Maschio Gaspardo’s move away from using the services of UK importer Opico and setting up of its own UK subsidiary has coincided with the launch of several new product lines to the British market.

While a civil relationship has been maintained (Opico is aiding in establishing the new standalone enterprise), the Italian manufacturer is keen to see a wider range of its products on offer as they are across the rest of Europe. Most significantly that includes sprayers, fertiliser spreaders, no-till drills and a wider portfolio of cultivation kit Examples of all four ranges were on the company’s stand at Cereals and interestingly it was the twin disc Primo fertiliser spinner that seemed to be getting most attention.

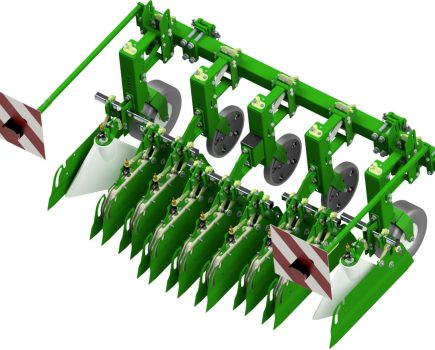

Part of a line-up which includes machines with working widths from 12m to 36m and hopper capacities from 1,270-litres to 4,450-litres, the range-topping Primo EW Isotronic on display has a twin shutter system (TSS) with one pair of sliders to deal with rate control and another to shut off the flow of fertiliser at the headlands.

Because the shutters can work independently of the rate control sliders this apparently makes for rapid shut-offs without application rates being affected. Meaning that as the spreader reaches the headland it shuts off quickly so that there’s no overlapping with the headland bout. Likewise, when spreading restarts the on/off shutters open instantly and the rate control sliders are already in the right position to accurately meter the right amount of material out according to ground speed. There is therefore no under-dosing as the spreader comes back into work.

Primo spreaders also have an eight- or 32-section headland shut-off facility. This is achieved by altering the drop point onto the disc via a three lobe hopper aperture which helps to achieve uniform distribution across the full working width even at very low application rates.

Isotronic-badged machines have the benefit of being fully ISObus-compliant which mean they can be connected directly to the tractor terminal or compatible display. As well as handling GPS-manged section control, having this on-board technology as means variable rate application is also possible with the addition of weigh cells. Not only will this facility vary the amount of product applied across the working width of the machine, it can also apply different rates to either side of the machine, adjusting flow rates to left and right discs independently.

In addition, there is the option to get an even higher level of precision with hydraulic disc drive. With the Primo EWH model, each disc is driven by its own hydraulic motor which means their speed can be controlled independently, making for yet greater section control accuracy. In addition, disc RPM is maintained irrespective of tractor engine speed or forward speed offering the potential for significant fuel savings.

For more up-to-date farming news click here and subscribe now to profi for just £3.99 an issue.