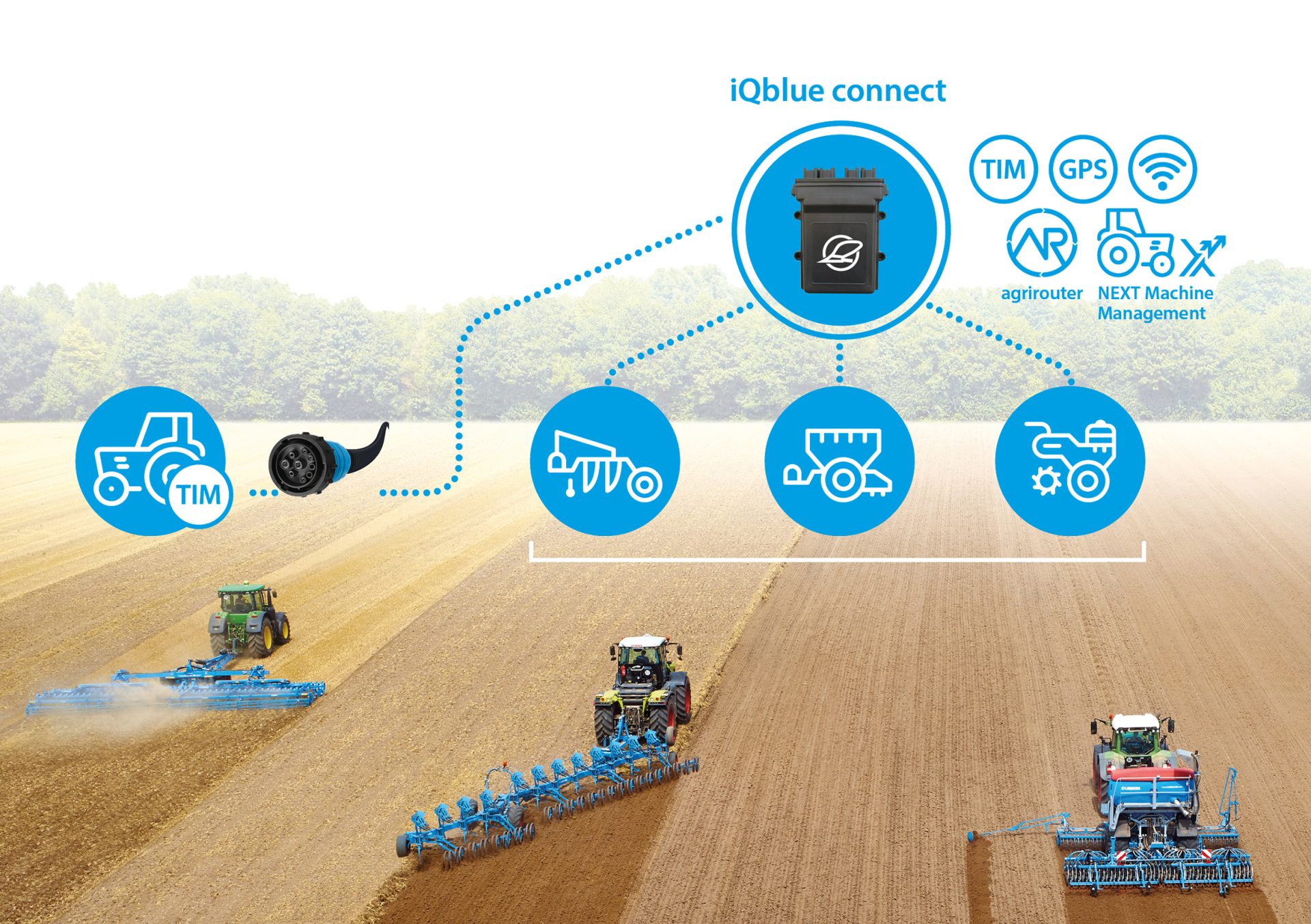

Lemken’s IQblue connect module, a device that allows soil-engaging implements to automatically control a tractor, has received AEF (Agricultural Industry Electronics Foundation) certification for Tractor Implement Management (TIM).

Connected to the tractor via its ISObus interface, users only need a single module, as the mobile unit can be transferred between implements without requiring special tools.

Allowing the implement to control certain tractor functions, such as spools and forward speed, the first step with ploughs is GPS-based working width control where implement data on the position and working width are transmitted to the TIM to enable the hydraulic control unit on the tractor to automatically control the plough’s working width cylinder.

This ensures that the plough always produces a precise and straight furrow, says Lemken, and helps to increase efficiency when ploughing wedge-shaped fields.

For semi-mounted cultivators, the working depth can be detected by a sensor. In this case, iQblue connect collects the area-specific target working depth from digital maps, and the TIM adjusts the working depth of the tine section and levelling tools to the changing soil conditions in the field via the tractor’s hydraulic system.

Suitable for retrofitting to existing implements and compatible with implements from other manufacturers, the Agritechnica silver medal winning device, which can only be used on tractors with AEF-certified TIM functionality, will be available from October on current and older ploughs with hydraulic work width adjustment (V and Vari versions).

This includes all mounted Juwel (V) and VariOpal, the semi-mounted Diamant (V) and VariDiamant. It is also available for semi-mounted Karat cultivators.