Continental and Claas are jointly testing a new smart power transmission belt for combine harvesters that will allow possible defects to be detected at an early stage.

Last week, Continental revealed it was developing new smart drive belts that will increase the operational reliability of agricultural machines. We have received another press release outlining joint work with Claas to test the new belts on a combine.

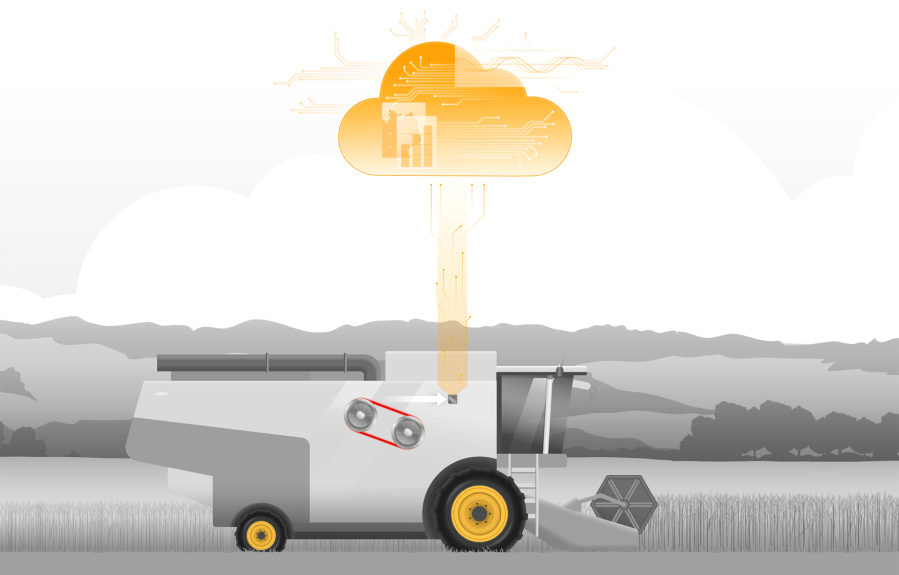

The variable-speed belt features an integrated sensor. This transmits condition-related data to a receiver installed on the combine. The data is sent to the Continental cloud and interpreted by an algorithm. It is then possible to see whether a belt is overloaded and machine settings have to be adjusted – in real time.

The early signs appear promising and the belt has already withstood some 22 million flexing cycles during harvesting tests in data gathered from 4,200ha. The electronics in the belt withstood over 140 million flexing cycles during this time.

Currently, it is only possible to check a belt after specified periods or in the event of a problem, but not while in operation. “The new smart variable-speed belt will make this possible in the future,” said Maik Zeuner, who is in charge of drive development at Claas. It will also be able to make predictions about maintenance and on the right time to change a belt.

We are not sure how much Claas will disclose at Agritechnica, but Continental is keen to discuss future potential applications for the technology.