Continental has expanded its capacity for the agriculture sector and invested more than €2.5 million in new systems for drive belts at its plant in Hannover, Germany.

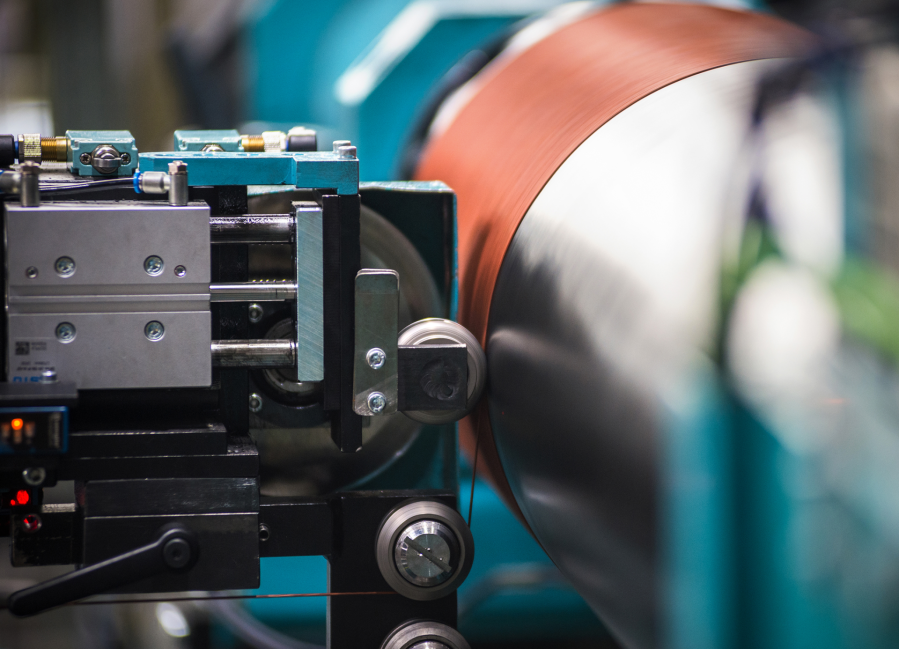

The investment includes a new production line and test rig to increase output and extend the range of applications. Already up and running, variable-speed belts include a new, smart type for machines such as combine harvesters, with an integral sensor that enables predictive, proactive maintenance.

The new line is capable of manufacturing belts in widths of up to 100cm (25cm wider than the previous maximum). The company reckons that the new size provides possibilities to make power transmission belts an alternative to chain drives on more farm machines.

The newly installed test rig tests the load capacity and robustness of the variable-speed belts up to a power output of 268hp (200kw).