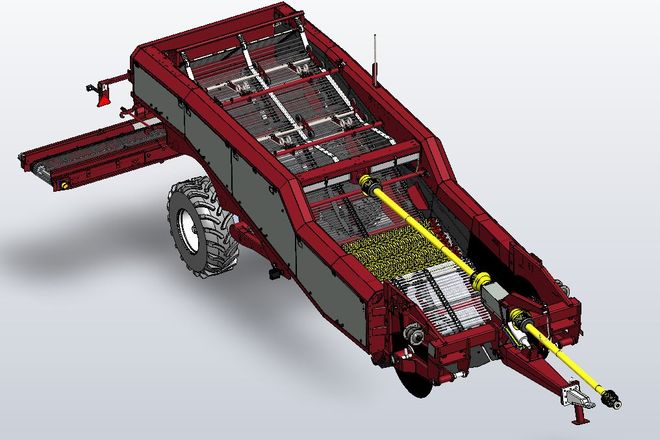

Based on the chassis of the existing four webbers, and available in working widths of 1540mm and 1740mm, ScanStone’s TriStar destoner retains the open front system with large hydraulically-operated and pressure-controlled discs.

After the share (multi-blade or full width), the material goes onto a front digger web, followed by three rows of fixed stars. These break down clods and help convey material over the webs. This combination of stars and webs is said to provide good performance in varying soil conditions.

A big feature of the ScanStone destoner range is the front intake web which, says the company, limits the wear on the front stars and drastically reduces running costs. After the stars, the soil moves onto a second web and then a rear web.

The TriStar comes as standard with a hydraulically-powered scrubber web. Rotating over the rear web, the scrubber has varying pressure, speed and direction for heavy clay or light soil with high stone content.

Operated via the latest Advanced Control System, this has a number of automated functions. These include a headland management system for start-up and shut down functions such as self-centre steering, activation of depth control, changing direction of cross conveyor and switching on the driven scrubber web.

Designed to work at speeds from 4.0-7.0km/hr, machine length is from 7.4-8.4m and weight from 5.5-6.0t, and the recommended tractor power requirement is around 160hp. The options list includes a stone box and the TriStar can be ordered with hydraulic or air brakes.