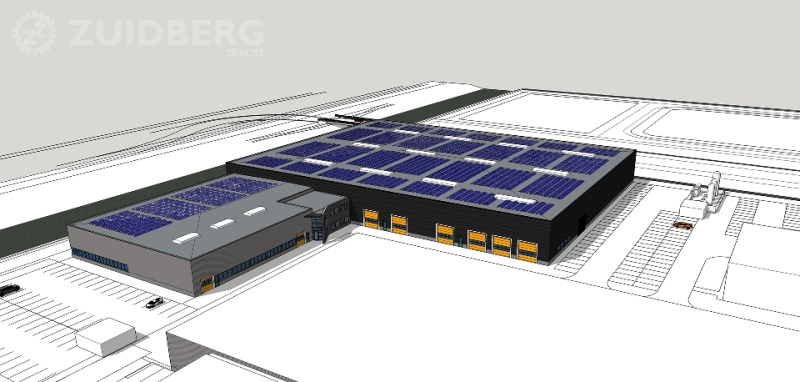

Zuidberg is building a new production facility to manufacture rubber tracks for its track systems. Covering an area of just under 10,000sq.m., in addition to the production line for the rubber tracks, the new hall will also house the assembly line for the track systems. Increasing the covered surface area at the Dutch company’s HQ at Ens to around 40,000sq.m., when finished Zuidberg claims it will be the only manufacturer in Europe that develops and produces rubber tracks for track systems. The Dutch company is confident increased awareness of the long-term negative impact of soil compaction will lead to a year-on-year increase in the number of agricultural vehicles worldwide that are equipped with track systems. However, managing director Jeroen Zuidberg says the rubber tracks currently used in Europe in agricultural applications are developed and produced on other continents. “They have been developed specifically to provide traction in heavy, high-output machines,” he says. “Our European clients have specific requirements with regard to the use of the tracks, the widths, the ground pressure and wear resistance. Developing and producing rubber tracks in-house means we are able to respond better to technical requirements, achieve a faster ‘time-to market’ and increase the added value of our track systems.” The target is to have the first European-made rubber tracks ready for sale sometime 2017.

Zuidberg to make rubber tracks in Europe

Zuidberg is building a new production facility to manufacture rubber tracks for its track systems. Covering an area of just under 10,000sq.m., in addition to the production line for the rubber tracks, the new hall will also house the assembly line for the track systems. Increasing the covered surface area at the Dutch company’s HQ […]