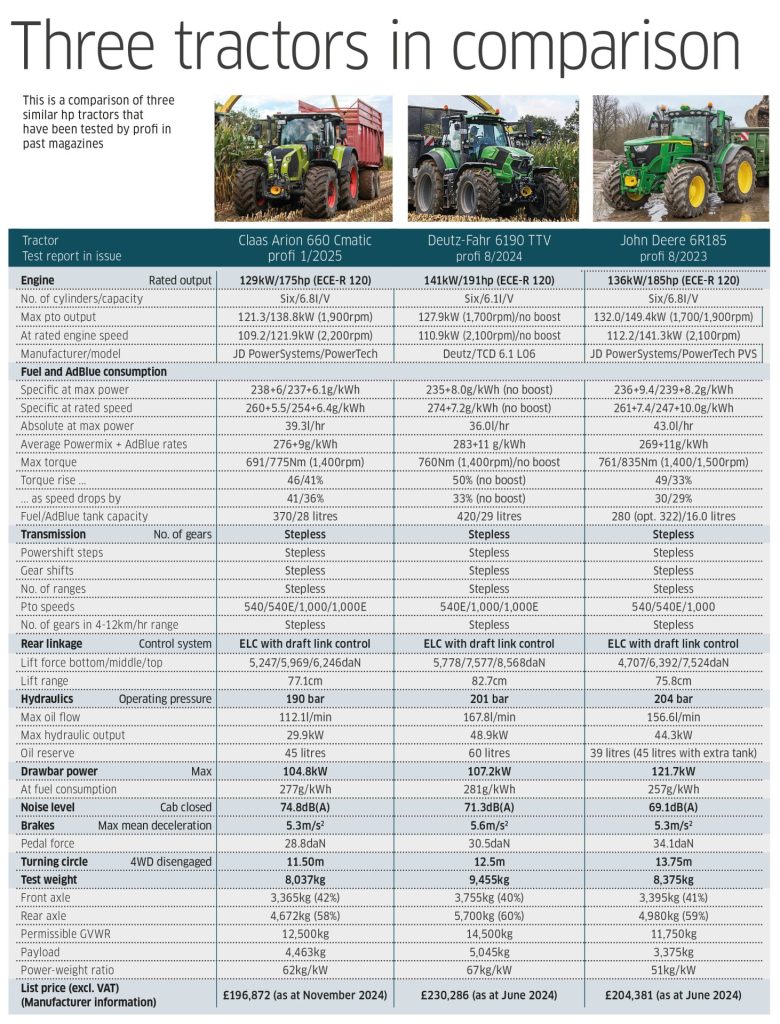

Claas has been marketing the current-shape, six-cylinder Arion for well over a decade. In fact, we tested the 650 Cmatic as far back as 2016. So, it was probably about time to have a look at the updated bearer of the Arion crown 660, for which Claas claims 200hp+.

KEEPING IT BRIEF

- Key difference between the Arion 650 and 660 is the 15kW/20hp boost… and it only comes with the Cmatic CVT.

- Performance and fuel economy are impressive and complemented by outstanding operator comfort.

- The cab is relatively short, but the ergonomics of the armrest etc are very good.

Launched in its current form in 2012, the Arion series remains bang up-to-date thanks to a number of Claas revamps including the addition of the 660 model in 2017. Not only did this coincide with some notable hardware changes, such as a new front axle and suspension, but there were also some extra ponies popped under the bonnet.

To find out if they are all there, we were keen to see the results of this month’s test Arion 660. As per the profi norm we packed our test tractor off to the DLG test centre. But before we delve into the stats, you may have noticed that our 660 is not sporting the usual Claas green but an optional metallic finish — subtle but striking, and also eye-wateringly expensive at £8,550. By comparison, the flashy chrome exhaust heat shield (£1,015) and air horn, which are all part of the £2,950 ‘Machine Package’ along with LED strobes, wheel nut indicators and aluminium plate, are almost a bargain.

In any event, our Arion 660 certainly came with the entire ‘feel-good’ package, but take note that they are not all optional extras. Our tractor was Cebis spec, which doesn’t just mean it has a screen on the end of the armrest; it also benefits from features such as a better seat, leather-clad steering wheel and an 18-light LED kit.

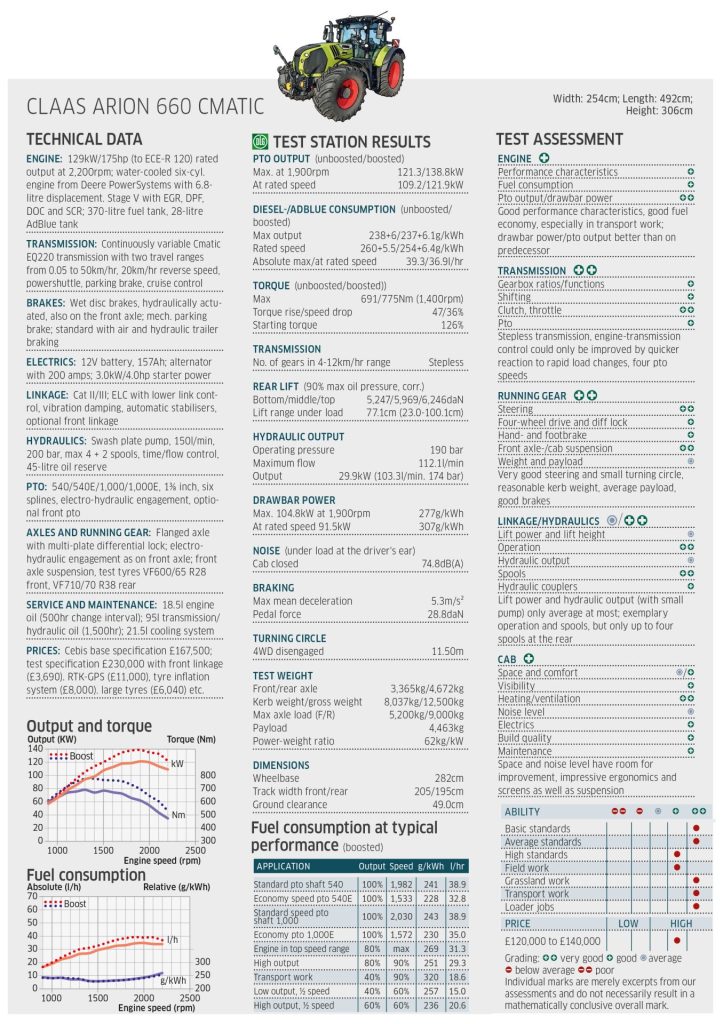

205hp with boost

As you release the easy-to-open bonnet, the first thing you spot is the easily accessible radiator pack and air filter. Tucked behind, is the proven six-cylinder, 6.8-litre Deere Power Systems power plant equipped with DOC, DPF, SCR, as well as full exhaust gas recirculation to meet Stage V.

In terms of muscle power, the brochure stats indicate 129kW/175hp at rated speed and a 136kW/185hp maximum. This can be further bolstered by an extra 15kW/20hp (CPM — Claas Power Management) which kicks in at more than 12km/hr speed or as soon as there is sufficient load on the pto and/or the hydraulic system.

So, does the 660 deliver? The test results from the DLG dyno answer that question, as we found that, at nominal speed (and with the Arion’s boost system deactivated), the all-important needle stopped at 109.2kW/146.4hp and at 121.3kW/162.7hp at 1,900rpm. These are average values.

When the boost kicked in, the pto delivered 121.9kW/163.5hp or a maximum of 138.8kW/

186.1hp at the rated speed. This means that almost 190hp from the 205hp engine makes its way to the rear stub. That’s very good! The same applies to the 47% torque rise to an impressive 775Nm.

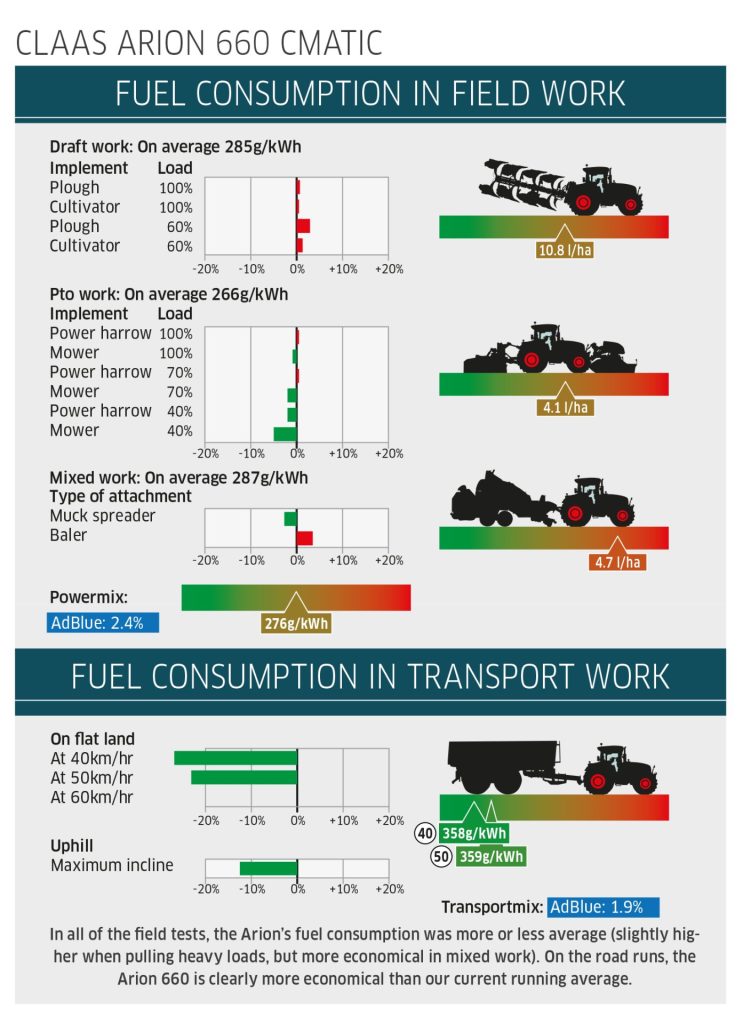

Frugal economy

This begs the question on diesel consumption. Here, too, Claas would seem to have done its homework. At 276g/kWh, the 660 proved to be more than 5% more economical in the practical Powermix measurements than the Arion 650 with 293g/kWh (profi 06/2016) in the previous Arion Cmatic test. With the newer 660, you also need to add 9.0g/kWh of AdBlue, while the 650 didn’t use DEF back then.

Looking at the individual cycles, the Arion 660 with its continuously variable Cmatic transmission has become more economical across all types of work we tested. But it is lighter pto work where the Arion stands out: for these applications it uses up to 5% less than the current profi tractor test average.

Things get even better when it comes to transport: here, the Arion 660 achieves fuel figures that are consistently 11 to 17% lower than the average — both on flat ground or in uphill work. Very good!

Claas transmission

Which brings us to the transmission. The 660 has the larger EQ220 ‘box, which, together with the software, is developed, produced and tested at the Claas Industrietechnik site in Paderborn. As a side note, the EQ200 is used in the Arion 510 to 650 Cmatic models. Its straightforward operation of three freely selectable speed bands and the good engine-gearbox control convinced the test team in nearly every respect.

‘Nearly’ because when on more demanding jobs such as with the flail mower combination or deep working cultivator, there was always two or three seconds of silence when the kit was lowered into work, the engine-gearbox control needing the time to detect the load and then increase the engine speed. Claas is aware of the issue and is said to be working on a solution.

Effective parking brake

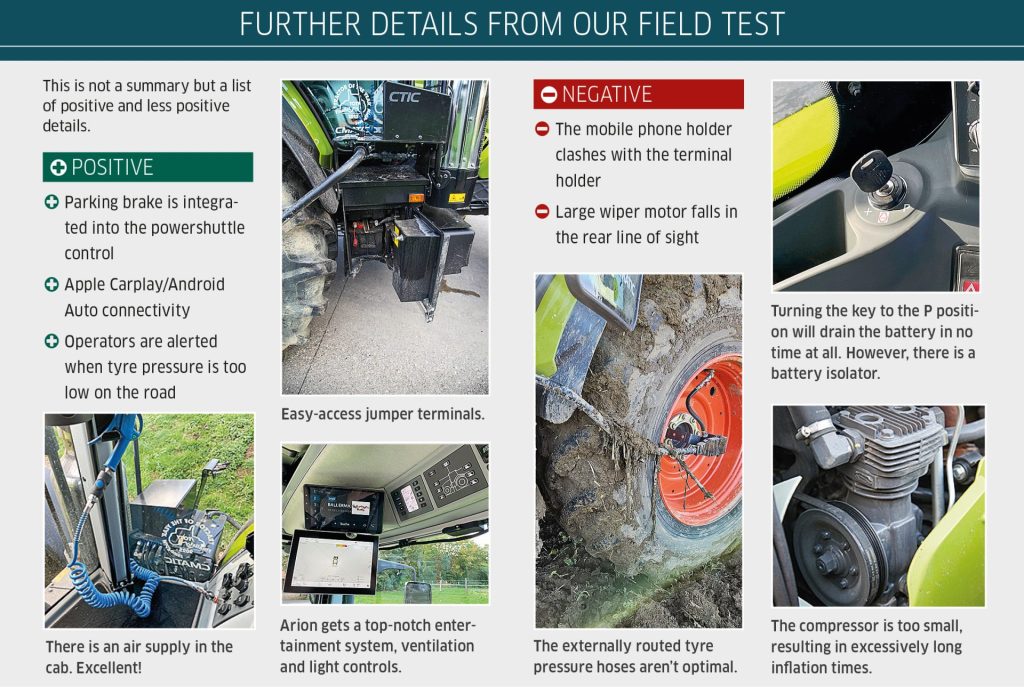

We really liked the position of the parking brake, which is handily integrated into the powershuttle lever on the left of the steering column — the extra £1,330 for this is a good investment. However, the notches on the lever for shifting it between forward and reverse are no longer up to date, especially as there are shuttle buttons on the Cmotion control and hydraulic cross control. Sadly, these only work when the powershuttle lever is in neutral — annoying!

Otherwise, our testers’ ‘like’ list included things like the four pto speeds with dry stub change. Another nice detail is the fact that the engine speed memory is linked to the pto. Frustratingly, this only applies when the pto control is pressed from the ground. The fact that the pto shaft shuts off automatically when you overspeed is still not practical; for example, when you want to use the 540E at more than 600rpm. Not something everyone will want, but it’s nice if you do.

Decent spools

Good news is that the 150l/min swash plate pump is standard on some versions of the 660, but our tractor had the smaller 110l/min pump. Even so, the DLG test centre still measured a maximum flow of 112.1l/min and a max output of 29.9kW. That’s a brilliant result for a 110l/min rated pump, though we still think it is worth getting the bigger pump for a tractor in this power bracket.

As for the hydraulic system, a 45-litre oil reserve (shared circuit) is just as good as the up to four spools at the rear and two at the front, all with time and flow control. We also liked the programming and the display. More than that, there’s also no need to reactivate anything after starting the engine. And 75% of lever travel can be used for proportional control even if the timer function is selected. Excellent.

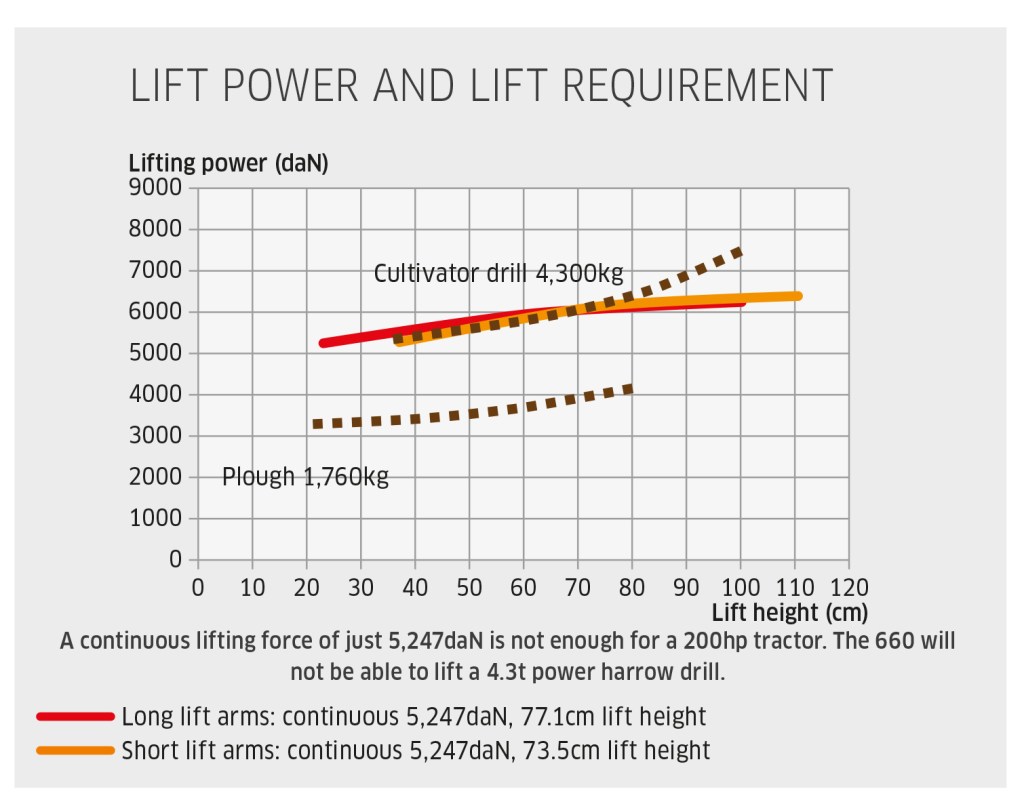

More lift power, please

Compared to the 2016 test on the 650, Claas has raised the position of the cross shaft and the top link coupling point on the rear linkage to improve lift performance. Nevertheless, a continuous lift force of exactly 5,247daN, as measured by the DLG test centre, is not sufficient to hoist a 4.3t power harrow drill (see, the graph above, ‘Lift power and lift requirement’). This means that the Arion 660 may not be able to lift implements that it has the power to drive.

There is a lot of praise for the quick linkage controls. The cross button on the Cmotion lever offers all the usual options, but, when it comes to changing settings, Claas still relies on dials on the B-post. While they offer quick adjustment, it does mean you cannot save settings for different implements that can then be recalled for the next time you are using them.

On the other hand, the much improved anti-rotation stop on the top link pin is a step in the right direction. However, the Arion still lacks a simple factory-fit solution for altering the spacing of the lower links from Cat. II to III and back again.

The front linkage has position control and can be operated from external buttons. In the last test, the DLG measured a continuous lifting force of 3,352daN — that’s fine. A front pto can be retrofitted at any time without having to replace the radiator or other parts. And the front pto can cope with full engine power — great.

Cab — good and bad

Compared to some of its competitors, the Arion’s cab can no longer be described as ‘spacious’. Even drivers of normal height often have the seat pushed all the way to its rearmost position where it fouls with the back of the cab wall.

Otherwise, the cab is pleasingly up to date, mainly thanks to the ergonomic armrest with Cmotion joystick. All function keys and the screens fall into place. One point of tester discussion is the steering system, which requires a second terminal, and the fact that kit working widths etc. have to always be entered separately. So, there is room for finessing here.

Claas says it applied a UV protection tint to the rear window as well as an extra layer of insulating material under the floor. This has made little difference to the noise level: 74.8 dB(A) at full throttle is no better than the previous test in 2016, but the background noise is much more pleasant. In any case, the ride comfort, thanks to four spring struts under the cab and the suspended front axle, is top-notch.

Payload limited

The front axle was changed some time ago. Instead of the good — but high-maintenance — Carraro axle with independent suspension, the Arion now boasts a full-width Dana axle with trapezoidal suspension. This combination operates perfectly and provides good ride stability as well as a larger ground clearance (we measured 49cm). Its agility is impressive, too: a tight-ish turning circle of 11.50m along with a 2.05m wheelbase and VF600/65 R28 tyres is great!

In terms of weights, we weighed a base spec 660 at exactly 8,037kg. Although the gross weight is only 12.5t, the nominal payload is almost 4,500kg, but this quickly drops below 4,000kg on a fully specced tractor with front hitch, front pto and large wheels etc.. This is definitely not enough for this power bracket. Claas needs to make improvements here as soon as possible.

Our test tractor was running on VF710/70 R38 tyres along with the factory-fitted CTIC tyre pressure control system (profi 09/2022). This reduced the pressure from 2.0 to 1.0 bar in just 50 seconds — on all four wheels. Brilliant!

Inflating, though, requires quite a bit more patience (unless you opt to order the larger CTIC 2800 additional compressor): it takes more than twelve minutes to go from 1.0 to 2.0 bar when using the (undersized) standard compressor (for the air brake system) at full throttle. We also regularly had the problem that, after starting the engine, the electronics would not detect the tyre pressure system as an ISObus system.

Summary

The Claas Arion 660 will quickly become a favourite of many drivers thanks to its ride comfort and ergonomic controls. While the engine power and economy tick all the boxes, the tractor does lack a number of things, at least on the largest model, such as available lift capacity and payload. In addition, Claas’s tyre pressure control set-up with an external air supply is not yet optimal.

Bottom line is that if the cab grows a little bigger, and integration of the auto-steering system gets better, this smart all-rounder will be right up there among the sector’s leaders. To be fair, it’s already there on price, which, at £230,000 for the pretty much fully kitted out test tractor, represents quite a hefty wedge.

Hubert Wilmer

For more up-to-date farming news click here and subscribe now to profi and save.