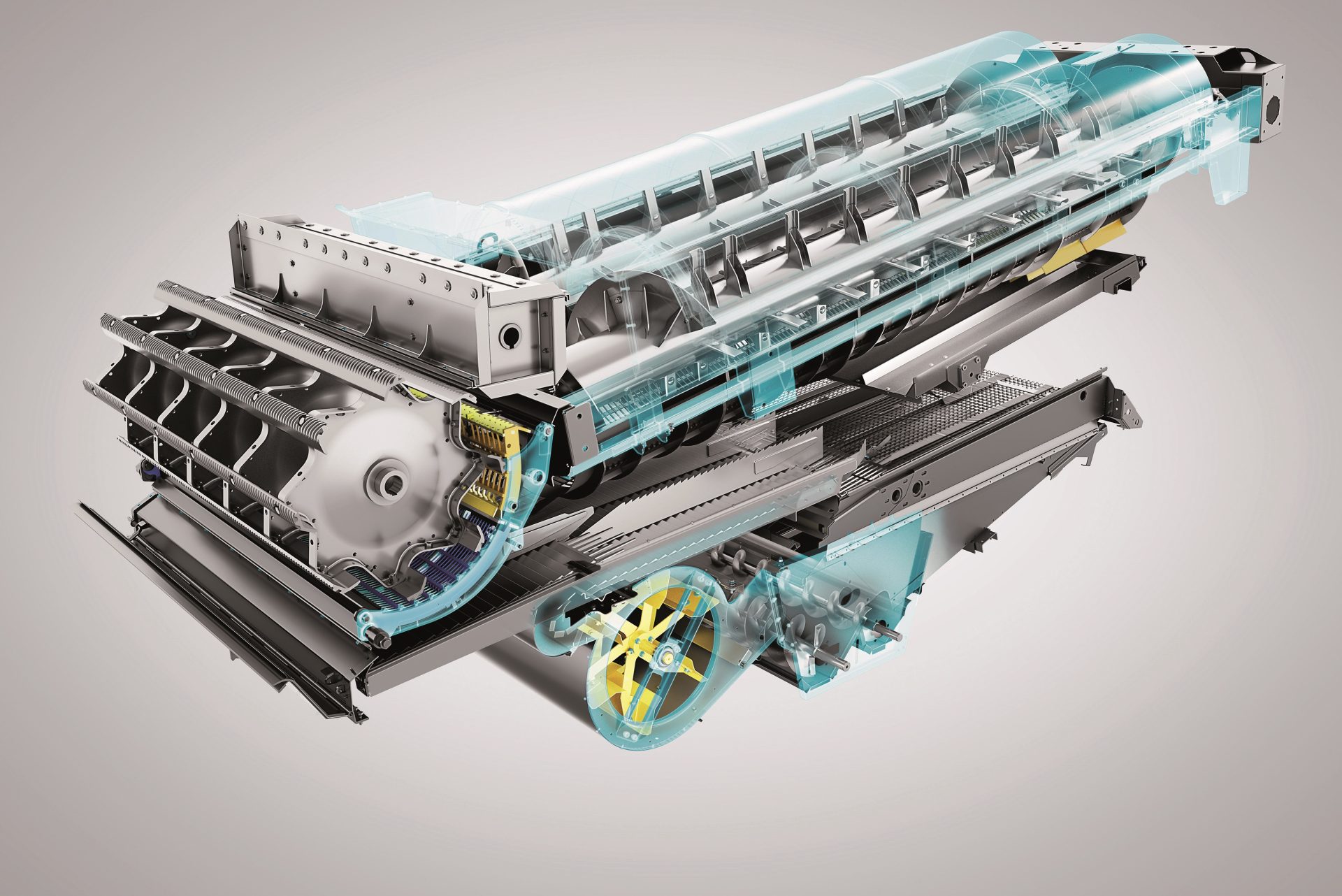

The Crossover Harvesting concept on the new CH7.70, combines Twin Rotor separation technology with a conventional threshing system. The result, claims New Holland Agriculture, sets new standards of capacity and versatility for mid-range combines.

Creating a new segment between mid-range conventional CX combines and flagship rotary CR models, Crossover technology is claimed to deliver up to 25% higher throughput than a conventional harvester in this segment.

Powered by a 374hp Stage V Cursor 9, the specially designed 3.45m-long Twin Rotor on the CH7.70 provides up to 2.9m² of separation in some segments.

The two-drum threshing system features a 600mm diameter drum with reinforced, heavy-duty design. The company says that the large drum, combined with the user-friendly sectional concave, enables fast adaptation to different crops, in less than 20 minutes. Drum speed to match crop and field conditions is controlled from the cab by a new heavy-duty hydraulic drum variator.

The threshing system is combined with the company’s Opti-Thresh system, which adapts to crop conditions and maturity simply by repositioning the rear part of the concave – no tools are needed.

The new combine can be equipped with a range of Varifeed headers of up to 9.15m, including a new 8.53m version specifically developed for this range. The SmartSieve system automatically compensates for side slopes up to 25%, and the Laterale version, which uses an automatic levelling system, provides transversal slope correction of up to 18% on both sides.

“We designed the CH7.70 for professional arable farmers and contractors looking for a combine that delivers consistent, high performance in all conditions together with low cost of ownership,” says Lars Skjoldager Sørensen, global crop harvesting product manager.

There are only four daily greasing points. The standard three-year extended warranty (1,200 engine hours) covers the engine, driveline and after-treatment system. Service intervals are 600 hours.