Fendt has not had a more powerful self-propelled forage harvester than 650hp+, since it stopped production of the Katana 85 back in 2019. Main features of the new machine include the redesigned CropFlow 2.0 system to maximise throughput and chop quality.

Claimed as the largest on the market, the 720mm diameter of the chopping cylinder with its high flywheel mass is said to ensure very smooth running and increased operator comfort. Optional chopping cylinders with 20, 28 or 40 knives are available to cover chop lengths from 2.6-41.4mm.

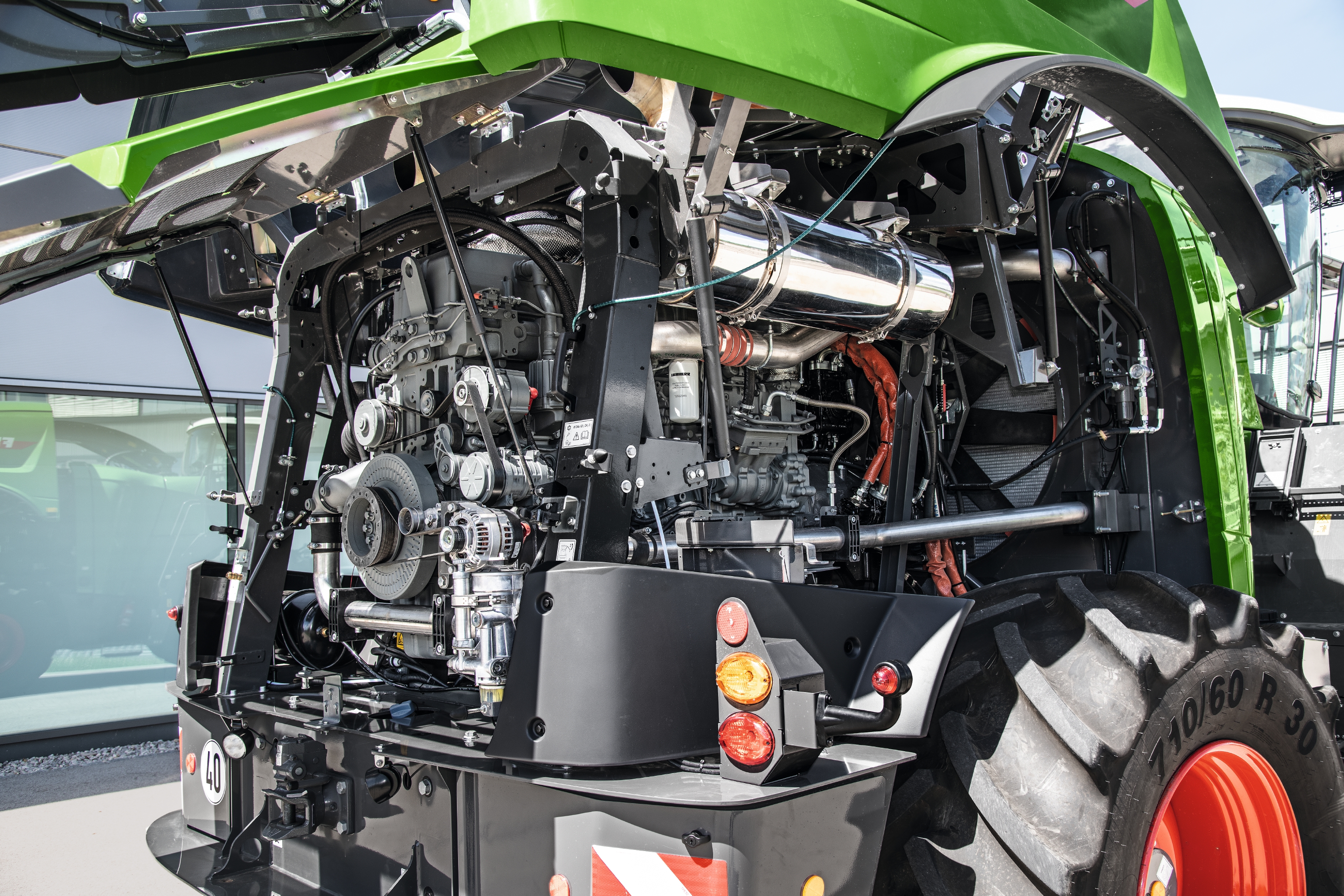

The Katana 850 can be matched to the Kemper 490plus 12-row header to fully utilise the power of the 18-litre six-cylinder 847hp Liebherr engine (the Katana 85 was powered by an MTU V12).

The Liebherr block meets Stage V emissions with SCR, but there is no diesel particulate filter or exhaust gas recirculation. If the full power of the engine is not required in can be operated in eco mode, which maintains the speed of the chopping cylinder, but then at reduced engine rpm.

Metal and stone detectors on the first of the six pre-compression rollers on the feed intake prevent damage to the chopping cylinder, and crop volume data recorded by a sensor in the rear area of the feed intake is available for yield monitoring and documentation.

Three different 300mm diameter roller crackers are available. The standard R cracker with sawtooth profile is suitable for chop lengths of up to 20mm. The optional RS cracker with V-spiral groove has been developed for longer chop lengths. The speed difference of 30 or optionally 40 percent ensures thorough processing of the crop.

The loading height of the revised discharge chute is up to 6.2m. The Fill Control filling assistance option automatically controls the discharge flap if the discharge chute swivels, to ensure trailers are filled more evenly. A camera is positioned next to the discharge flap.

Other options include a fully integrated silage additive system with 215-litre tank, the intelligent all-wheel drive BalancedGrip system, and an interface for an NIR sensor. This allows the dry matter content of the crop to be measured. An ISObus interface enables the use of different sensors.