ISObus is not without its issues, such as when a tractor and implement refuse to speak to each other. We show what should be possible today … and the limits.

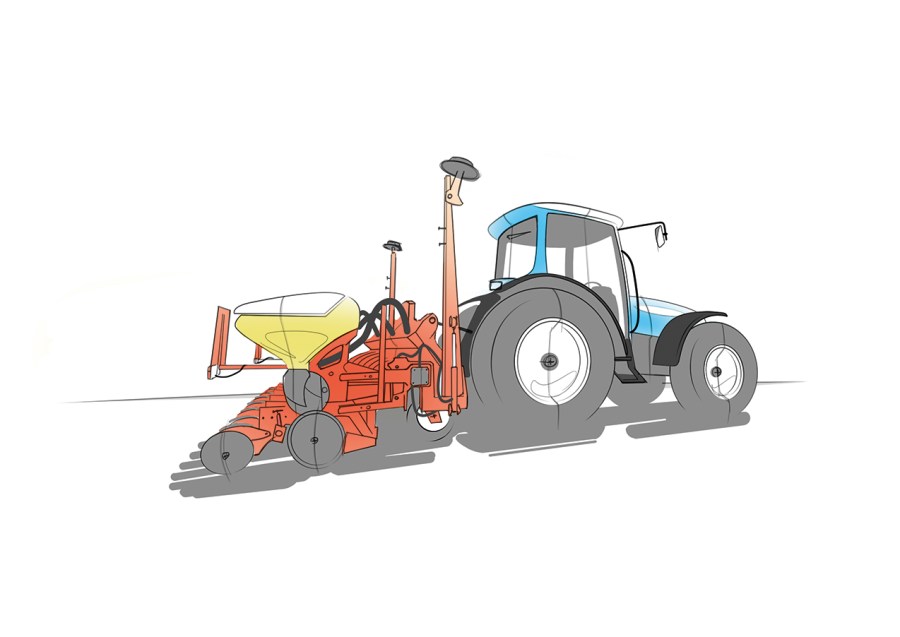

Usually, the in-cab screen is the only part of the system that’s visible, but ISObus is so much more than just a one-connection terminal. Several components need to speak to each other to make the ‘buttons’ you are pressing work. At the heart of the system is the job computer on the implement and the screen (UT) in the tractor.

The job computer controls the main functions: application rate, section control or something much simpler such as lifting and lowering a pick-up. If connected to an ISObus-compatible terminal, the job computer will tell the screen which icons go where and what other info needs to be shown to the user.

ISObus is based on the CANbus (Controlled Area Network). Each connected client (UT, job computer, etc.) is given a Bus address and communicates with the other clients. What sets ISObus apart is that larger amounts of data can be transmitted. On top of that, there are two 12V circuits, each with two terminals, to power any electric drives that are on the implement. The two larger circuits supply up to 60 amps to large

consumers such as metering units on a drill or lights. The smaller circuit is protected by a 30-amp fuse and supplies the power to the job processors.

For more up-to-date farming news and reviews click here and subscribe now to profi for just £3.99 an issue.