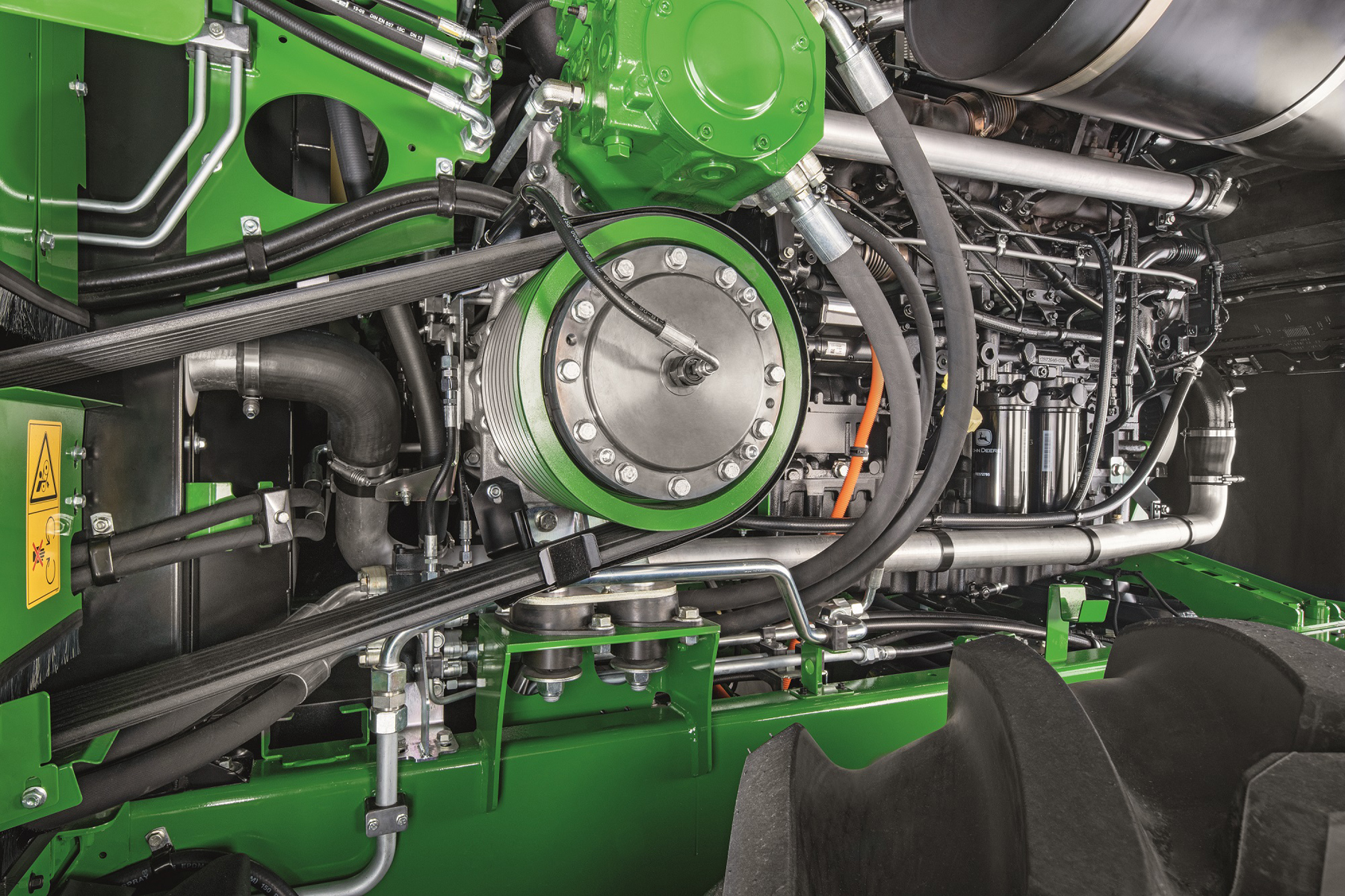

The new 9500 and 9600 self-propelled forage harvesters are the first to get the new 18-litre six-cylinder inline engine. Producing a rated 700 and 750hp respectively at 1,800rpm, the in-house made block requires no DEF to meet Stage V emissions.

The JD18X engine introduces HarvestMotion Plus, which starts to deliver more torque and power as the revs pull back below 1,450rpm, upping the available power to 766hp on the 9500 and 787hp on the 9600 (both at 1,350rpm).

It wasn’t just a matter of dropping out the big V12 block and replacing it with the new one in the two new 9000 Series models. Both are ‘wide-body’ models with the the wider 850mm chopping drum, reinforced drivetrain, improved mainframe and new and longer spout.

Kernel processor rolls are available with a standard sawtooth design on the Premium KP unit, and either the sawtooth or a new XCut design on the XStream KP, which features a spiral cut groove across the roll surface. Both roll designs are also available with the proven Dura Line heavy-duty coating for increased durability.

The two foragers are available with the full John Deere range of precision farming systems. These include the HarvestLab 3000 NIR (near infrared) sensor for real-time measurements of crop yield, moisture and other constituents which now includes metabolic energy. HarvestLab 3000 also enables AutoLOC automatic length-of-cut settings and silage additive dosing on the move, based on dry matter content. The same sensor system can be used in stationary mode for analysing clamp silage or fitted to a slurry tanker to vary the rate in relation to the slurry’s nutrient value.

Other options include AutoTrac automatic steering, MachineSync to automatically coordinate trailer speed and position with the forager. RowSense feeler guidance allows the forager to automatically follow maize rows and Active Fill Control for automatic filling of trailers.

If you want to know even more about the new foragers check-out our exclusive driving impression in the October issue which comes out next week.