The new 6M, 7R, 8R/RT/RX tractors and 9X combine were not the only stars on John Deere’s Agritechnica stand. Visitors were also treated to a flavour of some research projects the company is working on.

Shrouded in secrecy until the opening morning of the show, the future technology zone contained nine different electrification, autonomy and artificial intelligence prototypes.

Science fiction and something for the distant future? This was certainly not my conclusion after spending several fascinating hours talking to staff involved with the research projects of the nine working prototypes.

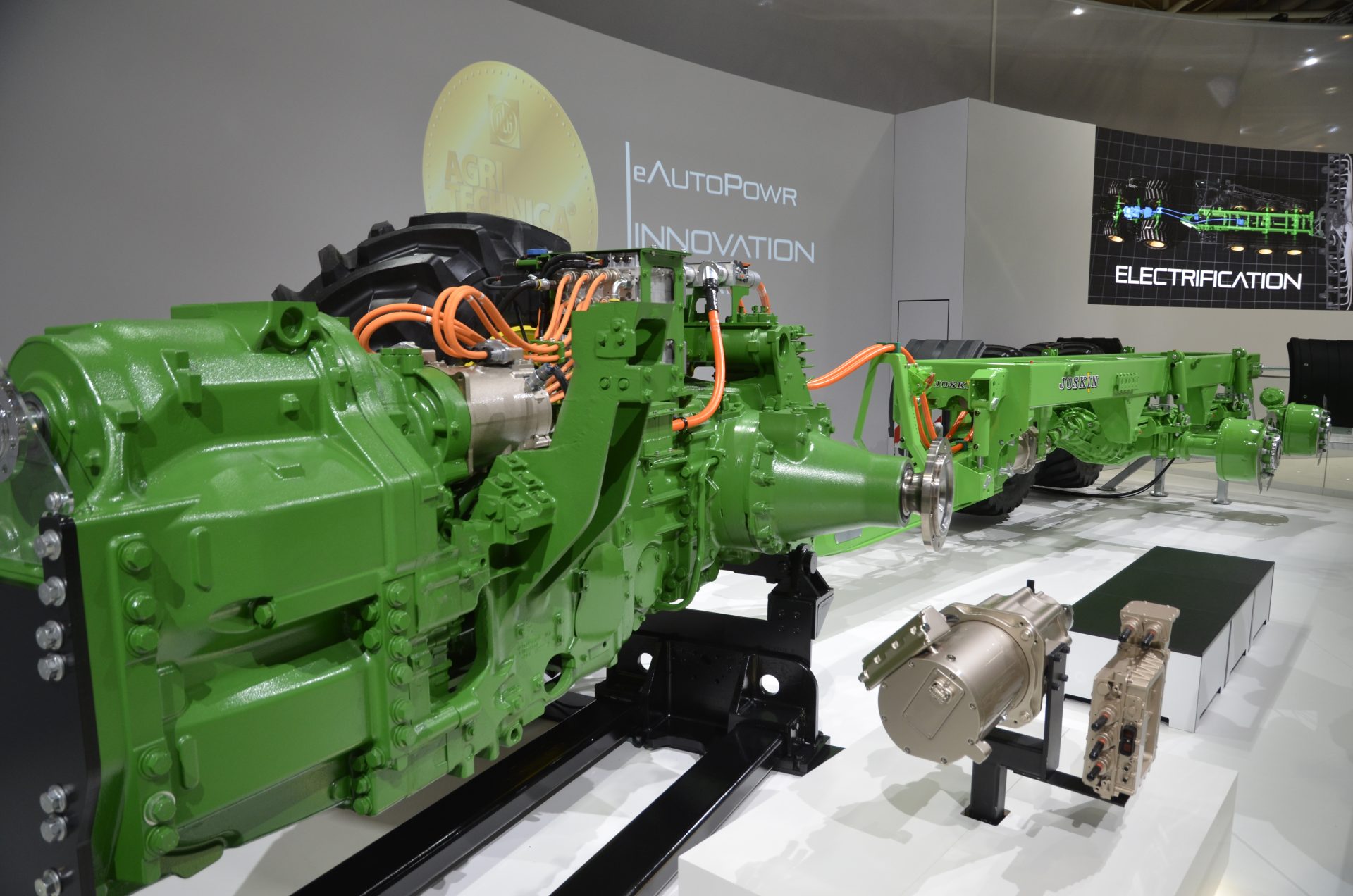

Dealing first with tractors, we knew that eAutoPowr, the first continuously variable transmission with an electro-mechanical power split, would be at the show because it was a gold medal winner. Of the nine exhibits in the technology zone, this is the only one that will be in production on the new 8 Series tractors in 2020.

Ahead of the show, we suspected that the autonomous electric tractor first seen at a dealer meeting in Valencia, Spain, in September, would make it to Agritechnica, and it did.

Codenamed as the Joker project, and a product from the Feldschwarm project, the aim of the autonomous concept, which combines a rubber-tracked (tracks from Zuidberg) electric drive unit with an integrated attachment, is to find out how much power you can put through such a vehicle.

There was an informative video on the stand, but what it didn’t show is that electricity is supplied via an external cable. The total power output of 500kW (680hp) is equally divided between the wheels/tracks and implement, and it is possible to add up to 15t of ballast to the vehicle.

Developing the autonomous electric vehicle was the easy part, we are told. The tricky bit will be to lay the electricity cables and coordinate the planning for several autonomous vehicles and the cable carrier. All the work is being done in Germany and we understand that the autonomous vehicle has already been field tested.

Continuing with tractors, John Deere also has a project to see whether it is possible for one supervisor to control up to four autonomous orchard tractors fitted with integrated crop sprayers.

Demonstrated on the front half of a 5125R, the bolt-on vision guidance technology includes three pairs of stereo cameras at the front and each side of the tractor. Pictures from these, and from a Lidar sensor, are combined into a 3D map to generate a virtual world around the tractor. The supervisor has access to all these images.

When the spray tank is empty, the tractor automatically records the precise location for when it returns. Claimed benefits of the technology include less operator exposure to pesticides and the possibility to increase productivity by over 30%.

This particular project has been underway for about two years, but we are informed that John Deere has worked with similar systems for at least 15 years.

Safety is viewed as the number one priority with all the working prototypes on the stand, and the next stage of this project to perfect this, and further test the concept, with four tractors at a North American fruit orchard where the workload of the supervisor will also be documented.

That the role of the tractor driver could change to more of a managerial one was demonstrated with the Command cab concept, which highlights new possibilities for artificial intelligence.

There is no steering wheel in this vision of the future. Instead, it has been swapped for a large central touchscreen display, which electrically slides out of the way to a lower position for road travel.

Integrated with other tractors and machines, the new operating concept integrates real-time weather data, individual pre-settings and job management procedures.

Think of it in terms of a mobile office, or ‘command’ centre, where a supervisor will manage other ‘connected’ tractors. It is not yet known how many this might be, but the joystick will be able to be used to steer them should the need arise.

A joint European/North American research project, the supervisor will be able to call up images from cameras on the other tractors and machines and even dispatch a drone to monitor progress from the air.

The company admits that it is still early days, but that it has already come a long way with digitalisation and connectivity. In fact, a lot of the digital tools used on the concept are already in use today in John Deere products.

Centre stage in the future technology zone was reserved for an electric compact tractor based on the John Deere 1 Series. A key feature is its high pto power, allowing more than 10,000m² of lawn to be mowed with one battery charge lasting 4.5 hours.

This story continues tomorrow with a look at a number of autonomous crop spraying prototypes on display in the future technology zone, one of which was a 9.2m-diameter drone!