in the lighting package) is also extremely helpful.

The hydraulic roll-up tarp cover on our test machine requires a separate double-acting spool. We would’ve liked this to be part of the load-sensing system. Amazone justifies keeping it separate for more flexibility.

Operation ticks all the boxes

We used the AmaTron 4 ISObus terminal including licences for GPS Switch Pro and GPS Maps (£3,990).

Up to a total of 128 sections can be switched automatically via Section Control, something many current tractor terminals still have problems with. We liked the 8-inch screen just as much as the operating concept.

We were also able to connect a tablet to it via Wi-Fi and expand the viewing area. The required AmaTron Twin app (£440) displays the GPS functions, whereas the terminal is where you operate the machine. We really liked this set-up.

The GPS ScenarioControl (£235) goes one step further in terms of machine operation. Experienced operators use this for travelling down the field and recording all of the important switching points, including the individual boundary spreading options as well as direction of travel in the individual tramlines. This ensures that, for example, less familiar operators can work without breaching regulations.

Another problem is over-/under-application on the headland, when the tractor should actually be driving straight ahead but is already turning into the tramline. Amazone solves this problem with the standard-fit HeadlandControl which increases the work width towards the field already in the first headland tramline. After that don’t forget to switch HeadlandControl off again.

Special feature autoguidance

Autoguidance was tricky with our Fendt 724 Vario, as the HeadlandControl functions exceed the standard ISObus functionalities. To ensure that everything runs smoothly, you must first activate the tractor’s auto-guidance system and only after that the HeadlandControl. If you do it the other way round, the tractor drives in the wrong bout which it retrieves from HeadlandControl. The above procedure can be automated via GPS-ScenarioControl.

The spreading settings are entered on the mySpreader app: the type of fertiliser, the work rate and spreading width, on which the app then computes the data for the various spreading scenarios. The scenarios are then transferred to the terminal either manually or conveniently via Bluetooth.

Although the user interface of the ZA-TS itself is getting a bit long in the tooth, it still offers a perfect use and everything is easy to find. Nevertheless, a facelift would bring significant improvements here. This should not be too difficult to implement.

Details in a nutshell

- The deflector screen on the BorderTS must be set once.

- There is now a reversing camera to reduce the risk of smacking into something when manoeuvring around the yard.

- Maintenance is limited to washing off and oiling. No grease nipples or chains to be greased.

- The base price of the ZA-TS 5000 Hydro ProfisPro is £31,758.

- Our ZA-TS test machine costs £52,540. The Amatron4 comes in at £3,990.

Summary

With ZA-TS 5000 Hydro ProfisPro, Amazone launches a welcome addition to the top of its spreader range.

We liked the whole machine. In addition to the very good spreading system, the ZA-TS 5000 Hydro ProfisPro boasts such standout features as AutoTS, BorderTS, WindControl and ArgusTwin as well as the Amatron4 with various extensions and the fantastic filling aid. We didn’t like the two extra double-acting spools that control the tarpaulin and BorderTS. The operator interface could also do with an update.

Lüder Görtmüller, Christian Brüse

For more up-to-date farming news click here and subscribe now to profi and save.