A Swedish team has developed a battery-powered electric drive system that recharges a vehicle in the field without it having to stop work.

There has been a lot of talk about battery-powered tractors and machines during the past few years. Few concepts have reached the market, though, possibly due to the lengthy charging times, limited operating capacity, weight and cost.

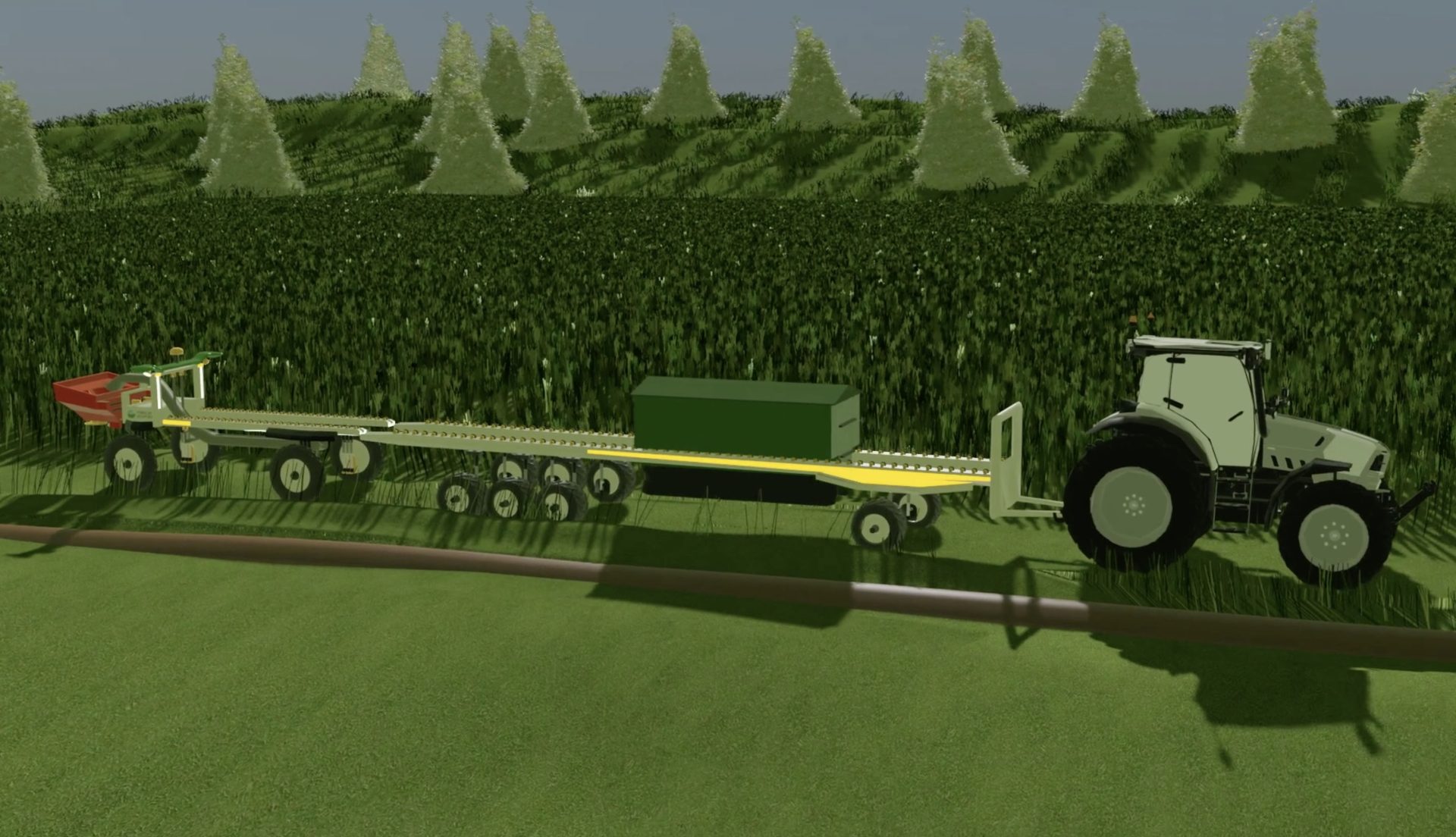

Still in the development phase, and part of the Agtech 2030 innovation platform, the patent-pending system developed by the team at Linköping university together with Stora Lövhulta and Abbotnäs farms is compatible with the electrically-powered Fieldgofer autonomous vehicle; another Swedish project.

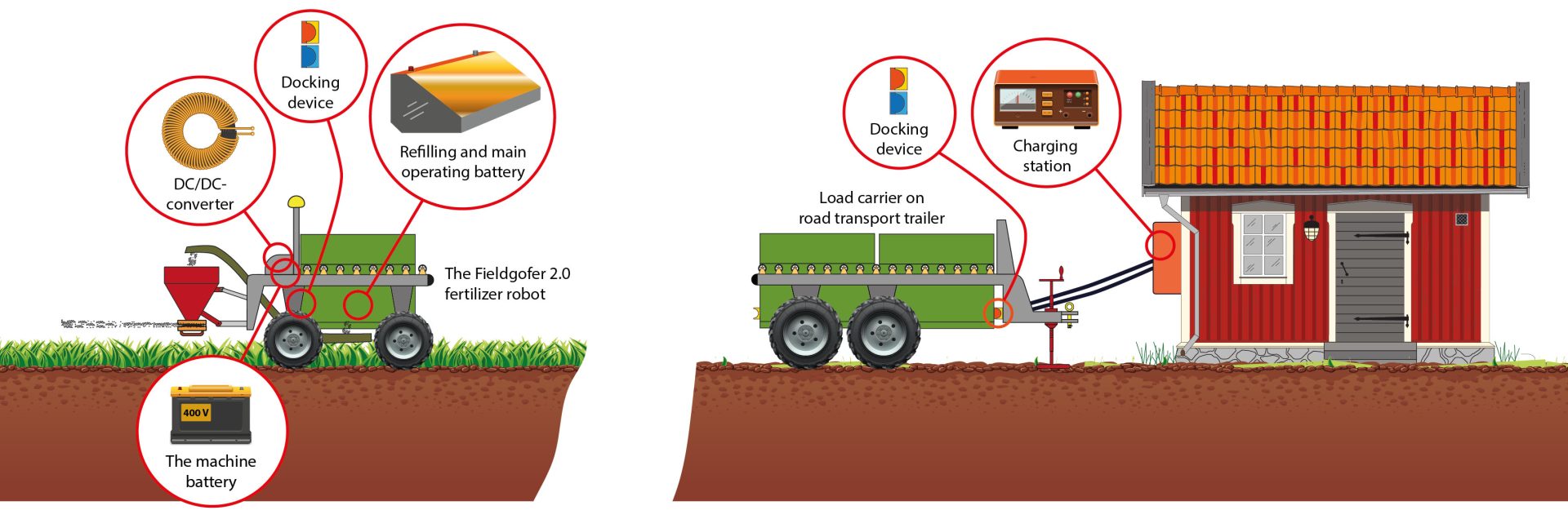

Also suitable for other autonomous and manned machines, the technique differs to all known systems in that one battery is located on the main vehicle while another (or battery pack) is integrated within interchangeable load-carrying bodies, which are filled with grain, fertiliser, seed and even manure.

Quickly transferred to the vehicle from a specially designed trailer, the main function of the batteries inside these load carriers is to power the machine’s electric wheel motors and attachments, such as a fertiliser spreader.

However, they also recharge the main vehicle battery via a DC-DC converter, and the vehicle’s main battery is only drained when the vehicle is not connected to a load-carrying body.

Specially-made trailers will be needed to transport load carriers from the field to the farm where the batteries are recharged. The Swedish team reckons at least three of them will be needed to keep the main machine working.

Working with a manufacturer, the plan is to have a fully functioning prototype in the field by February 2022. “We are very dedicated and will launch a product,” says project member and associate professor Per Frankelius of Linköping university. “We are currently looking to produce system components, such as the electric system with DC-DC converter.”

Images: Marcus Frankelius