Flexpack isn’t a new tool. Indeed the fully mounted press has been on the market for over a decade, yet a recent revamp in its design now means it can be used with Lemken’s hydraulic auto-reset ploughs, hence broadening its appeal. We take a look.

KEEPING IT BRIEF

- Changes to the mounting brackets mean the Flexpack press can be used on Lemken Juwel 8 and 10 auto-reset ploughs.

- The leaf spring and bearings are designed for stony conditions.

- In our test, the tyre mark sank in half the amount on the pressed land relative to the unpressed ground.

- Lemken continues to offer its trailed press, which has more weight for added consolidation.

Lemken has had an integrated press for its Juwel and Titan ploughs since back in 2012. The only problem was that it could only be used with the shear bolt protected version due to how it was coupled to the plough. However, that all changes with the latest press incarnation, which has been designed to work with the firm’s hydraulic Optistone auto reset system.

The design

This new Flexpack still has a box section beam that runs parallel to the plough beam. Thanks to a movable parallelogram, if the furrow width is altered, the press alters its working width. The operator can also move the press hydraulically forwards or back, allowing the outfit, for instance, to work up to about 30cm of the field edge.

Depending on the desired firming action, the press can be pressurised with up to 100 bar. This is the maximum in order to prevent the plough from being lifted and resulting in poor penetration. If you want don’t want to press, then you can park the Flexpack in its midway (transport) position after turning the shut-off valve.

With the auto reset ploughs, you can’t raise the Flexpack up as you run through a wet spot. This is because the press is integrated into the plough’s hydraulic system and turn- over mechanism.

The Juwel plough settings will need to be tweaked if you are working with or without the press. After all, the five-furrow version of the Flexpack weighs in at 510kg and can transfer a further 400kg to the ground at 100 bar.

Details modified

Compared with the previous Flexpack, it wasn’t just a matter of changing how the new version was mounted on the auto reset ploughs with its extended pivot points; a number of other details were altered for dealing with stony conditions. For instance, the trailing arm, which attaches to each pair of rings, is now a tempered and hardened leaf spring, and the ball bearings have grown in size, too. These design changes will also be used on all Flexpacks, even those fitted to shear bolt ploughs going forward.

Currently, only 600mm high by 60mm wide pointed rings are being marketed. Other designs, such as wavy discs for heavier land, would certainly also be intriguing.

The individual ring pairs are located 14cm apart. If you want an even space between each pair of rings, then a working width of 2.66m is the sweet point. Either side of this, the ring pairs are either closer or farther apart, depending on the chosen furrow width. However, this is more of a visual issue than an agronomic one.

Working only half as deep

We tried the new press, ploughing loose, loamy sand with and without the press and then drove across with the plough raised. On the pressed plot, we were able to halve the depth of the wheel print from 18 to 9cm.

This should be a useful gauge for farmers aiming for light consolidation but not deeper firming … which you would achieve with a towed plough press. The pressing depth should be sufficient if the plough is followed by a cultivator press. In our conditions, for example, you’d have been able to follow direct with a drilling tractor using autosteer without any issues.

The biggest plus point for the integrated press is the fact that it doesn’t have to be removed from the plough for going between fields, which could mean a second tractor. The plough combination simply runs on the uni wheel. Our five-furrow plough and press were a good match for the Fendt 724 Vario, both in respect of overall dimensions and in terms of ground clearance during headland turns.

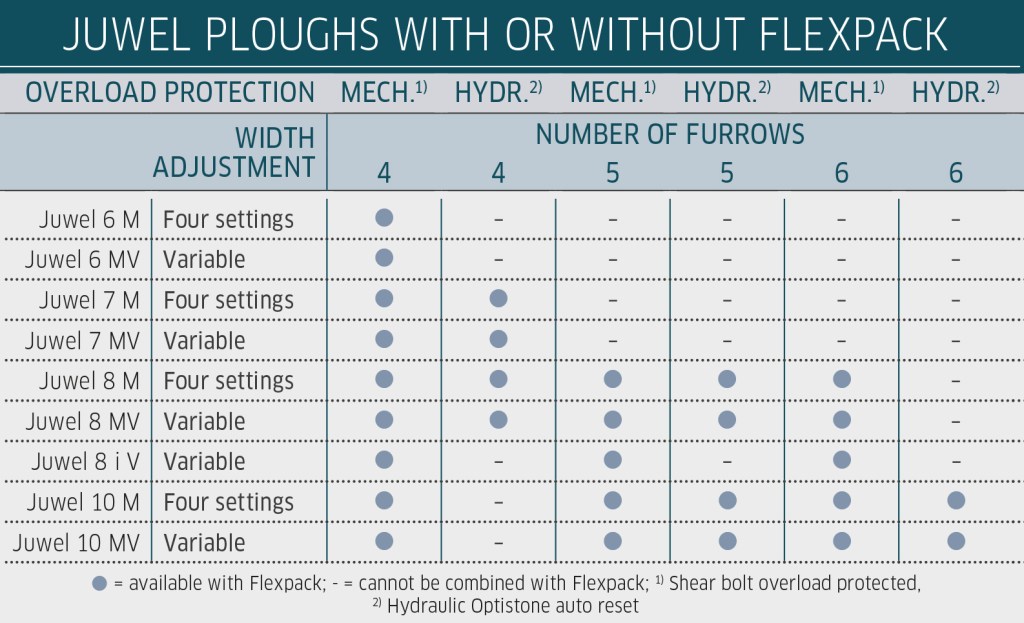

The table below provides an overview of which Juwel ploughs are compatible with the Flexpack. It is currently not available for Onland and ISObus ploughs fitted with Optistone, as these require higher turnover forces and hydraulic power.

Sönke Schulz

For more up-to-date farming news click here and subscribe now to profi and save.