The Skate 120 (15m) trailing shoe slurry applicator has been stamped with the ‘DLG Approved’ label passing all tests by the German organisation with flying colours.

Attached behind an 18.5m³ Fliegl slurry tanker, the Skate was put through its paces on Fliegl’s own test bench. Slurry applied during a specific period was collected in trays placed under each outlet, which were then weighed.

When spreading two types (pig and cattle) of slurry with two different outputs of 390rpm and 560rpm, average deviations in distribution quality were small ranging from 3.0-3.8% in all four test runs, which on the DLG rating scheme is very good (++).

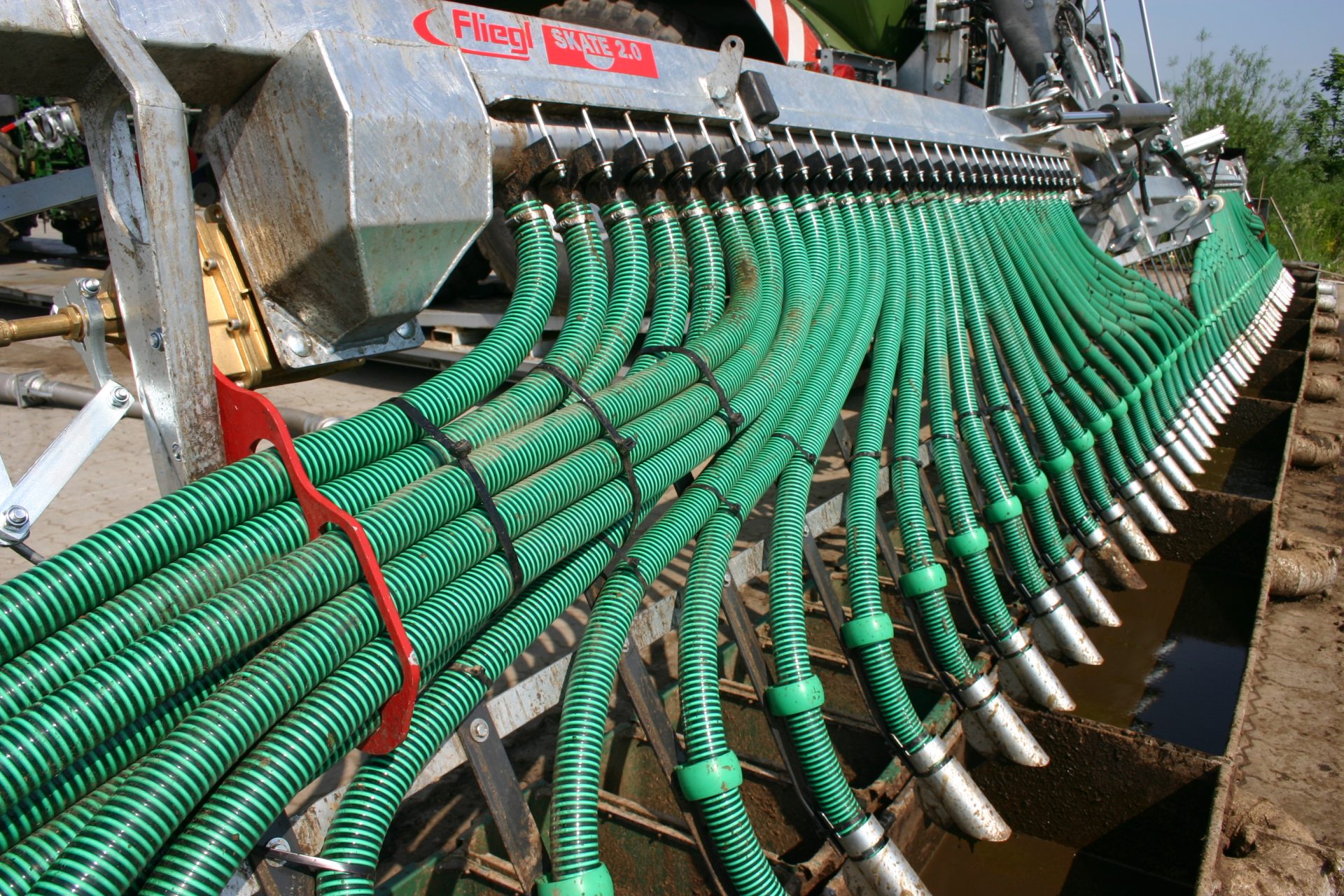

Fitted with two Fliegl distributors, each with 30 outlets spaced at 25cm, it took a maximum of just 2.6 seconds for slurry to reach all 48 outlets. As such, the applicator achieves its full working width very quickly after spreading has started.

In the handling, ease of operation, service and maintenance tests, just 26 seconds were needed to fold and unfold the Skate to its 2.6m transport width, and it took just over a minute to grease the four lubrication points. The experienced test team deemed access to all service points as excellent and most services are carried out with no specialist tools.

Available in widths of 6.0m, 7.5m, 9.0m, 12m, 18m, 21m and 24m, and suitable for use on both grass and arable land, the Skate fits behind most brands of all slurry tankers.

Main features include a coulter pressure of 6-8kg per trailing shoe along with automatic slope compensation of the central and side frames for accurate ground contour following.

Optional equipment includes a mechanical or hydraulic boom section control. Also, in addition to the standard trailing shoes, the optional twin V-shaped trailing shoe nozzles divide the slurry flow to double volumes.