Tweaks to the bale chamber on the new Evolution versions of the Claas Quadrant 4200 and 5000 series are designed to produce better-shaped and slightly higher density square bales. Available next season, these latest models also come with a new HD pick-up.

Wear costs on the pick-up have been reduced by increasing the use of components borrowed from the Jaguar and by reworking and strengthening bearings, intake panels and other parts. The result is said to be smoother running with lower noise levels.

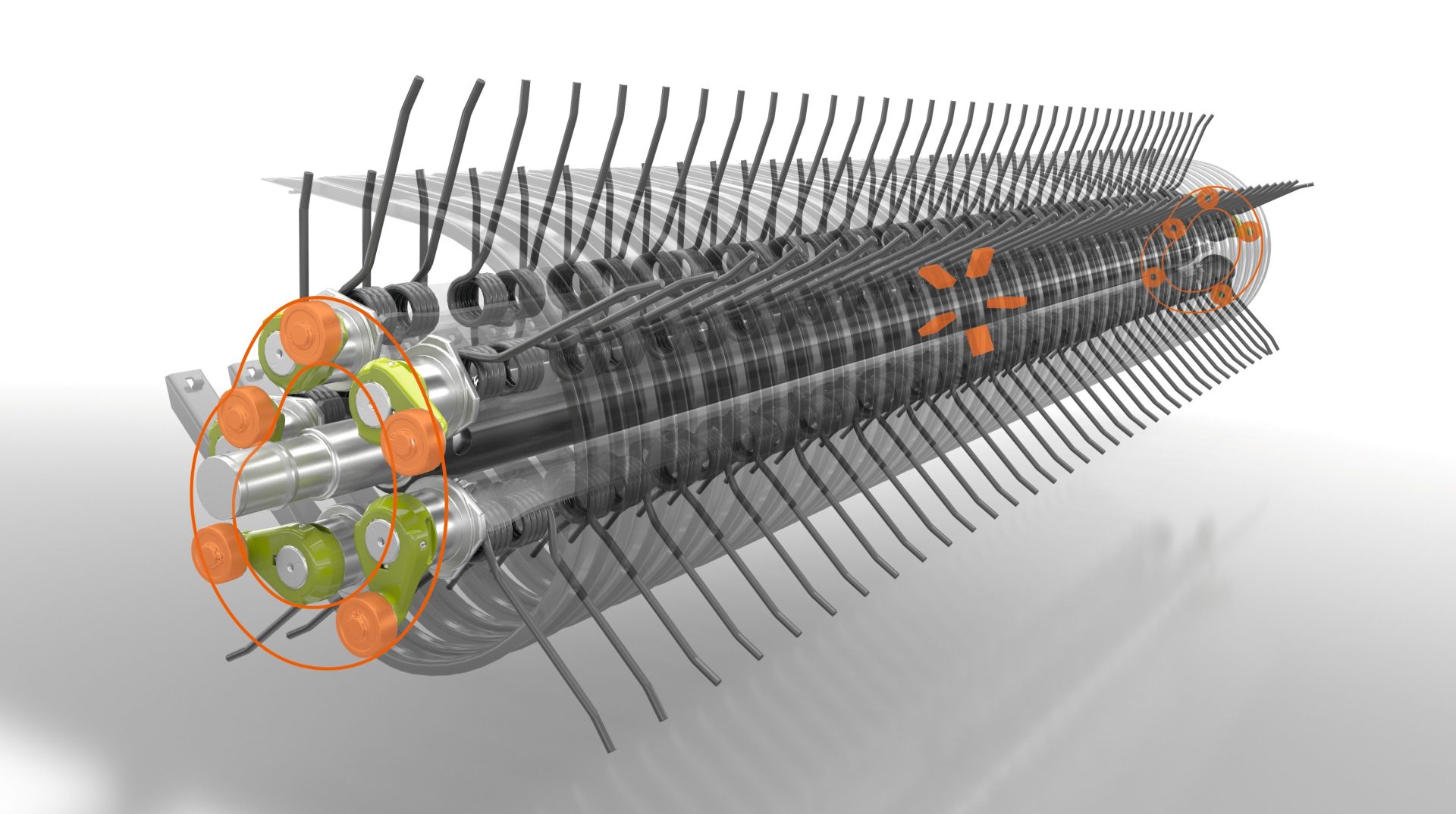

The mechanically driven pick-up with five rows of tines and 18 double tines per row has also been tweaked to increase throughput and improve raking quality. The extra row of tines allows the pick-up to rotate slower, while the speed of the Power Feeding System roller has been increased. Enlarging the diameter of the pick-up main drive shaft allows it to handle the higher throughput volumes.

The top section, incorporating the top plate and side panels of the bale chamber, has been redesigned and strengthened to produce better shaped and slightly higher density bales.

Factory-fitted sides knives and deflectors reduce material build-up in the ram guide area when baling. Claas says the knives also help to produce a smooth side to the bale removing the impression left by the ram bearing channel.

The speed of response of the automatic baling pressure control (APC) has been increased. It is also more sensitive to twine tension or load in the intake area.

The Quadrant 5300 Evolution has a new front frame and headstock, while the new hitch frame on the 4200 and 5200 provides additional hitching positions for drawbar eyes or K80. Built into the hitch frame, the new double-acting hydraulic stand is longer than the previous generation.

Modifications to the twine boxes make life easier for the operator, and a 10-litre hand-washing tank is standard. New options include being able to open and close the bale ramp hydraulically from the tractor cab. This function also enables the final bale to be ejected from the driver’s seat.

Changes to the electronic control panel are designed to simply operation. Accessed via Cemis 700, Cebis or any other ISObus-compatible terminal, just two working and three settings menus provide a better overview and faster navigation.

In auto mode, machine capacity is displayed based on average bale weight and baling pressure. Oil temperatures and levels can also be monitored from the terminal. The optional Profi Cam 4 camera allows the driver to keep an eye on working areas when reversing.