Hi-Spec Engineering’s first in-house made trailing shoe applicator is available in working widths of 6.0m, 7.5m and 9.0m.

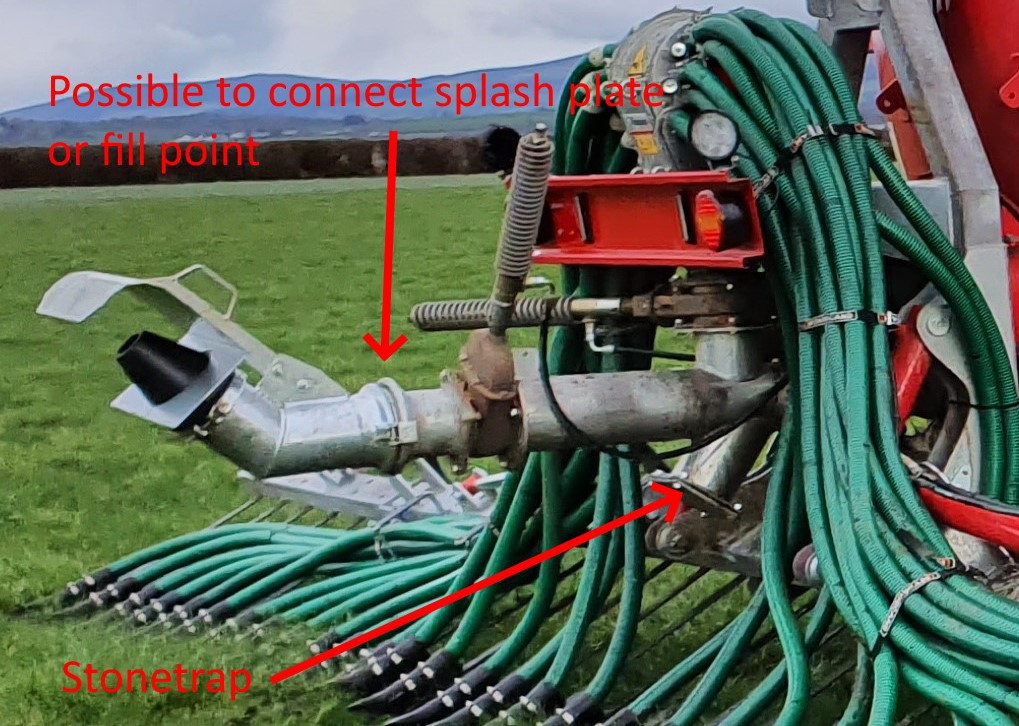

Main features include the double folding system of the two wider models to ensure that the transport height does not exceed that of a standard Hi-Spec 2600 vacuum tanker. It is also possible to use both fill points and rear splash plate without any modifications.

In operation, the hardened shoes part the grass sideways after which slurry is placed onto the ground via a rubber boot. The 9.0m units also features a hydraulic self-levelling system, whereby each arm lifts as it passes over slopes. This prevents excess pressure from being applied to the outer boots.

The company says that the grass covering prevents nutrients from escaping and the placement of the slurry to the roots ensures a reduced grazing turn-around.

The Vogelsang Exacut is used to distribute slurry to the hoses. A stonetrap on the rear of the shoe allows the tanker to be filled manually, or using the splash plate by changing a spool at the rear of the tractor. The unit can also be used as a dribble bar without any contact with the ground.

Galvanised as standard, the new trailing show applicator, which should have been launched at this year’s Grassland & Muck event, comes with an LED lighting bar for road travel.