Although part of the 6R family, the 6230R and 6250R introduce a new driving style, which we can see filtering down to John Deere’s smaller models in the not too distant future. We take a look at the Mannheim offering in the high-power, low-weight tractor category

When it came to designing the high horsepower, low weight ‘big’ 6R, John Deere did a lot of homework, seeking the opinion of potential customers to see what they wanted from this type of tractor. The end result is the 6230R and 6250R.

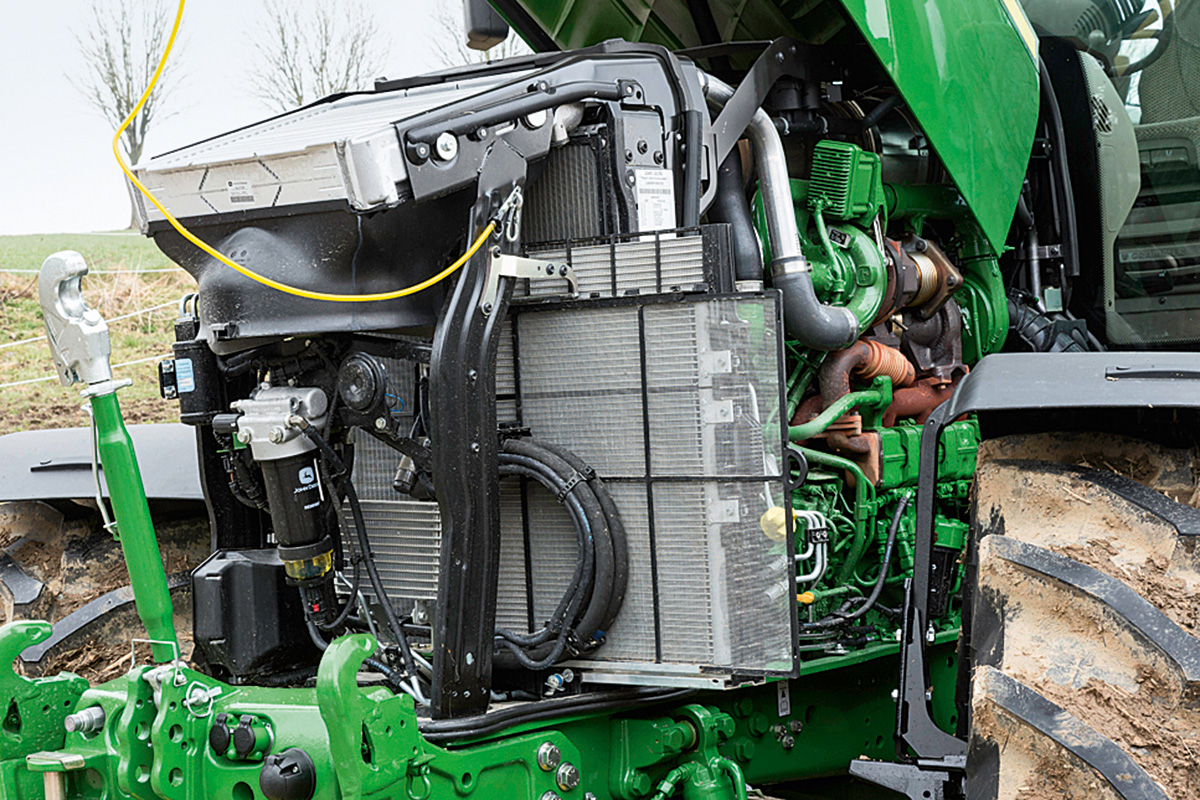

One major component that’s shared with the smaller 6R models is the 6.8-litre, DPS six-cyl- inder motor. This has a pair of turbochargers (hence the PSS tag) with variable geometry, or PVS in John Deere speak. According to the snazzy brochure, the 6250R should deliver 250hp at rated output and 275hp maximum output. In turn, the rated output can be boosted by 40hp and the maximum output of 300hp by 25hp when ground speed exceeds 15km/ hr or when operating during pto work when travelling over 2km/hr.

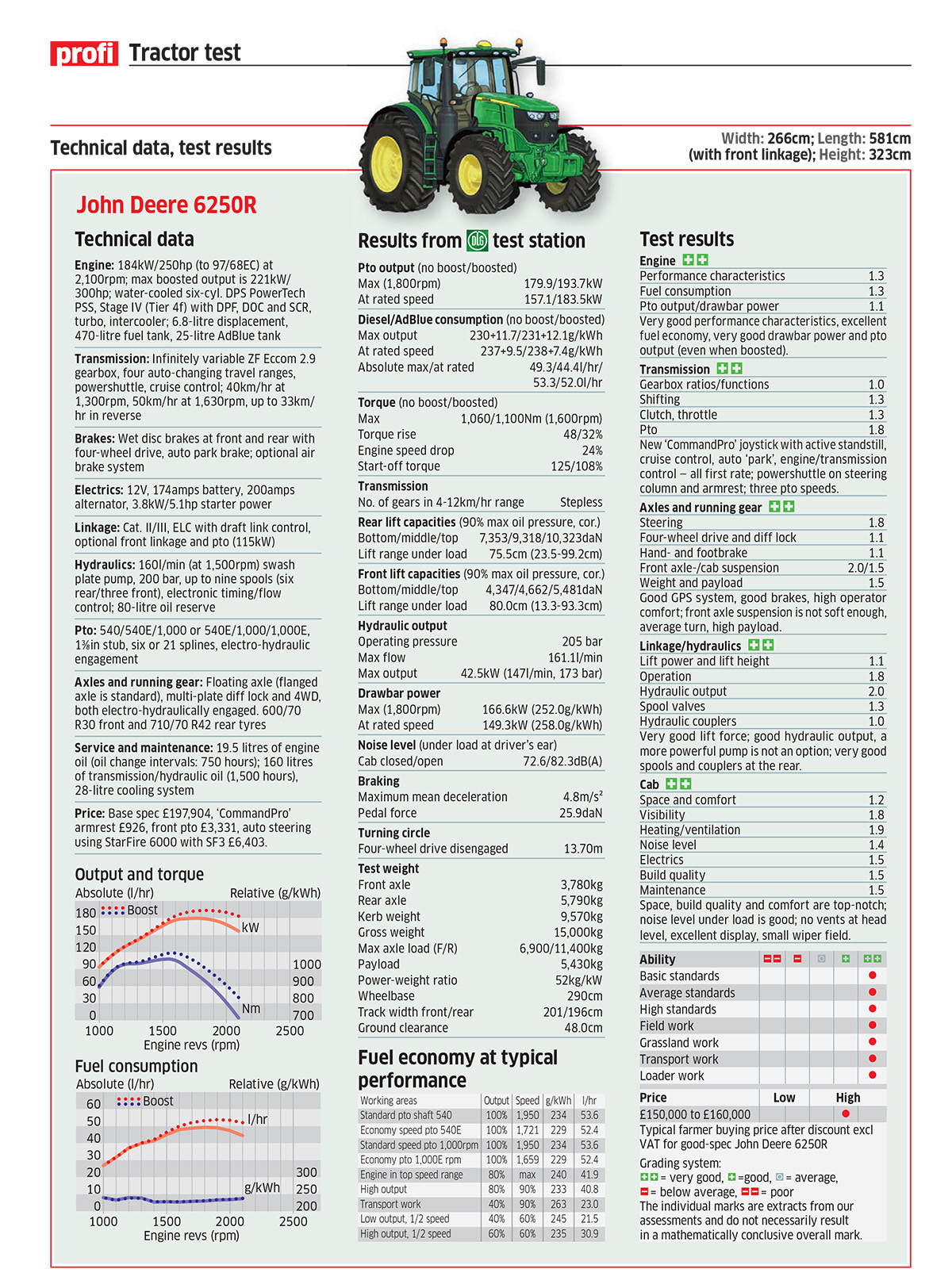

Before tucking it into practical field work, we packed our 6250R off to the DLG so the men in white coats could verify its key stats. Here at rated speed (and with the boost function disabled) the pto stub delivered 157.1kW/ 210.6hp, while at 1,800rpm it churned out 179.9kW/241.2hp — both good results, especially as the boost (after the Deere engineer had plugged in his laptop and re-enabled it) increased pto output to 183.5kW/246.0hp at rated speed and to 193.7kW/259.7hp at max output. These figures, plus a max torque of 1,100Nm, are seriously impressive.

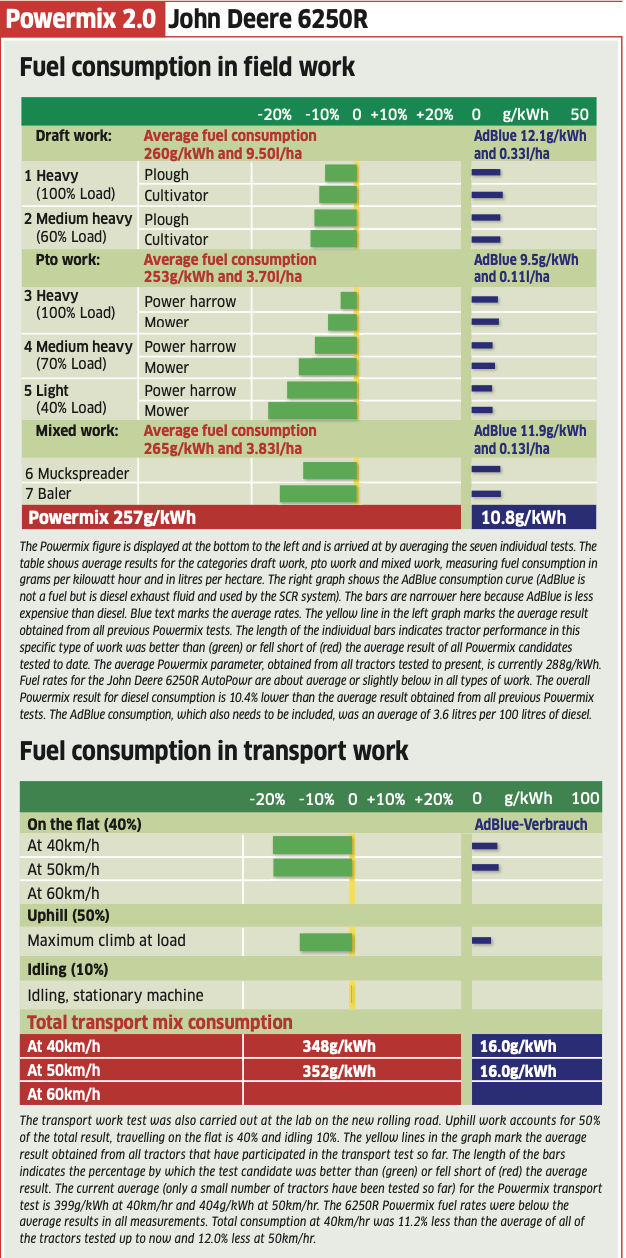

Pto horsepower measured, we proceed to fuel economy. Here again the Deere is second to none with 237g/kWh at rated speed and just 230g/kWh at maximum output. These are top-notch results, the more so as it was sipping Ad- Blue at 10g/kWh. This return further manifests itself in excellent Powermix results on the new rolling road test bed, where we can simulate typical machine applications. Here the 6250R averaged 257g/kWh (+10.8g/kWh of AdBlue), a result that is 10% less than the average rate for all of the tractors tested up to now.

Real surprises were the results obtained from the transport measurements, again using the new rolling road but this time simulating a higher load in tow. Figures for the green machine were 348g/kWh at 40km/hr and 352g/ kWh at 50km/hr, meaning the 6250R breaks all records in this test category. Indeed the 6250R’s average was 10% more fuel-efficient than any of the tractors we have put through the Powermix rolling road test so far.

No doubt the stepless Eccom 2.9 transmission has a major role to play in this performance; this box is the standard offering in the high-end 6R. The drawbar power measurements reveal it is a fairly slick unit at turning power into traction with measurements of 149.3kW/ 200.2hp at rated speed and 167.0kW/223.9hp at maximum output with fuel consumption of 258g/kWh and 252g/kWh. You will be hard pressed to find any competitor in this tractor group that can top such stats.

One of the main objections for the design team was to come up with a new armrest controller, no doubt to help woo users of other tractor makes, including Fendt operators. The end result is ‘CommandPro’, a £926 alternative to the more familiar and long serving ‘CommandArm’. This new controller comprises a chunky joystick with a totally different transmission control arrangement.

The new control stick is home to features such as active standstill, cruise control and speed memory. Using the tractor in the field we experienced the typical ‘Vario feeling’ — just as we reported in our initial driving impression in the 01/2017 issue. One reason for this is the Vario-style left flick option to carry out a direction change, while nudging the stick to the right activates cruise control and the op- tion to select the acceleration ratios.

And this ‘Vario feeling’ is even better on the high-horsepower 6R. You can switch between pedal and stick mode at any time without the need to press a button. You can also disable the cruise control by stepping on the drive pedal. In addition, at each end of the lever’s shifting gate there is a click. At the front of the gate, this click activates the set maximum speed, acting more or less like a third cruise control. At the rear the click reduces the for- ward speed all the way down to active standstill by reducing the transmission ratio.

We really liked the new driving set-up with active standstill and cruise control. All of the joystick controls are customisable 16 so operators need to concentrate on hitting the desired button

The entire engine control system convinced us during our lengthy field tests, along with the separate inching gate and the automatic park lock, which activates the trailer brakes too. Indeed ‘CommandPro’ is a major coup for John Deere. Our only quibble is you can’t select the pedal speed range from the dial.

Our test team operator discussion was dominated by the new stick which, as mentioned, is the alternative to Deere’s traditional slider and speed wheel. On the new joystick there are five flick switches, four press buttons and a dial — so plenty of configuration options which, as usual, is good for some and not for others. Those who have complex ISObus implements will love ‘CommandPro’. However, the driver not keen on bags of in-cab technology should perhaps go for the older style ‘CommandArm’.

The 6250R gets the familiar 6.8-litre DPS motor but a bigger cooling pack. Test output and fuel use were excellent. Photos ST, HW.

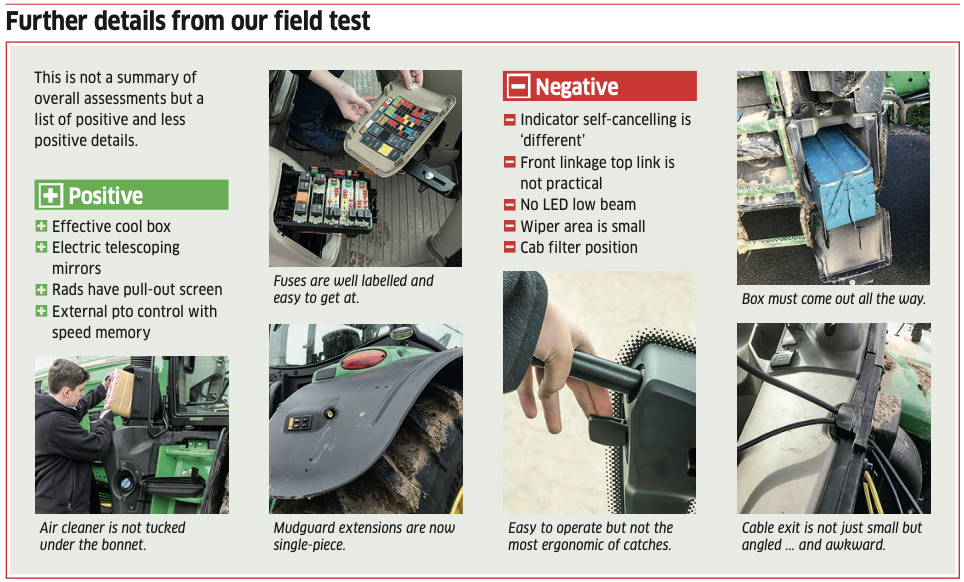

If you do plump for ‘CommandPro’, then you will find all kinds of help in the ‘access man- ager’, which ensures no unauthorised changes are made to the settings. A few of our test operators experienced a moment of horror after pressing the wrong button, something that’s easy to do as there are lots of buttons, and many look the same. Assistance isn’t far away, though: there is a decal on the cab’s A-pillar that shows the factory-set functions. The complexity of the steering system, headland and data management is discussed in a separate article in the next issue. The cab itself is straightforward enough. It is 100mm taller than on the ‘small’ 6R models, and that’s about the only difference.

A noise level of 72.6dB(A) is in line with the top class build quality of the rest of the cab, though we’re surprised that Deere has gone for a less grippy plastic steering wheel and small windscreen wiper. Back on the positive, the terminal is an example to competitors as to how display control hardware and software should be provided.

The new front linkage made a good impression with our testers, although they thought the equally new suspension system, which utilises rams on the outside, could do with providing more cushioning.

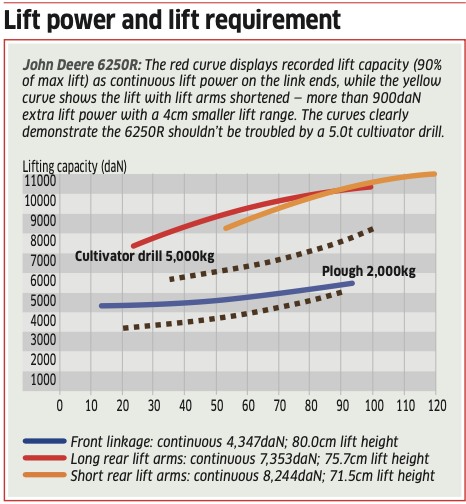

Moving to the rear of the tractor, the links haven’t changed but have received beefier rams. The linkage developed a continuous lift power of 7,300daN at the DLG test centre. With that lift power increasing to more than 10,300daN (see the graph ‘Lift power and lift requirement’) in the top range, this machine should always have enough power in reserve to tackle even the heaviest of mounted kit.

In the hydraulic department, the DLG meas- ured an oil flow of 161l/min and a hydraulic output of 42.5kW. That’s usually enough, but we would still like to see the 220l/min from the 7R offered as an option. The hydraulic oil is shared with the transmission, with a reasonable 90 litres on tap courtesy of the standard auxiliary tank.

There is no compromise with the spools — up to six couplers at the rear, or five and one power beyond coupler, all featuring a relief lever and clear identification. The front linkage also has a separate spool, and up to two more are optional.

The cab itself is straightforward enough. It is 100mm taller than on the ‘small’ 6R models, and that’s about the only difference.

A noise level of 72.6dB(A) is in line with the top class build quality of the rest of the cab, though we’re surprised that Deere has gone for a less grippy plastic steering wheel and small windscreen wiper. Back on the positive, the terminal is an example to competitors as to how display control hardware and software should be provided.

There is plenty of lift power on offer … and up to 160l/min from the hydraulic pump. The hydraulic stabilisers and couplers with relief levers are excellent.

Moving to the rear of the tractor, the links haven’t changed but have received beefier rams. The linkage developed a continuous lift power of 7,300daN at the DLG test centre. With that lift power increasing to more than 10,300daN (see the graph ‘Lift power and lift requirement’) in the top range, this machine should always have enough power in reserve to tackle even the heaviest of mounted kit.

In the hydraulic department, the DLG meas- ured an oil flow of 161l/min and a hydraulic output of 42.5kW. That’s usually enough, but we would still like to the see the 220l/min from the 7R offered as an option. The hydraulic oil is shared with the transmission, with a reasonable 90 litres on tap courtesy of the standard auxiliary tank.

There is no compromise with the spools — up to six couplers at the rear, or five and one power beyond coupler, all featuring a relief lever and clear identification. The front linkage also has a separate spool, and up to two more are optional.

Regards the running gear the big frame 6R has a 2.90m long wheelbase, rather than 2.80m, while the front axle is suspended by rams mounted on the outside. Operator comfort and the hydro-pneumatic cab suspension system were good, but we felt the front axle could do with a bit more spring to produce the optimum tractor ride.

Deceleration is very good, with brakes fitted as standard for the front wheels. The rate measured at the DLG test centre was a reassuring 4.8m/s2. The only aspect that could do with being a tad better is modulation.

With regards to manoeuvrability, shod on 600/70 R30 front rubber on a 2.01m track width, the 6250R takes 13.70m to complete a turn. Deere also offers a variable steering ratio as an option, although this was not fitted to our test steed. However, the tractor did have the intelligent four-wheel drive, which was awarded a silver medal at the 2015 Ag-ritechnica. In a nutshell, this monitors traction and, depending on axle load, wheel slip and actual speed, so that the four-wheel drive is automatically engaged/disengaged when needed. It’s a system that works well.

The same applies to the SF3 correction signal used for steering, assuming reception is good. Indeed, once in work you may wonder if those 20 LED lights are really necessary.

Thanks to a gross weight of 15t and 9,750kg kerb weight, the 6250R can offer a 5,430kg payload — excellent. This brings up the subject of tyres. Maximum size on the rear is 800/70 R38 with a 2.05m diameter, and this boot can be covered by a single-piece mudguard extension.

Lastly, prices. A basic spec 6250R carries a list price of £197,904, a figure that can spiral closer to £233,283 for a top spec tractor. Our test tractor had the standard front linkage and optional front pto pack (£3,331) — this now delivers 115kW/154hp instead of 80kW/ 107hp — the ultimate lighting package (£2,633) and AutoTrac with StarFire 6000 and SF3 correction signal (£6,403).

Summary: The big 6R from John Deere is a compact all-round machine knocking on the door of 300hp. It scores on excellent perfor- mance characteristics and sips diesel, yet the undisputed star of the show is the ‘Command- Pro’ joystick, which offers active hold, cruise control, duplicated shuttle controls and a per- fect alignment of engine and transmission. All these features combine to wrestle the control benchmark away from Fendt. Not surprising- ly, all this tech comes at quite a price, with the 250hp 6250R carrying a tag of £197,904 … or, with a few extras, a fair bit more.

This article was taken from the 8/2018 issue of profi. For more up-to-date farming news and reviews click here and subscribe now to profi for just £3.99 an issue.