We’ve been to France to Kuhn Group HQ at Saverne for a chat with senior management about company performance and discuss autonomous vehicles, self-propelled sprayers, mechanical hoes, dealers and more.

Times have been tough for farmers everywhere since 2013, said Kuhn Group president and CEO Thierry Krier, and this year’s conditions are challenging.

Addressing the international press at an Agritechnica preview meeting at Saverne, France, Mr Krier said that European farmers are facing another potentially dry year and North America is experiencing a very wet season.

Despite the challenging conditions, the company managed to increase sales by around 8.0% last year to just over €1 billion. Mr Krier said that Kuhn has always been profitable, wants to remain independent and be a major global player with all its product lines. “We are already a major player in Europe and North and South America, but we need to do more work in the east and China.”

“Kuhn has always been profitable, wants to remain independent and be a major global player with all its product lines,” said Kuhn Group president and CEO Thierry Krier.

The French firm has expanded rapidly during the past 20 years. In 2000, the company employed just over 2,000 staff, had four plants in France and was present in 60 countries. Today, the number of plants has increased to 11 (Brazil, France, Netherlands and the US), and Kuhn is present in 100 countries and provides jobs for more than 5,300.

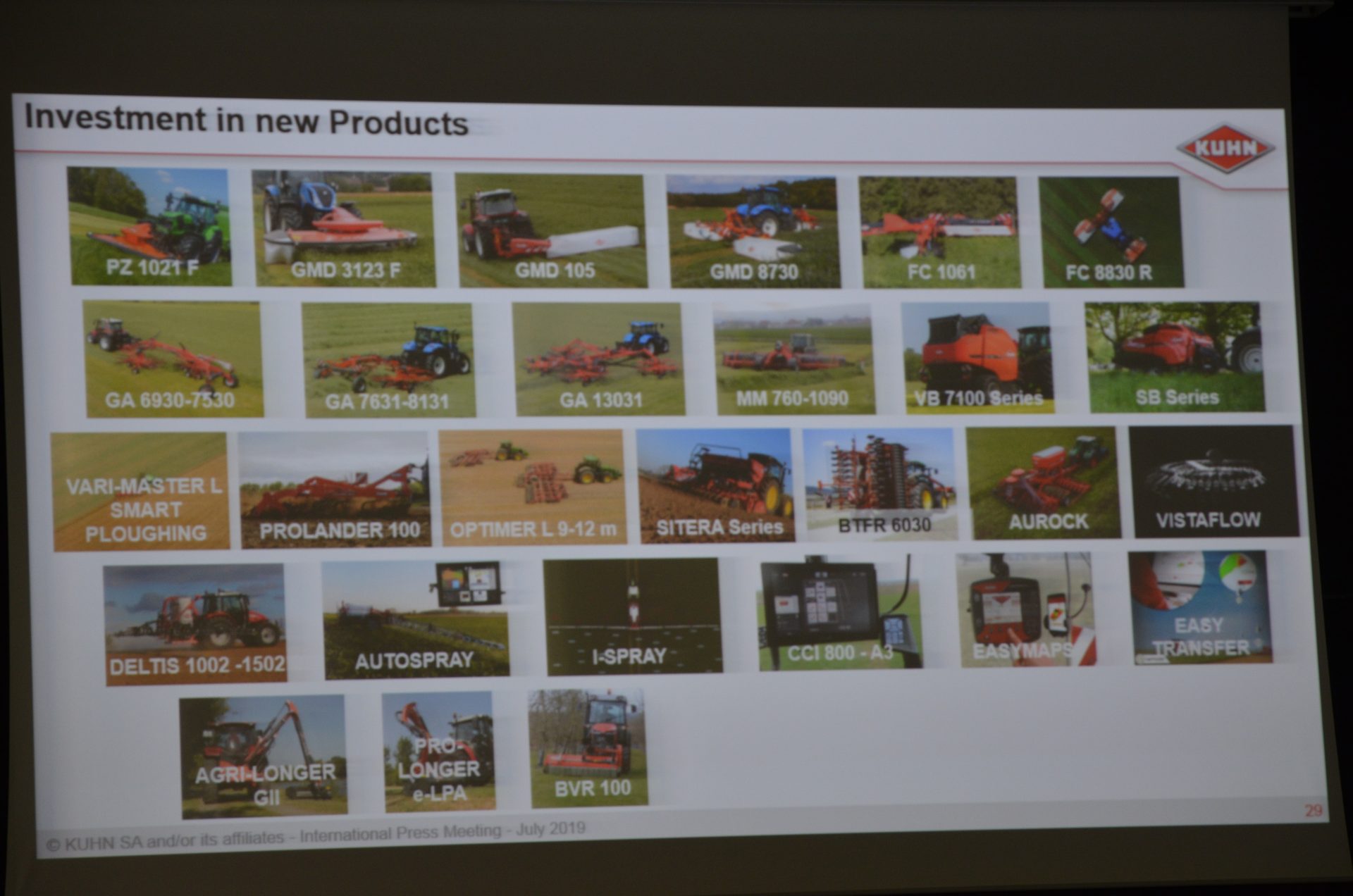

Mr Krier suggested that one of the company’s main strengths is the continued investment in its facilities and new products, and at Agritechnica Kuhn will launch no fewer than 30 machines (some of them in the latest issue of the magazine).

Kuhn will launch no fewer than 30 machines at Agritechnica.

The company invests 8% to 10% of annual net sales in R+D and capital expenditure (€28 million 2019).The biggest spend is a two-year €23 million investment extension at the Monswiller facility.

Flagged up as one of the largest construction projects in the region, it will include a warehouse extension, four new production lines and shipping area, and when finished, will double the size of the plant.

The reason for the investment is easily explained. Machine size and width has increased 30% during the past 10 years and the new plant will allow them to make more larger machines.

When completed, a two-year €23 million investment will double the capacity of the Monswiller plant.

There is another reason. The firm makes around 60,000 machines a year (1,500 base models), and 40% of all machines made today are customised.

A decade ago, this special treatment was given to just 20% of Kuhn products, a figure that increased to 30% four years ago. The percentage continues to increase. “We continue to make fewer standard products and more farms and contractors are asking for customised machines.”

Autonomous systems

Mr Krier concluded that during the last five years, farms are not only wanting to do more work, but spend less on inputs and machine costs. “We are at the beginning of smart farming and Kuhn is actively developing a number of autonomous systems.”

Unfortunately, there was no Q+A session following the press conference to discover more about these projects. However, we did have a chat with Rolf Schneider who is responsible for Kuhn Group sales and marketing.

Responsible for Kuhn Group sales and marketing, Rolf Schneider sees autonomous possibilities in two product areas – livestock feeding and crop production.

The company sees autonomous possibilities in two product areas – livestock feeding and crop production. Dealing first with the latter, Kuhn has a two-pronged approach to reducing chemical inputs.

Last year was the first in the field for the Centéol Challenge, where the firm contributed with five different implements attached to an autonomous vehicle. The results are promising, said Mr Schneider, but more test work is needed.

Last year was the first in the field for the Centéol Challenge, where Kuhn contributed with five different implements attached to an autonomous vehicle.

Second, he confirms that Kuhn is interested to find solutions reducing the use of chemicals in crop production. “Either through investments in new plant protection solutions as Autospray or i-Spray where we will present new practical solutions for the 2020 season or in mechanical weeding, either through an in-house development or via an acquisition.”

Automatic grass harvesting machines are not a priority at Kuhn, and while there is nothing official, we believe the firm is developing a number of autonomous livestock feeding systems.

While Kuhn almost has a full product portfolio, the company is keen to extend it. One perceived gap would appear to be on the self-propelled sprayer front in Europe. Last year, it acquired fellow French-firm Artec, which enjoys a third share of the French market.

“The priority is to consolidate this success, with the development and introduction of additional new products” said Mr Schneider.

“The second step will be to develop the self-propelled sprayer business in other markets, but it is not yet defined when and how we will do this.”

Finally, I asked Mr Schneider whether Kuhn is concerned about the recent developments by major tractor makers to add grassland and arable machinery to their portfolios, which could ultimately find dealers coming under increasing pressure to take them at the expense of other brands.

“We want to be seen in the eyes of the farmer as an expert and a leader when it comes to grassland, arable and livestock feeding machinery,” he continued. “The MyKuhn platform is one initiative to support this. Kuhn has no plans to make tractors or combines, but last year invested €47 million in the development of our implement specialities.”

“The focus is with large farms and contractors, evident by the new Merge Maxx and our latest developments in the four-rotor rake market and Espro min till seed drill. We will ensure that our product range is second to none.”