Next season’s Jaguar 900s are available with the new V-Flex chopping cylinder. Other updates include a new rear axle, an automatic trailer changeover function and revised knife sharpening system.

Optional to the standard V-Max on 900/900 Terra Trac models, the V-Flex enables the chopping cylinder to achieve higher throughputs with reduced noise levels. Available in four versions with 20, 24, 28 and 36 knives, crop flow is noticeably more consistent, says Claas, especially for chop lengths over 12mm.

The V-Flex can be run with a full, half or third set of knives, or with a set of half knives, with chop lengths ranging from 3.5mm to 53mm. Fitted with newly developed and patented knives, the extended 23mm thick anti-wear coating is said to significantly extend the service life. All chopping cylinders can be used for harvesting maize in combination with the MCC Classic and MCC Max as well as the MCC Shreadlage corn crackers.

The updated knife sharpening system includes a new function whereby in addition to individual functions for knife sharpening and shear bar adjustment, there is a combined function that enables both to be completed in just one minute.

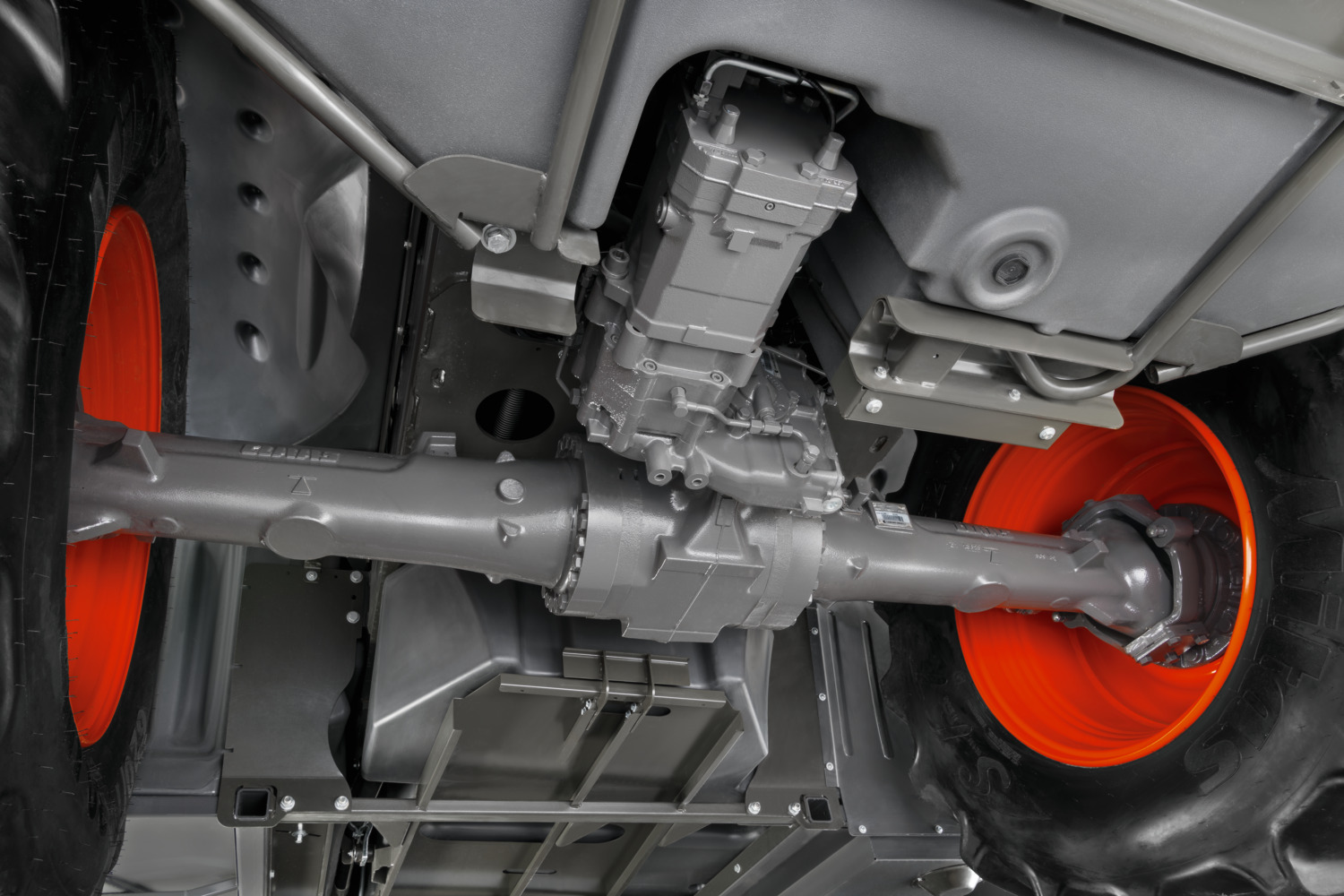

With a load capacity of 9.0t, the 10-hole rims in the Power Trac variant of the new Carraro rear axle enables 4wd to be engaged under load. Wheel spacers of 460mm (standard axle) and 620mm (Power Trac 4wd axle) are available to widen the track.

The sensor-based shear bar adjustment has also been optimised. A display showing the process time, status description and visualised process is now available in Cebis for all sequences. Claas says that this enables operators to better estimate downtimes and make optimal use of waiting times.

The automatic trailer changeover function for Auto Fill is also new. Activated by double-clicking a button on the CMotion control lever, the discharge flap then directs the crop stream to a preset position at maximum speed to reduce losses and make life easier for operators and trailer drivers.

Until now, the CSPS value (Corn Silage Processing Score), an indicator of kernel processor performance, could only be determined in a lab. Not anymore because a new app allows it to be done in a field while harvesting. To calculate the scores, a litre of chopped material is collected and divided into a minimum of five individual samples on a blue plastic A4-sized tray that comes with the test kit.

The samples are then photographed with a smartphone and transferred to a server for analysis. The results are returned a few minutes later – enabling on-the-move corn cracker setting adjustments to be made.

Other updates for next season include the 300 series pick-up. Equipping the newly shaped intake auger with four offset paddles is said to result in a more uniform crop flow, and the extended one-piece dust screen, which swings open for maintenance, covers the full working width.

For more up-to-date farming news click here and subscribe now to profi and save 47%.